Preparation method of high-capacity and high-rate anode material suitable for power batteries

A negative electrode material and power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low gram capacity and poor rate performance, achieve high gram capacity, good processing performance, and improve overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

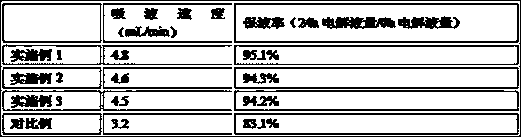

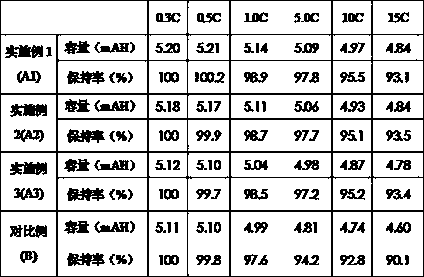

Examples

Embodiment 1

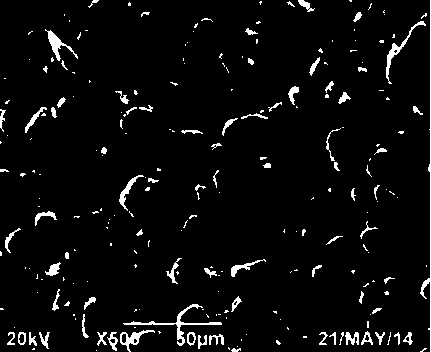

[0030] Step 1. preparation of ferric oxide hollow microspheres

[0031] Put 1.5g of sodium dodecylbenzenesulfonate into 150ml of ethylene glycol, stir well until a clear and transparent solution is formed, then add 5.5g of ferric chloride and 9.5g of sodium acetate and stir well, Pour the solution into a 250ml polytetrafluoroethylene container, put the polytetrafluoroethylene container into a high-pressure reactor, seal it, put it in an oven, let it react at 180°C for 12 hours, and separate the obtained black product with a magnet After that, wash with distilled water and absolute ethanol several times successively, and dry to obtain hollow microspheres of ferric oxide;

[0032] Step ② LiALO 2 Preparation of Composite Solution B

[0033] Add 5g of lithium metaaluminate and 5g of glucose to 100mL of twice distilled water, stir well to obtain LiALO 2 Composite solution B;

[0034] Step ③ Preparation of Solution C

[0035] Weigh 10g of titanium sheet and wash it with nitric ...

Embodiment 2

[0043] Step 1. preparation of ferric oxide hollow microspheres

[0044] Put 1g of sodium dodecylbenzenesulfonate into 100ml of ethylene glycol, stir well until a clear and transparent solution is formed, then add 5g of ferric chloride and 9g of sodium acetate and stir well, then pour the solution Put the polytetrafluoroethylene container into a 250 ml polytetrafluoroethylene container, put the polytetrafluoroethylene container into the high-pressure reactor and seal it, then put it in the oven, let it react at 180 ° C for 12 hours, and the black product obtained is separated by a magnet and used in turn. Wash with distilled water and absolute ethanol several times, and dry to obtain ferric oxide hollow microspheres;

[0045] Step ② LiALO 2 Preparation of Composite Solution B

[0046] Add 4g of lithium metaaluminate and 6g of glucose to 100mL of twice distilled water, stir well to obtain LiALO 2 Composite solution B;

[0047] Step ③ Preparation of Solution C

[0048] Weigh 1...

Embodiment 3

[0056] Step 1. preparation of ferric oxide hollow microspheres

[0057] Put 2g of sodium dodecylbenzenesulfonate into 200ml of ethylene glycol, stir well until a clear and transparent solution is formed, then add 6g of ferric chloride and 10g of sodium acetate and stir well, then pour the solution Put the polytetrafluoroethylene container into a 250 ml polytetrafluoroethylene container, put the polytetrafluoroethylene container into the high-pressure reactor and seal it, then put it in the oven, let it react at 180 ° C for 12 hours, and the black product obtained is separated by a magnet and used in turn. Wash with distilled water and absolute ethanol several times, and dry to obtain ferric oxide hollow microspheres;

[0058] Step ② LiALO 2 Preparation of Composite Solution B

[0059] Add 6g of lithium metaaluminate and 4g of glucose to 100mL of twice distilled water, stir well to obtain LiALO 2 Composite solution B;

[0060] Step ③ Preparation of Solution C

[0061] Weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com