Active noise reduction system and method for trains

An active noise reduction and train technology, applied in the field of rail transit, can solve problems such as the lack of better elimination and processing methods, affecting the riding experience of passengers and drivers, etc., to reduce the weight of the car body and manufacturing costs, low hardware cost requirements, and flexibility overlay effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

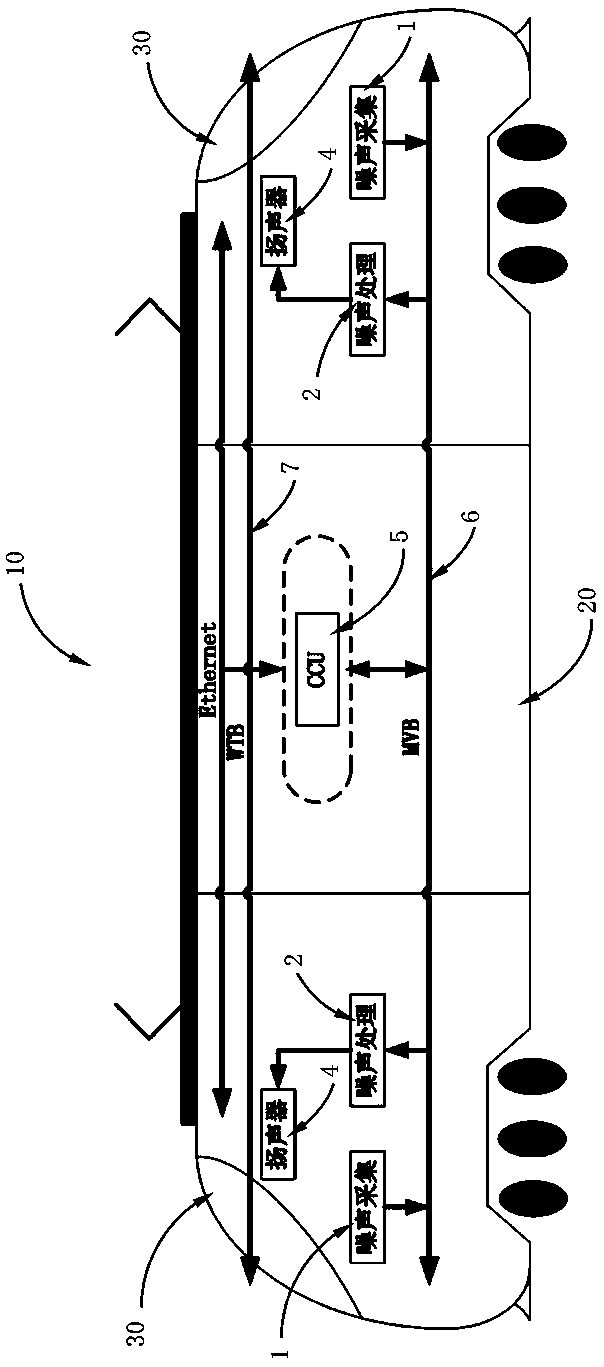

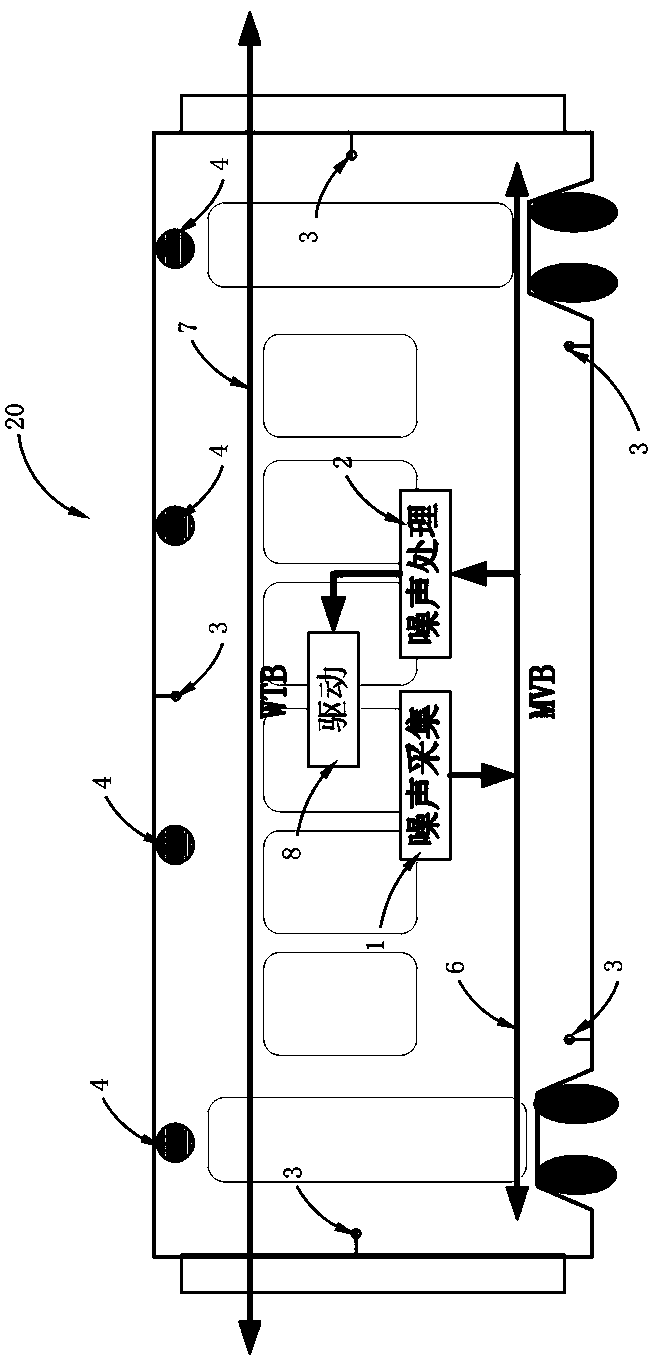

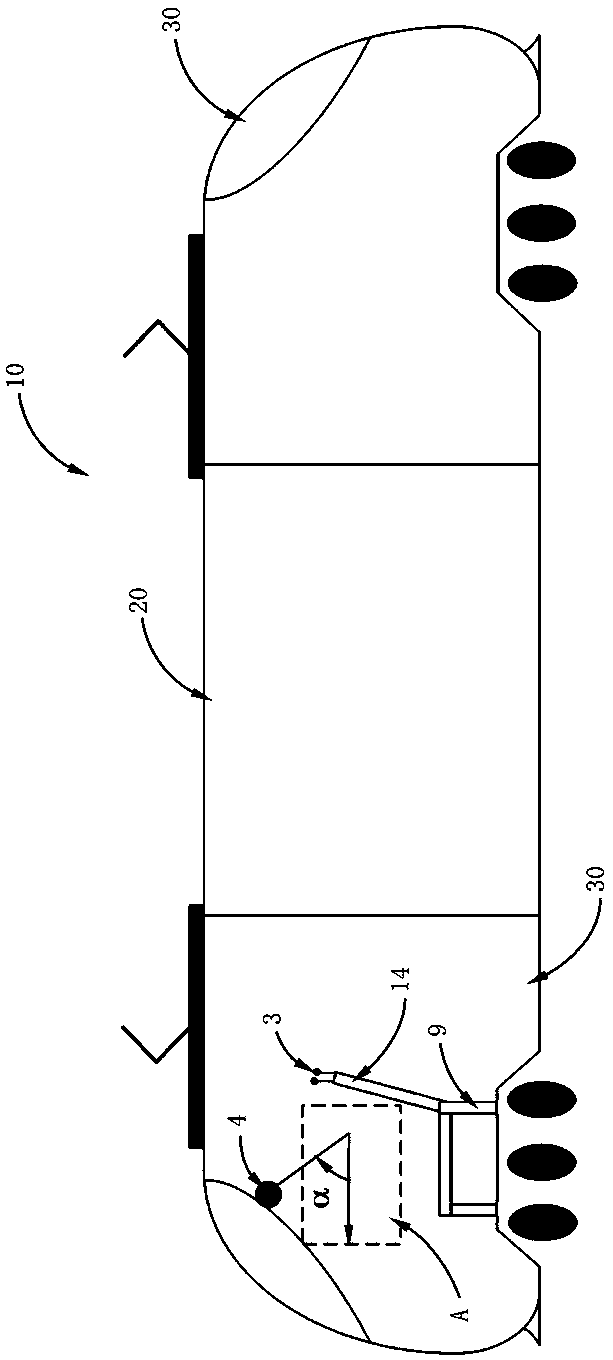

[0054] as attached figure 1 As shown, a specific embodiment of a train active noise reduction system includes: a noise collection unit 1 , a noise processing unit 2 , a microphone 3 , a loudspeaker 4 and an MVB bus 6 . Several microphones 3 are installed in the car body of the train 10 for collecting noise signals in the car body, and the microphone 3 further adopts a pickup microphone. The noise collection unit 1 transmits the noise signal collected by the microphone 3 to the noise processing unit 2 through the MVB bus 6 . The noise processing unit 2 analyzes and processes the collected noise signal, generates frequency and amplitude equal to the noise signal, and cancels the sound wave signal with the opposite phase, and controls the loudspeaker 4 installed in the body of the train 10 to generate reverse sound waves to reduce or Cancels the noise in the car body.

[0055] The system further includes a central control unit 5 and a WTB bus 7. The noise acquisition unit 1 tra...

specific Embodiment

[0062] A specific embodiment of a train active noise reduction method, comprising the following steps:

[0063] A) The noise collection unit 1 collects noise signals in the body of the train 10 through the microphone 3;

[0064] B) The noise collection unit 1 transmits the noise signal collected by the microphone 3 to the noise processing unit 2 through the MVB bus 6;

[0065] C) The noise processing unit 2 analyzes and processes the collected noise signal, generates a frequency and amplitude equal to the noise signal, and cancels the sound wave signal in the opposite phase, and controls the loudspeaker 4 installed in the train 10 body to generate a reverse sound wave to Reduce or cancel the noise in the vehicle body.

[0066] The train active noise reduction method also includes the following steps:

[0067] The noise acquisition unit 1 transmits the noise signal collected by the microphone 3 to the central control unit 5 through the MVB bus 6 , and then realizes train-leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com