Preparation method of composite cavity microfibers based on micro-fluidic technology

A microfluidic technology and microfiber technology, which is applied in the field of cavity composite microfiber preparation, can solve the problems of unstable cell adhesion, limited application, unfavorable sodium alginate, etc., and achieve attachment and growth, enhanced stability, Effect of promoting adhesion and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] A method for preparing composite cavity microfibers based on microfluidic technology. In the process of preparing cavity microfibers, a modified material that can promote cell adherent growth is introduced into the inner cavity of the microfibers, and the cavity is formed At the same time, the modified material is attached to the cavity to form a modified coating, which can promote the adhesion and culture of cells in the later stage.

[0076] The microfluidic chip is composed of upper and lower layers of chips, both of which are made of polydimethylsiloxane; the chip has at least three parallel channel inlets and one general outlet; the microfluidic technology-based compound The requirements for the preparation method of hollow microfibers are as follows:

[0077] Lay the microfluidic chip flat, submerge the outlet of the chip in the receiving liquid, connect the syringe to the inlet of the microfluidic chip, and use the syringe pump to push the syringe to form a multi...

Embodiment 2

[0110] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

[0111] The microfluidic chip has a three-channel structure; compared with the microfluidic chip with a four-channel structure, the microfluidic chip with a three-channel structure has three independent sample inlets and three independent channels, and the modified fluid and The inert fluids are mixed together and merged into a central fluid. The channels from inside to outside are the mixture of inert fluid and modified fluid (fluid 1), the sample fluid (fluid 2) and the sheath flow fluid (fluid 3).

[0112] And when the microfluidic chip is a three-channel structure, the sizes of the three channels from small to large are as follows: the channel size of the inert fluid and the cavity modification fluid mixture < the channel size of the sample fluid < the channel size of the sheath fluid; The channel size of the sample fluid is larger than the channel size ...

Embodiment 3

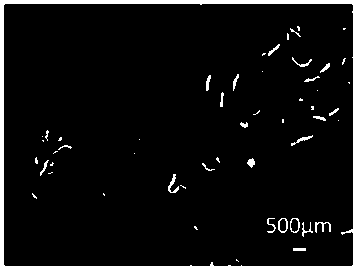

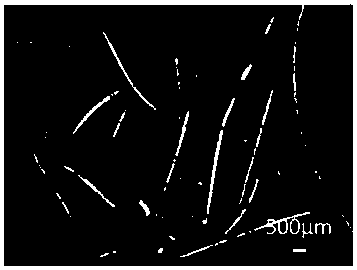

[0114] The chip used was a PDMS chip, which was sealed after oxygen plasma surface treatment, and then passed through perfluorinated liquid for 20 minutes to modify the surface of the channel. Vacuum dry the perfluorinated liquid and dry it in an oven at 80°C for later use. The chip structure diagram is as follows figure 1 shown.

[0115] 2% sodium alginate (viscosity 240mPa·s) containing 0.85% NaCl is used as sample fluid, 3% methylcellulose (viscosity 4000cP) is used as inert fluid, 5% chitosan ( Viscosity>400mPa s) as modified fluid, 1.1%CaCl containing 3% sucrose 2as a sheath fluid. The modification fluid can also be 5% chitosan and 3% methylcellulose mixed in different proportions to obtain methylcellulose solutions containing different chitosan concentrations (1%, 3%). Sterilize the methylcellulose at high temperature for half an hour, and then put it into a 4°C refrigerator to dissolve it for later use. Filter the sodium alginate solution with a 0.22 μm sterile fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com