Preparation method of molybdenum disulfide and sulfur-doped carbon sphere composite electrode

A molybdenum disulfide, composite electrode technology, applied in the field of dye-sensitized solar cells, can solve the problems of high price and unsuitable for large-scale application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 The amount of precursor solution is 100 μL, and the MoS is prepared at 800°C for 10 minutes 2 / S-doped carbon sphere composite counter electrode

[0024] Fully disperse 50mg of carbon powder in 10mL of ethanol, add appropriate amount of MoCl 5 making MoCl 5 The concentration is 330mmol / L, and stir well. Then take 100 μL of the above precursor solution, evenly drop-coat it on a 3×5 cm graphite paper, and then dry it on a hot stage at 60°C for 10 min. Put the dried sample in a tube furnace, and take 1g of sulfur powder and place it at the end of the tube furnace near the air inlet, heat it to 800°C at a rate of 10°C / min in an Ar atmosphere, keep it warm for 10min, and then Cool down to room temperature naturally.

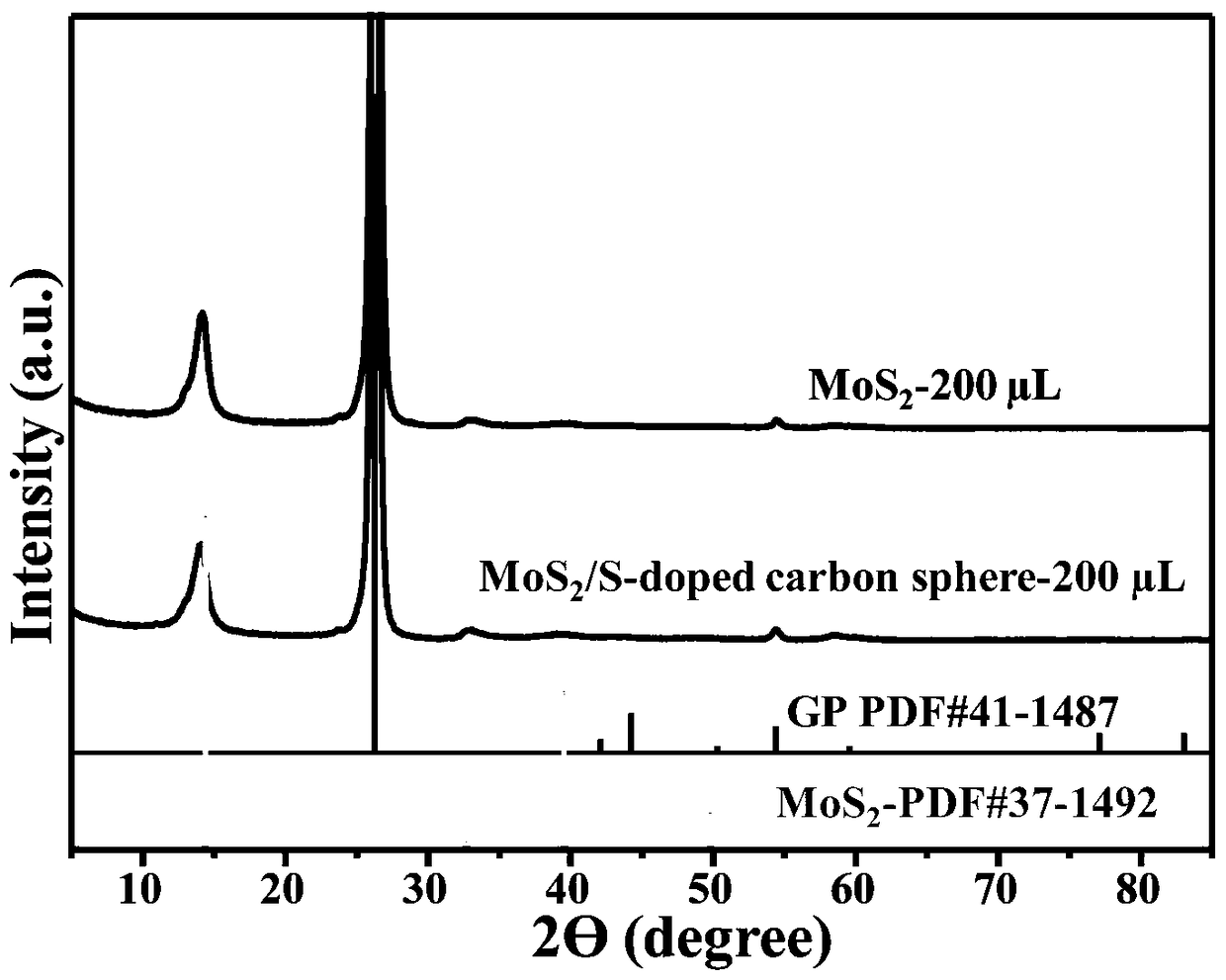

[0025] The XRD of the obtained samples is presented at figure 1 In , the diffraction peak at 14.38° corresponds to MoS 2 (002) crystal face, indicating that MoS was successfully prepared on graphite paper 2 . SEM images are presented at Figu...

Embodiment 2

[0032] Example 2 The amount of precursor solution is 200 μL, and the MoS is prepared at 800°C for 10 minutes 2 / S-doped carbon sphere composite counter electrode

[0033] Fully disperse 50mg of carbon powder in 10mL of ethanol, add appropriate amount of MoCl 5 , such that MoCl 5 The concentration is 330mmol / L, and stir well. Then take 200 μL of the above precursor solution, drop-coat it evenly on a 3 × 5 cm graphite paper, and then dry it on a hot stage at 60 °C for 10 min. Put the dried sample in a tube furnace, and take 1g of sulfur powder and place it at the end of the tube furnace near the air inlet, heat it to 800°C at a rate of 10°C / min in an Ar atmosphere, keep it warm for 10min, and then Cool down to room temperature naturally. figure 2 is the XRD pattern of the obtained sample.

Embodiment 3

[0034] Example 3 The dosage of the precursor solution is 100 μL, and the MoS is prepared by incubating at 800°C for 10, 30, and 60 minutes 2 / S-doped carbonsphere composite counter electrode

[0035] Fully disperse 50mg of carbon powder in 10mL of ethanol, add appropriate amount of MoCl 5 making MoCl 5 The concentration is 330mmol / L, and stir well. Then 100 μL of the above precursor solution was taken, and evenly drop-coated on three sets of 3 × 5 cm graphite paper, and then dried on a hot stage at 60 ° C for 10 min. Put the dried sample in a tube furnace, and take 1g of sulfur powder and place it at the end of the tube furnace near the air inlet, heat it up to 800 °C at a rate of 10 °C / min in an Ar atmosphere, and keep it warm for 10, 30, 60min, and then naturally cooled down to room temperature to obtain three groups of samples with different holding times. Figure 5 It is the SEM image of the obtained sample. It can be seen from the figure that the microscopic morpholog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com