Colorful wear-resistant raw lacquer paint, and preparation method thereof

A raw lacquer coating and color technology, applied in the coating and other directions, can solve the problems of poor wear resistance, poor adhesion, inconvenient construction, etc., and achieve the effects of good wear resistance, good stain resistance, and not easy to pollute.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

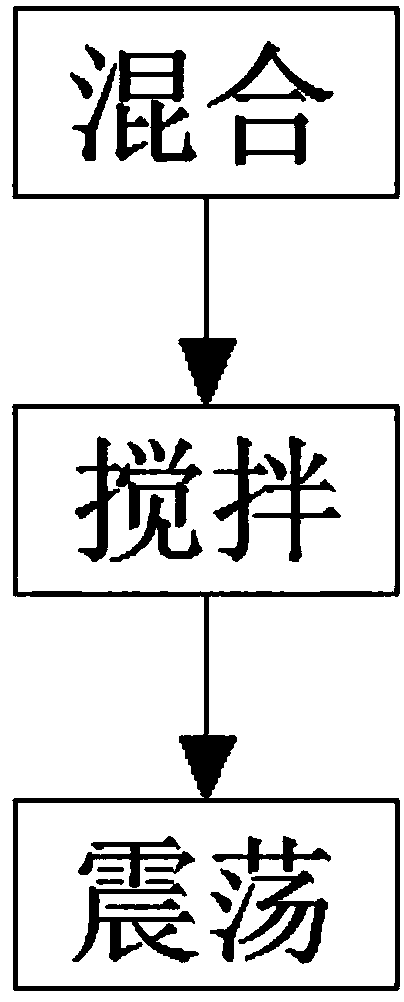

[0021] The preparation method of this colored wear-resistant raw lacquer coating comprises the steps:

[0022] S1: Mixing: Stir and mix raw lacquer, metal salt powder and modifier evenly;

[0023] S2: Stirring: Then add silica sol, surfactant and functional additives, stir evenly, the stirring speed is 175 rpm, and the stirring time is 2.5 hours;

[0024] S3: Oscillation: During the stirring process, ultrasonic wave is used for oscillation, the oscillation time is 2 hours, and finally the viscosity of the paint is adjusted.

[0025] In this embodiment, raw lacquer: 55 parts; metal salt powder: 1.5 parts, the metal salt powder is ferric chloride; modifier: 11 parts, the modifier is polyhydroxy acrylic resin; silica sol : 7 parts, the silica sol includes silica nanoparticles and acrylate binder; Surfactant: 3.5 parts, the surfactant consists of 2-perfluorooctyl ethyl acrylate and 3-methanol Acryloxypropyltrimethoxysilane; functional additives: 3.5 parts.

Embodiment 2

[0027] The preparation method of this colored wear-resistant raw lacquer coating comprises the steps:

[0028] S1: Mixing: Stir and mix raw lacquer, metal salt powder and modifier evenly;

[0029] S2: Stirring: Then add silica sol, surfactant and functional additives, stir evenly, the stirring speed is 150 rpm, and the stirring time is 2 hours;

[0030] S3: Oscillation: During the stirring process, ultrasonic vibration is used for 1.5 hours, and finally the viscosity of the paint is adjusted.

[0031] In this embodiment, raw lacquer: 50 parts; metal salt powder: 2 parts, the metal salt powder is ferric chloride; modifier: 10 parts, the modifier is polyhydroxy acrylic resin; silica sol : 8 parts, the silica sol includes silica nanoparticles and acrylate binder; Surfactant: 3 parts, the surfactant consists of 2-perfluorooctyl ethyl acrylate and 3-methanol Acryloyloxypropyltrimethoxysilane; functional additives: 5 parts.

Embodiment 3

[0033] The preparation method of this colored wear-resistant raw lacquer coating comprises the steps:

[0034] S1: Mixing: Stir and mix raw lacquer, metal salt powder and modifier evenly;

[0035] S2: Stirring: Then add silica sol, surfactant and functional additives, stir evenly, the stirring speed is 200 rpm, and the stirring time is 3 hours;

[0036] S3: Oscillation: During the stirring process, ultrasonic vibration is used for 2.5 hours, and finally the viscosity of the paint is adjusted.

[0037] In this embodiment, raw lacquer: 60 parts; metal salt powder: 1 part, the metal salt powder is ferric chloride; modifier: 12 parts, the modifier is polyhydroxy acrylic resin; silica sol : 6 parts, the silica sol includes silica nanoparticles and acrylate binder; Surfactant: 4 parts, the surfactant consists of 2-perfluorooctyl ethyl acrylate and 3-methanol Acryloxypropyltrimethoxysilane; functional additives: 2 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com