Preparation and application of high-loading active substance electrode as well as electrode

A technology of active materials and electrode active materials, which is applied in the field of electrode materials for sodium ion batteries, can solve problems such as reducing battery performance, hindering sodium ion mass transfer, and reducing overall battery performance, so as to improve battery performance, strengthen diffusion, and promote diffusion. qualitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

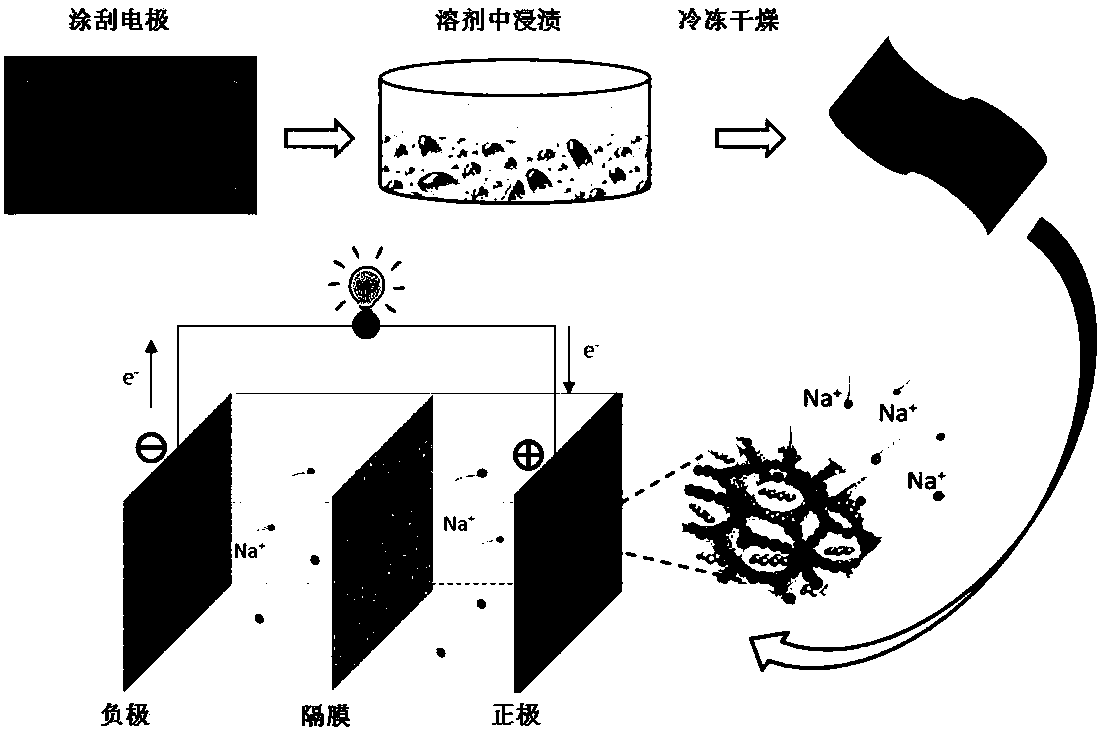

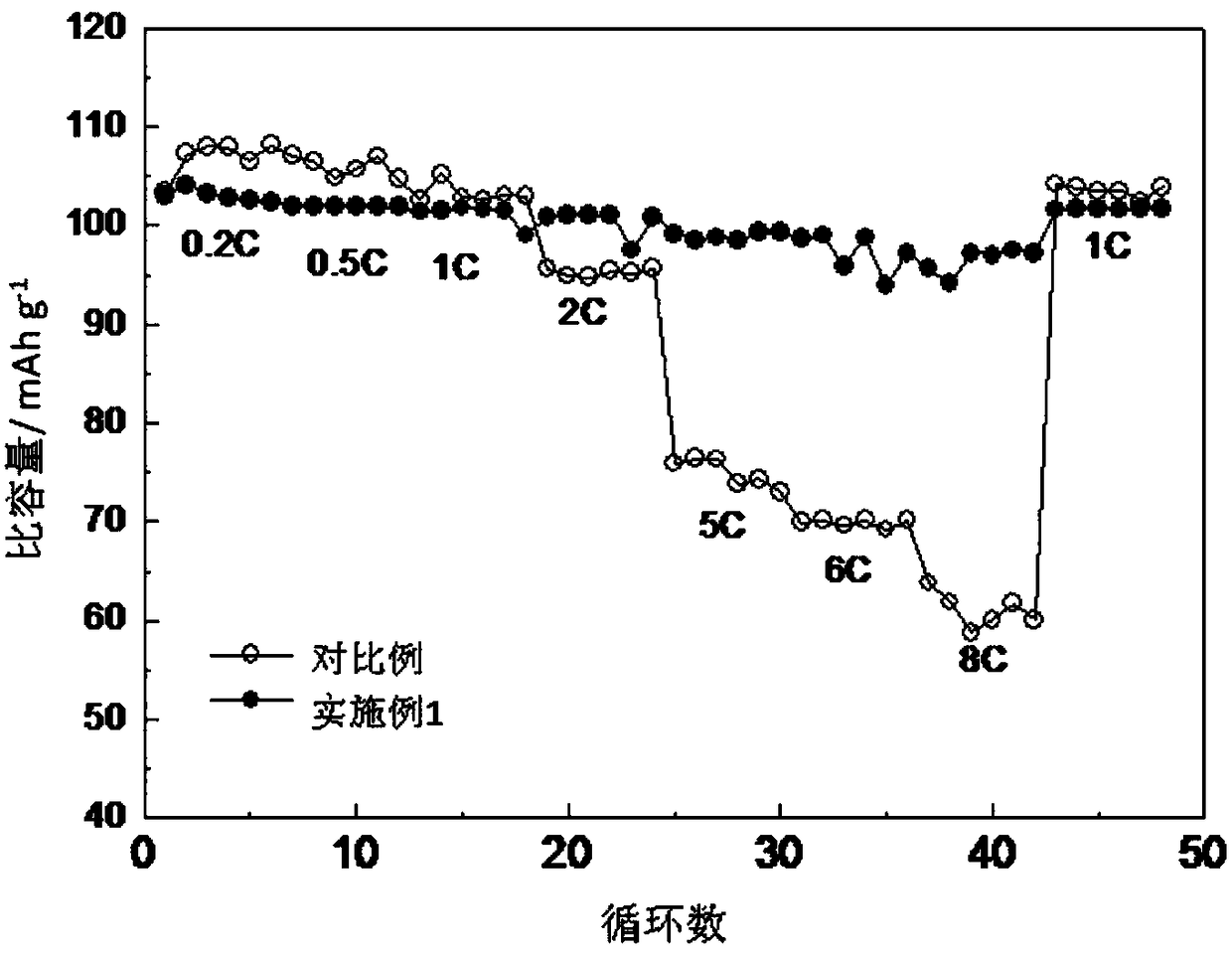

Embodiment 1

[0025] First, the electrode active material (the cathode material is sodium vanadium phosphate), the conductive agent (Super P) and the binder (PVDF-HFP) are mixed in a mass ratio of 70%: 20%: 10%, and N-methyl is used The pyrrolidone solvent is dissolved and stirred for 5 hours to prepare a uniformly mixed and viscous slurry; then the prepared viscous slurry is evenly coated on the aluminum foil with a coating device to obtain an electrode-collector integrated electrode . The thickness of the coated electrode is 700um. The prepared electrode-collector integrated electrode is immersed in water, and the immersion time is 30 minutes, which causes the coated electrode structure to expand and produce a fluffy porous structure. The integrated electrode immersed in the solvent was quickly placed in the freezer at -20 degrees for 2 hours, and then taken out, placed in a vacuum drying oven at -55 degrees for freeze drying, and maintained for 12 hours. The freeze-dried integrated elec...

Embodiment 2

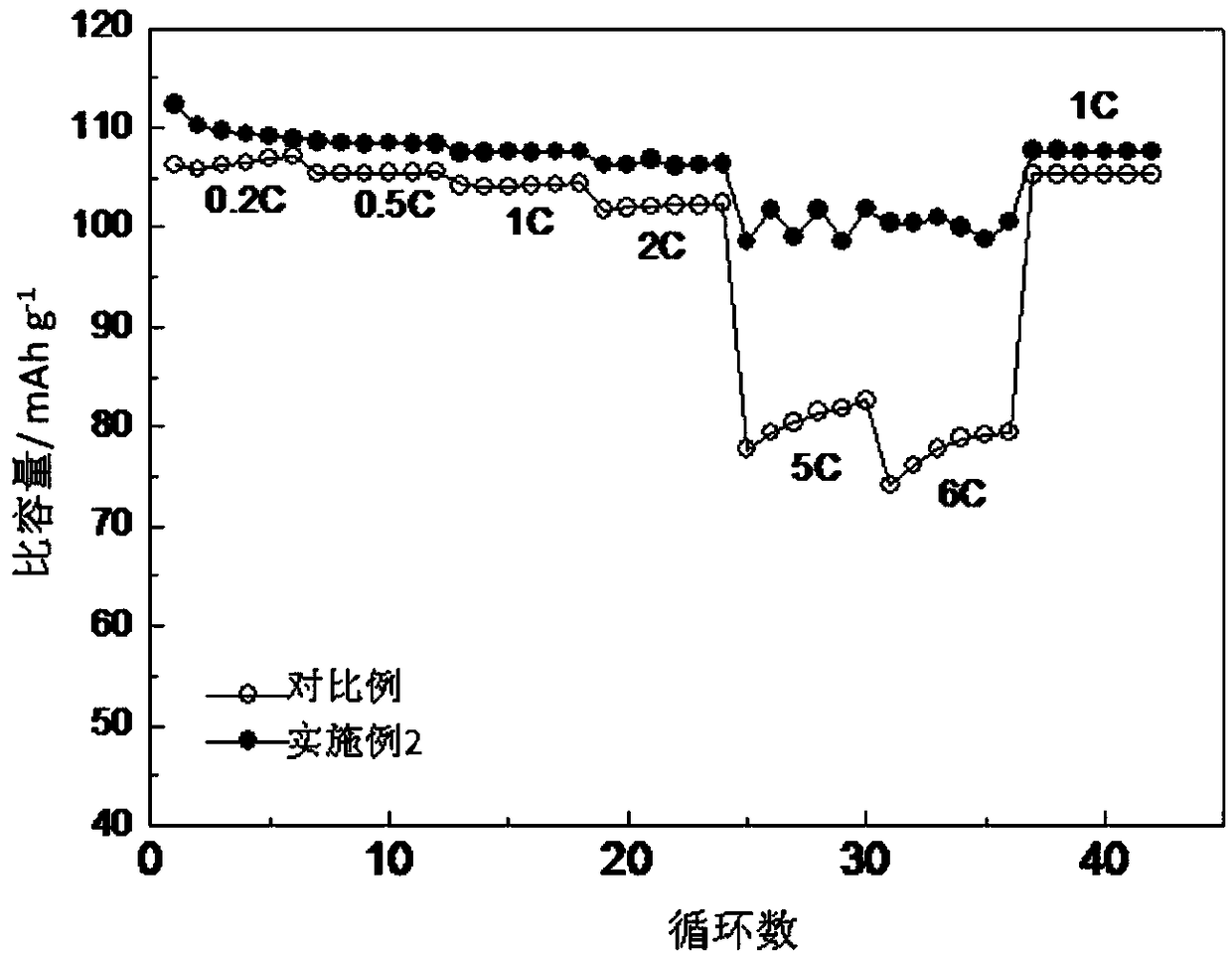

[0029] First, the electrode active material (the cathode material is sodium vanadium phosphate), the conductive agent (Super P) and the binder (PVDF-HFP) are mixed in a mass ratio of 70%: 20%: 10%, and N-methyl is used The pyrrolidone solvent is dissolved and stirred for 5 hours to prepare a uniformly mixed and viscous slurry; then the prepared viscous slurry is evenly coated on the aluminum foil with a coating device to obtain an electrode-collector integrated electrode . The thickness of the coated electrode is 1000um. The prepared electrode-current collector integrated electrode is immersed in water, and the immersion time is 30 minutes, so that the coated electrode structure is expanded and a fluffy porous structure is produced. The integrated electrode immersed in the solvent was quickly placed in the freezer at -20 degrees for 2 hours, and then taken out, placed in a vacuum drying oven at -55 degrees for freeze drying, and maintained for 12 hours. The freeze-dried integ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com