High-speed rail sleeper beam robot automated production line

An automated production line and robot technology, which is applied in the direction of manipulators, other manufacturing equipment/tools, arc welding equipment, etc., can solve problems such as bad dust, and achieve the effect of saving costs, saving manpower, and improving the production environment in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

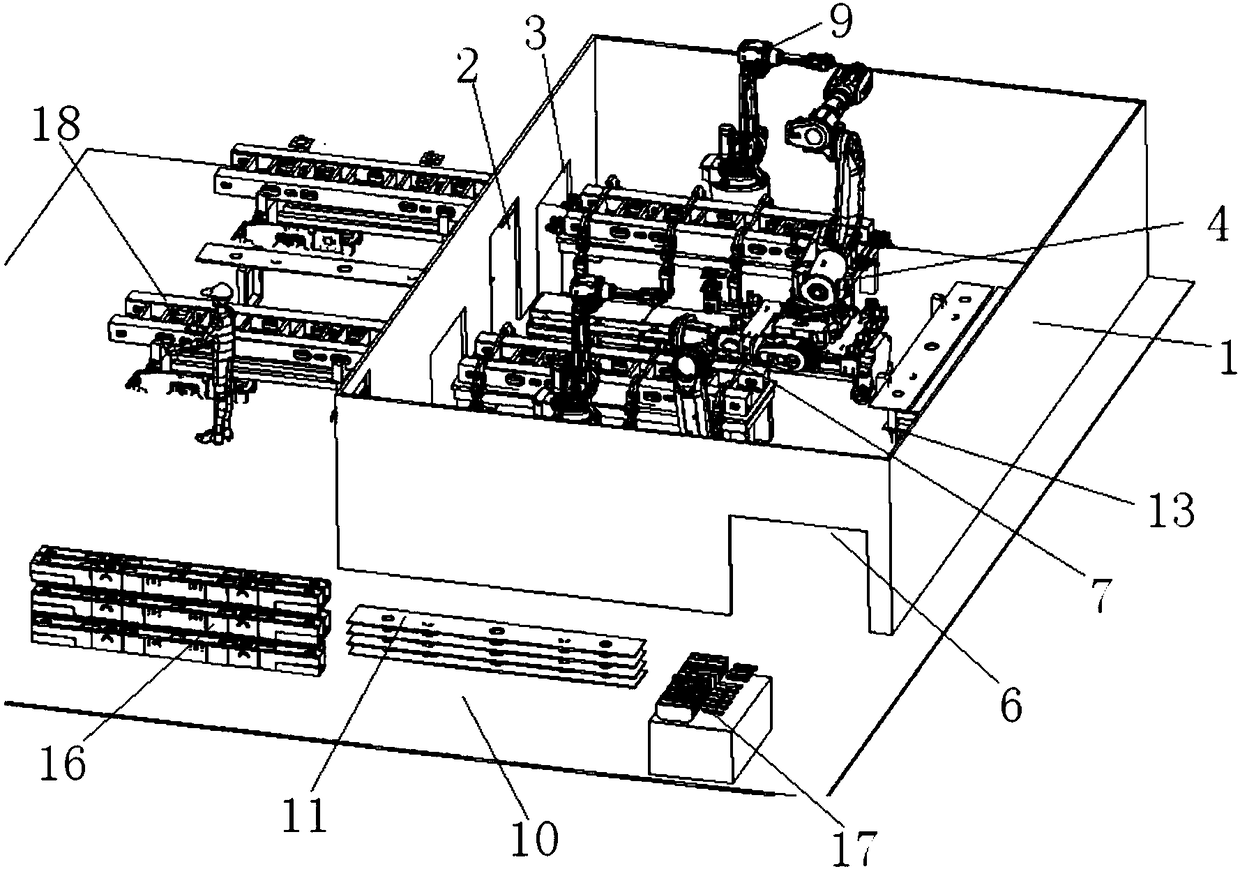

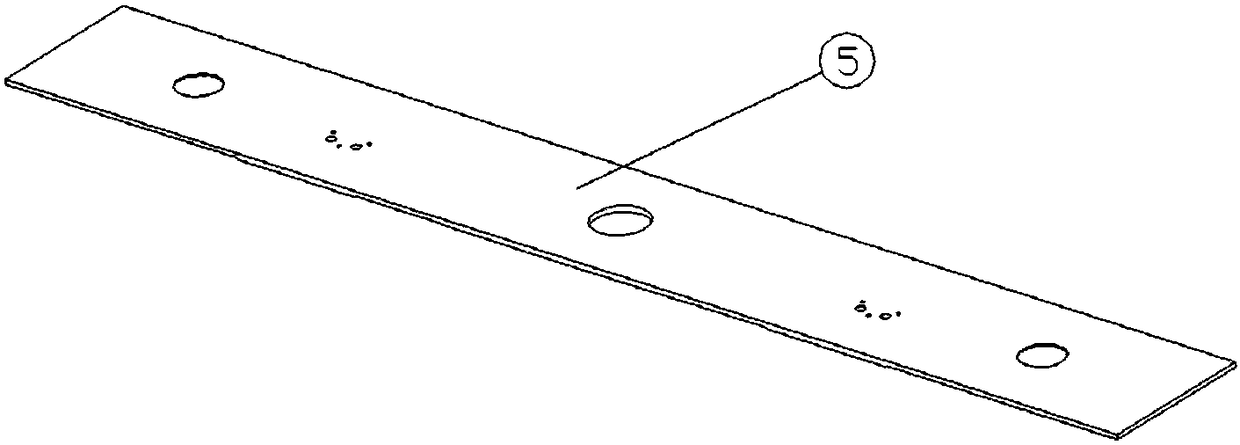

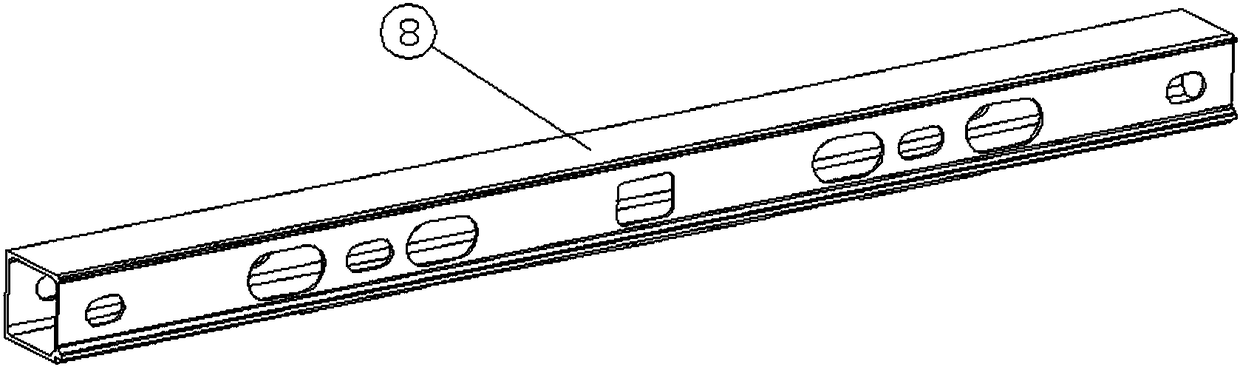

[0029] like Figure 1-5 Shown, a kind of automatic production line of high-speed railway corbel robot comprises closed work space 1, the first handling and polishing robot 4, the second handling and polishing robot 7 and automatic welding station 9, wherein said closed work space 1 is provided in the middle of one side There is a first material inlet 2, and the inner side of the closed working space 1, corresponding to the first material inlet 2, is provided with an upper part robot 4, which is used for positioning welding of the lower cover plate 5 and the side beam 8, and the upper part The front and rear sides of the robot 4 are respectively provided with platforms for placing large and small lower cover plates, and a second feed port 6 is provided on the side of the closed work space 1 adjacent to the first feed port 2, and the inside of the closed work space 1 , Corresponding to the second feed port 6, there is a grinding robot 7 for grinding the lower cover plate 5, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com