Unidirectional moisture-transported fabric preparation method and unidirectional moisture-transported fabric prepared thereby

A technology for moisture-conducting fabrics and fabrics, applied in the field of textile fabrics, can solve the problems of unfavorable fabric hydrophilicity and water repellency, affecting the unidirectional moisture-conducting effect of fabrics, and unfavorable rapid evaporation of moisture, etc. Process needs, the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

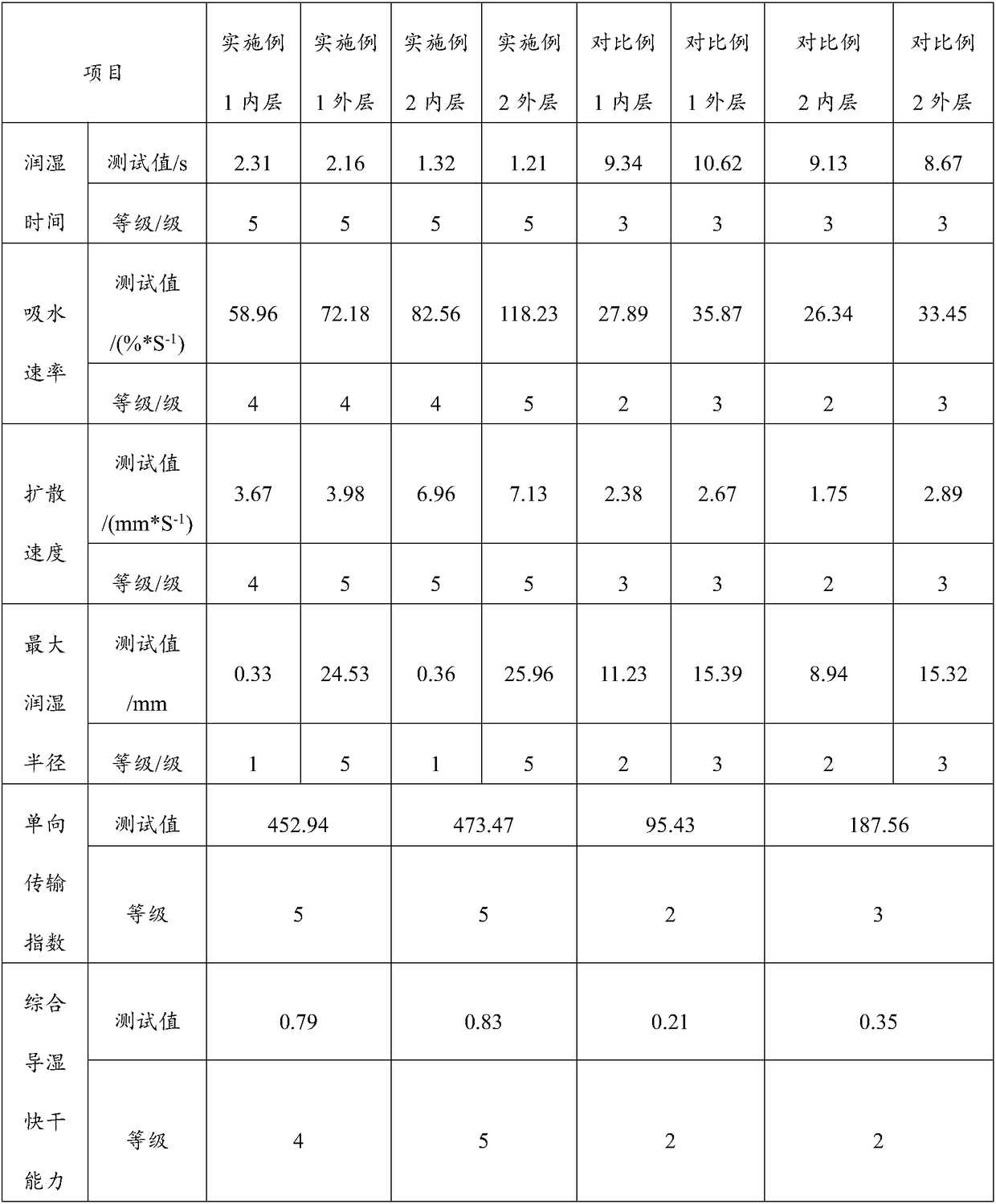

Examples

Embodiment 1

[0026] A kind of weft-knitted spacer fabric, gray cloth dry weight 296g / m 2 , the thickness of the fabric is 2.42mm, its transverse density is 98 / 5cm, and its longitudinal density is 84 / 5cm. It is woven from 150dtex / 48f low-elastic polyester filament, and its 2nd, 3rd, 5th, and 6th paths form spacer fabrics The upper and lower surface layers of the upper and lower layers, the 1st and 4th roads form the spacer layer used to connect the surface and the inner layer together, the spacer layer is woven with 100dtex polyester yarn with high bending stiffness, and the above weft-knitted spacer fabric is pressed Follow the steps below:

[0027] Step 1: Soak the cleaned fabric in sodium hydroxide lye with a temperature of 60°C and a concentration of 6wt% for 1 hour, take it out, and immerse it again in a finishing solution containing a hydrophilic finishing agent for 30 minutes. It is Nimate C901A, its concentration is 2g / liter of finishing solution, take out the fabric after impregna...

Embodiment 2

[0032] A warp-knitted spacer fabric, gray cloth dry weight 231g / m 2 , the thickness of the fabric is 3mm, and the surface layer of the fabric adopts 2 combs and adopts the method of 1 threading and 1 empty threading method to form a mesh. 5cm, the longitudinal density is 84 / 5cm, the surface and inner layer of the fabric are woven by 150dtex / 48f low-elastic polyester filament, and the spacer layer connecting the surface and inner layer is woven by 100dtex polyester filament with high bending stiffness. The above-mentioned warp-knitted spacer fabric is processed according to the following steps:

[0033] Step 1: Soak the cleaned fabric in sodium hydroxide lye with a temperature of 63°C and a concentration of 6wt% for 0.8h, take it out, and immerse it again in a finishing solution containing a hydrophilic finishing agent for 30min, and finish it hydrophilically The agent is Nimate C901A, the concentration of which is 2g / liter of finishing solution. After impregnation, the fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com