Conveniently-cleaned recovery treatment apparatus for rare earth waste liquid

A technology that facilitates cleaning and recycling. It can be used in separation methods, process efficiency improvements, chemical instruments and methods, etc. It can solve problems such as troublesome cleaning of recycling devices and affect the quality of recycled rare earths. The effect of convenient speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

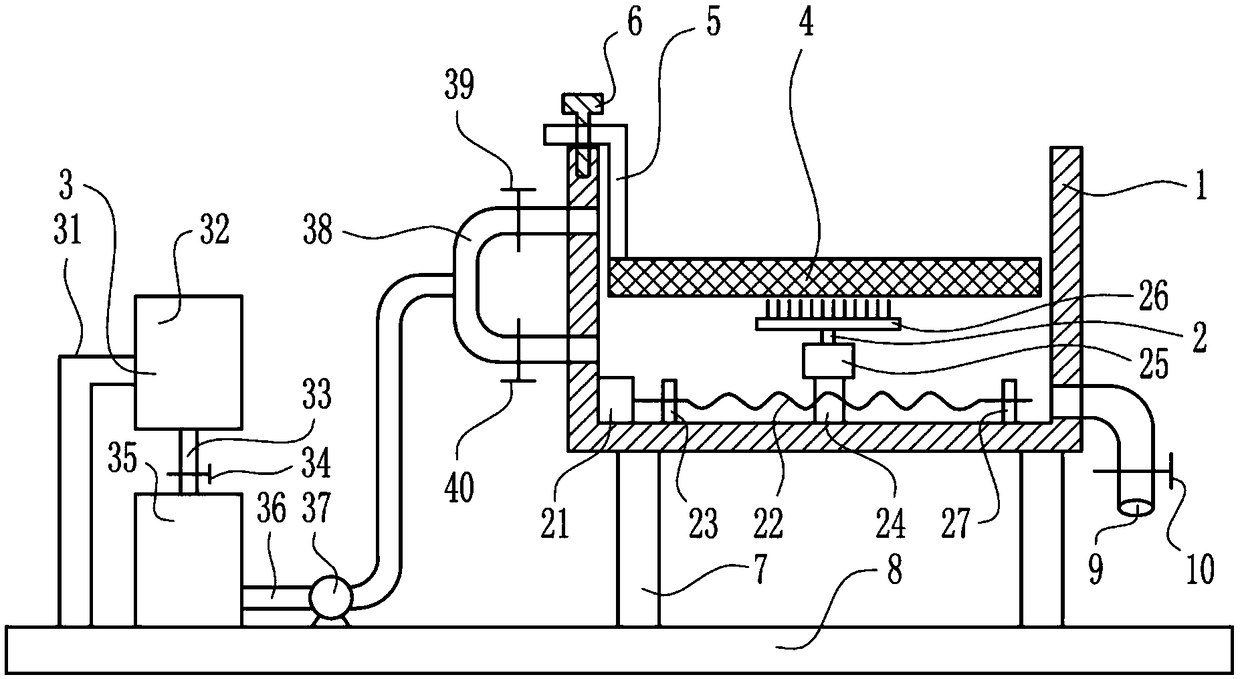

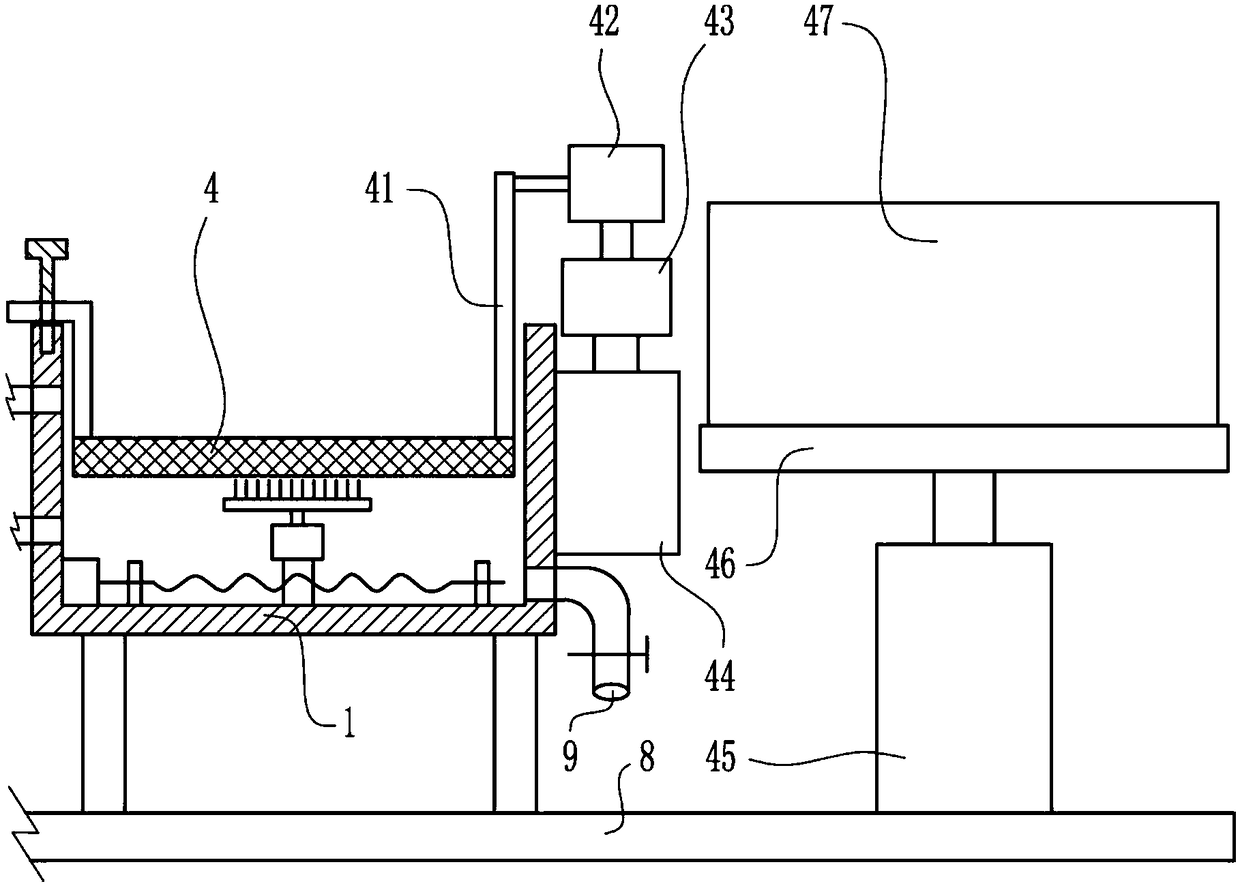

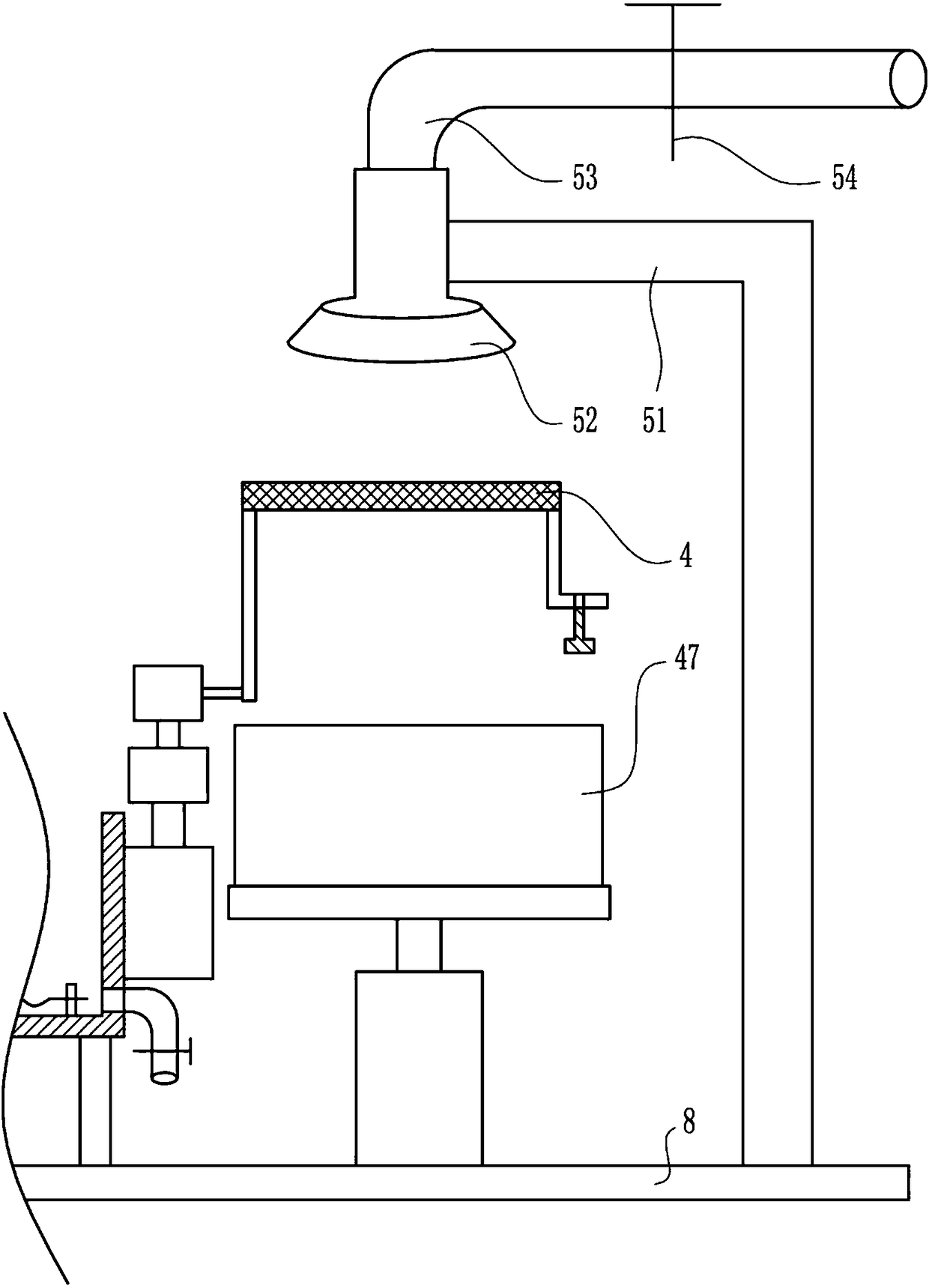

[0027] A convenient cleaning recovery and treatment device for rare earth waste liquid, such as Figure 1-3 As shown, it includes a filter cylinder 1, a cleaning device 2, a conveying cleaning device 3, a filter screen 4, an L-shaped connecting rod 5, a positioning bolt 6, a leg 7, a base 8, a liquid outlet pipe 9 and a valve I10; a filter cylinder 1 The lower part of the inside is provided with a cleaning device 2, a conveying cleaning device 3 is provided on the left side of the filter cylinder 1, and a filter screen 4 is provided in the filter cylinder 1. The filter screen 4 is made of steel wire mesh, and the filter screen 4 is located above the cleaning device 2. , The left end of the top of the filter screen 4 and the lower right end of the L-shaped connecting rod 5 are connected by welding, the bottom of the upper left part of the L-shaped connecting rod 5 and the top of the left side wall of the filter cylinder 1 are arranged in an active connection, and the left side of...

Embodiment 2

[0029] A convenient cleaning recovery and treatment device for rare earth waste liquid, such as Figure 1-3 As shown, it includes a filter cylinder 1, a cleaning device 2, a conveying cleaning device 3, a filter screen 4, an L-shaped connecting rod 5, a positioning bolt 6, a leg 7, a base 8, a liquid outlet pipe 9 and a valve I10; a filter cylinder 1 The lower part of the inside is provided with a cleaning device 2, a conveying cleaning device 3 is provided on the left side of the filter cylinder 1, and a filter screen 4 is provided in the filter cylinder 1. The filter screen 4 is made of steel wire mesh, and the filter screen 4 is located above the cleaning device 2. , The left end of the top of the filter screen 4 and the lower right end of the L-shaped connecting rod 5 are connected by welding, the bottom of the upper left part of the L-shaped connecting rod 5 and the top of the left side wall of the filter cylinder 1 are arranged in an active connection, and the left side of...

Embodiment 3

[0032] A convenient cleaning recovery and treatment device for rare earth waste liquid, such as Figure 1-3 As shown, it includes a filter cylinder 1, a cleaning device 2, a conveying cleaning device 3, a filter screen 4, an L-shaped connecting rod 5, a positioning bolt 6, a leg 7, a base 8, a liquid outlet pipe 9 and a valve I10; a filter cylinder 1 The lower part of the inside is provided with a cleaning device 2, a conveying cleaning device 3 is provided on the left side of the filter cylinder 1, and a filter screen 4 is provided in the filter cylinder 1. The filter screen 4 is made of steel wire mesh, and the filter screen 4 is located above the cleaning device 2. , The left end of the top of the filter screen 4 and the lower right end of the L-shaped connecting rod 5 are connected by welding, the bottom of the upper left part of the L-shaped connecting rod 5 and the top of the left side wall of the filter cylinder 1 are arranged in an active connection, and the left side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com