Asynchronous motor soft starter and predictive feedback control method based on same

An asynchronous motor, soft starter technology, applied in the direction of a single multi-phase induction motor starter, motor generator/starter, etc., can solve the problems of disorder, vibration, secondary impact, etc., to improve the disorder and control the speed sensitively , The effect of strong adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

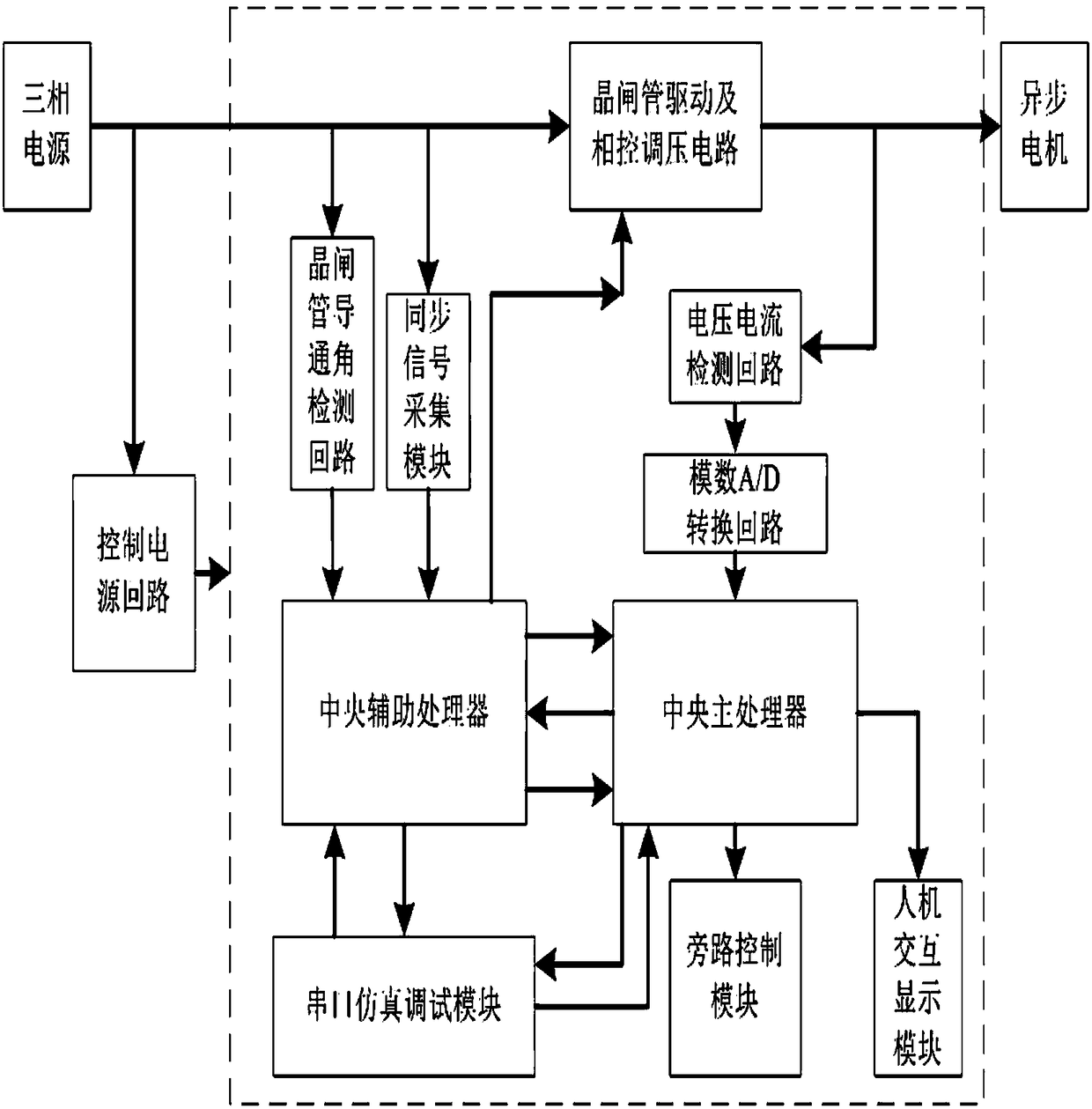

[0044] Such as Figure 1-Figure 3 A soft starter for an asynchronous motor, including a three-phase power supply interface, a control power supply circuit, a thyristor conduction angle detection circuit, a synchronous signal acquisition module, a central auxiliary processor, a serial port simulation debugging module, a thyristor drive and a phase control voltage regulation circuit, a voltage Current detection circuit, digital-analog A / D conversion circuit, central main processor, bypass control module, human-computer interaction display module and asynchronous motor interface;

[0045] The central auxiliary processor and the central main processor are connected through the SPI bus;

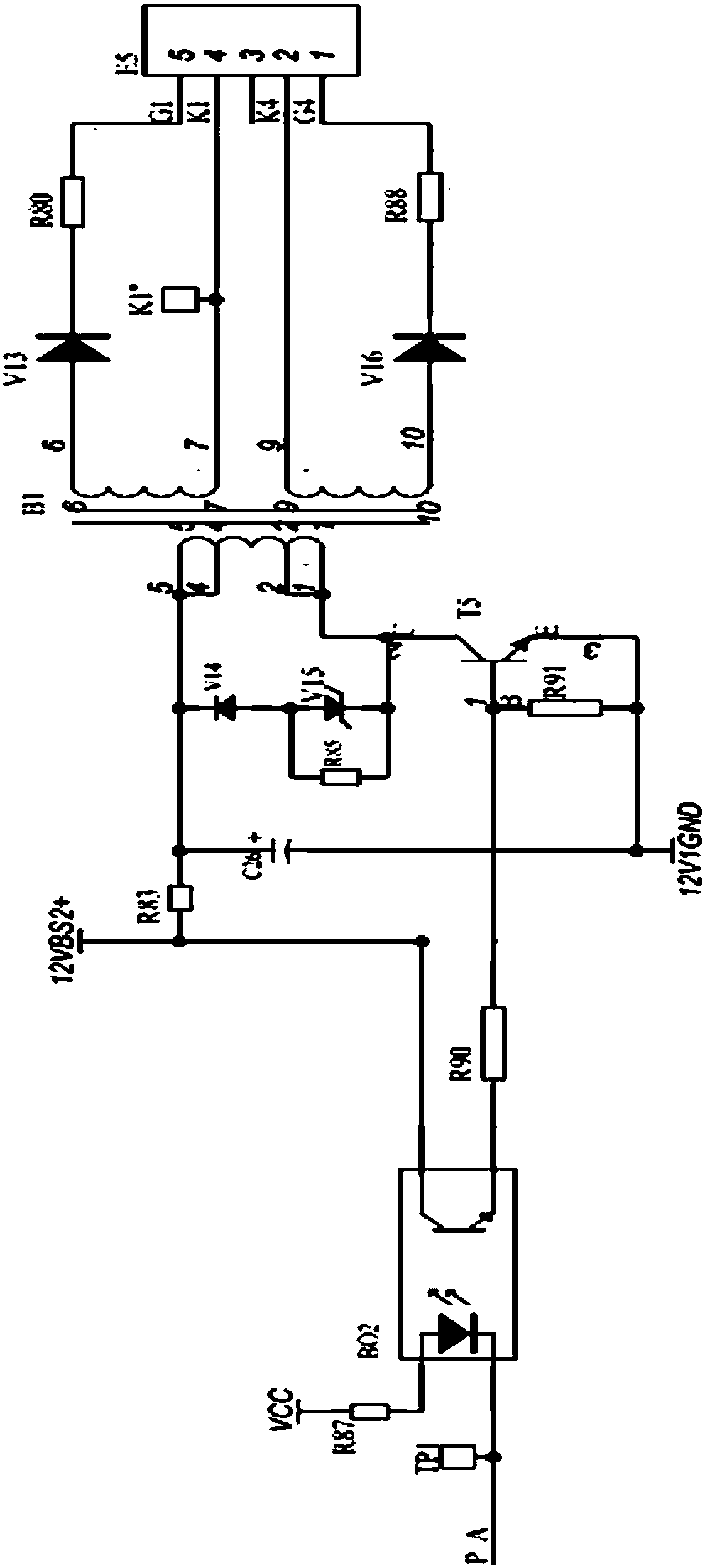

[0046] The three-phase power interface is connected to the input end of the thyristor drive and the phase-controlled voltage regulation circuit, and the output end of the thyristor drive and the phase-controlled voltage regulation circuit is connected to the interface of the asynchronous motor;

...

Embodiment 2

[0060] The predictive feedback control method of a soft starter for an asynchronous motor described in Embodiment 2 is implemented on the basis of the soft starter for an asynchronous motor described in Embodiment 1, and includes the following steps:

[0061] Step 1: Establish the asynchronous motor soft starter, connect the three-phase power supply interface with the three-phase electricity of the mains, and connect the asynchronous motor interface to the asynchronous motor;

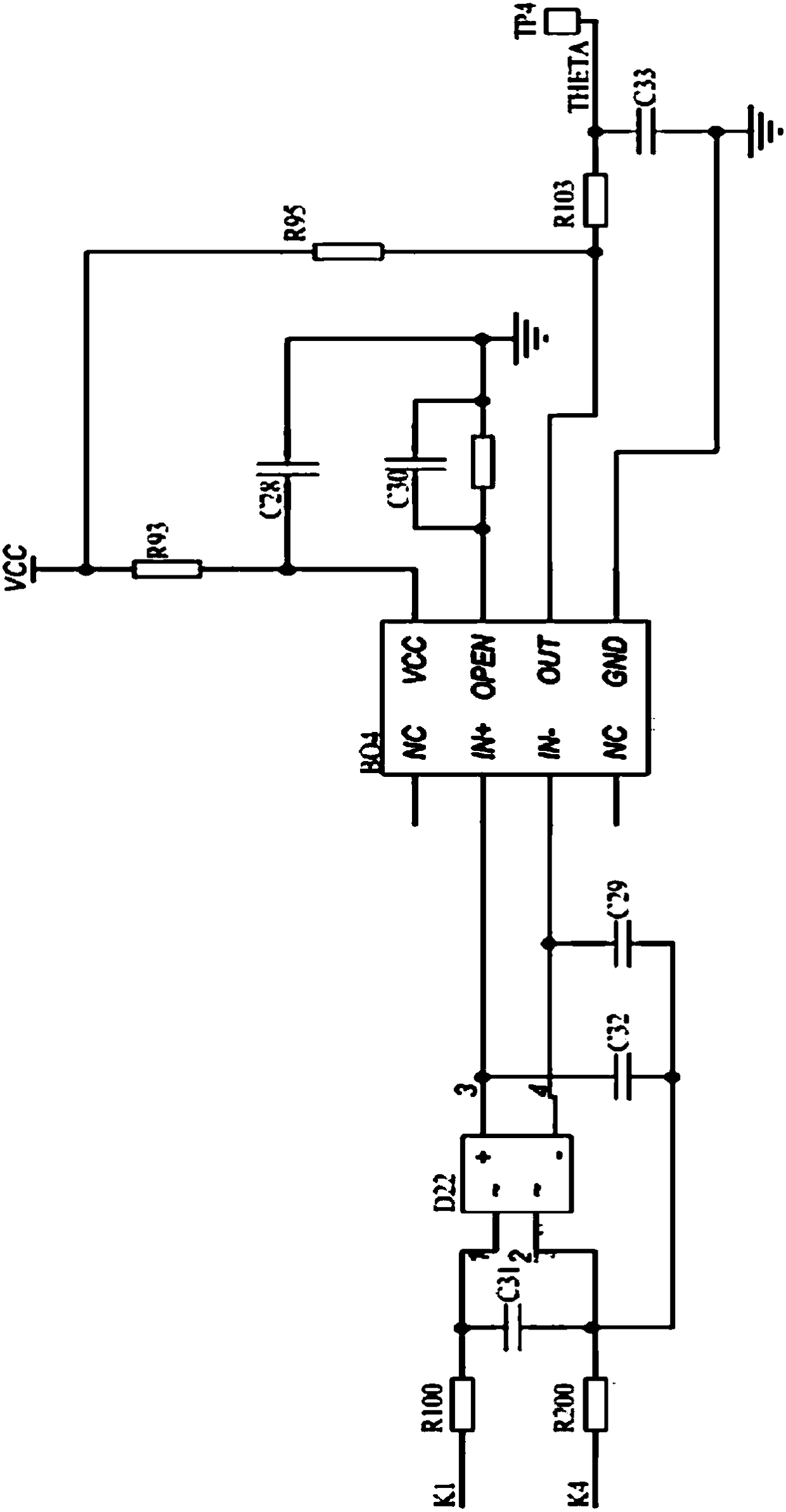

[0062] Step 2: The thyristor conduction angle detection circuit is used to detect the real-time data of the thyristor conduction angle in the thyristor drive and phase-controlled voltage regulation circuit, and generate real-time data of the thyristor conduction angle;

[0063] The synchronous signal acquisition module is used to detect the zero-crossing moment of the voltage of the three-phase power supply;

[0064] The voltage and current detection circuit collects the voltage signal and current signa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com