Isomerization catalyst, preparation and application

A catalyst, isomerization technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve problems affecting the reaction process, mass transfer problems of reactant molecules or product molecules, etc., and achieve high isomerization selection. Effects of sex and isomer yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

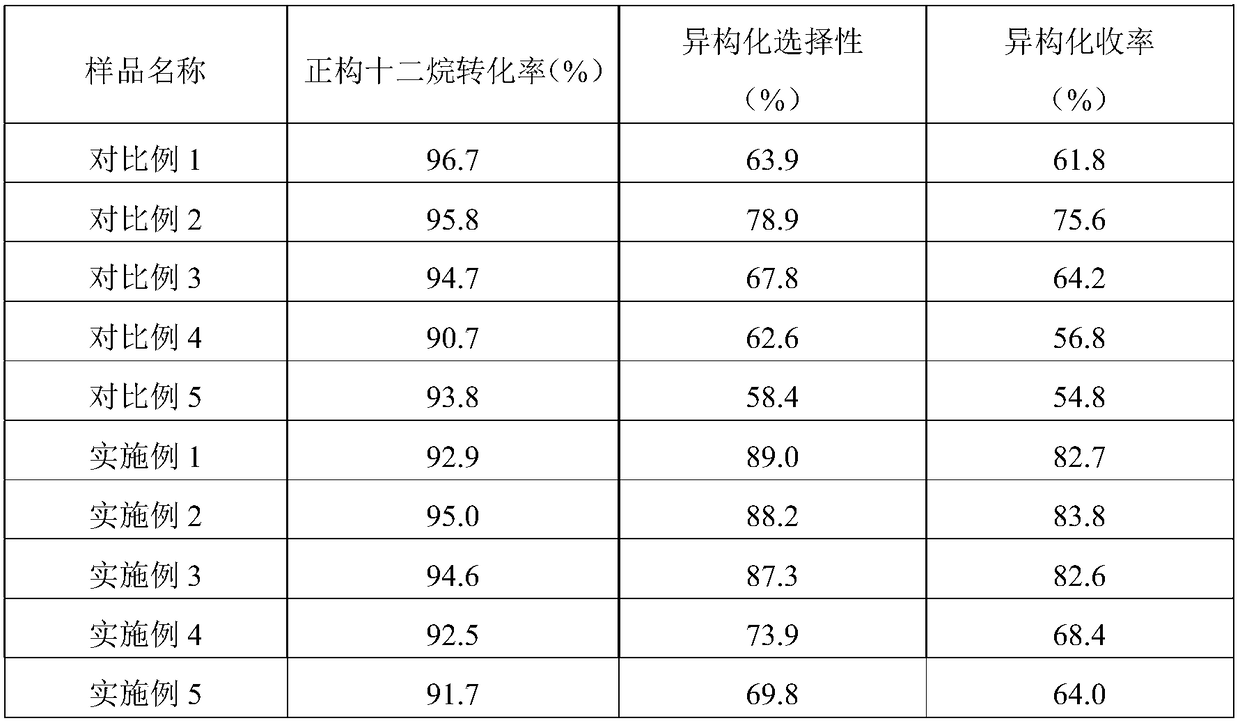

Examples

Embodiment 1

[0049] Take 5g of the ZSM-22 molecular sieve tablet from which the template agent has been completely removed in Comparative Example 1, crush it to 20-40 mesh, mix it with 10g of benzene, place it at 25°C for 6h, and dry the solid obtained after filtration at 120°C for 10min, then place it in Quartz tube, in N 2 Under atmosphere, treat at 500° C. for 4 hours and then cool to room temperature to obtain a modified ZSM-22 molecular sieve carrier. Wherein the content of carbon is 2.0wt.%, the micropore volume is 0.001cm 3 / g.

[0050] Take 2g of the above-mentioned ZSM-22 molecular sieve carrier, and use 2.0mL H 2 PtCl 6 The solution (containing Pt0.005g per mL) was impregnated, placed at room temperature for 12h, dried at 120°C for 2h, and then placed in a hydrogen atmosphere at 500°C for 4h to obtain the catalyst of the present invention with 0.5wt.% Pt.

[0051] Take 1.0 mL of the catalyst prepared above and put it in a stainless steel tube reactor. According to the reactio...

Embodiment 2

[0053] Take 5 g of the SAPO-11 molecular sieve tablet from which the template agent was completely removed in Comparative Example 2, crush it to 20-40 mesh, mix it with 10 g of n-heptane, place it at 25 ° C for 6 h, and dry the solid obtained after filtration at 120 ° C for 10 min, then placed in a quartz tube, in N 2 Under atmosphere, treat at 500° C. for 4 hours and then cool to room temperature to obtain the treated SAPO-11 molecular sieve carrier. Wherein the content of carbon is 1.8wt.%, the micropore volume is 0.01cm 3 / g.

[0054] Take 2g of the above-mentioned SAPO-11 molecular sieve carrier, and use 1.5mL H 2 PtCl 6 The solution (containing Pt0.0066g per mL) was subjected to saturated impregnation, placed at room temperature for 12h, then dried at 120°C for 2h, then placed in a hydrogen atmosphere at 500°C for 4h, to obtain the catalyst of the present invention containing 0.5wt.%Pt .

[0055] Take 1.0 mL of the above-prepared catalyst and put it in a stainless st...

Embodiment 3

[0057] Take 5g of the ZSM-23 molecular sieve tablet from which the template agent was completely removed in Comparative Example 3, crush it to 20-40 mesh, mix it with 10g of toluene, place it at 25°C for 6h, and dry the solid matter obtained after filtration at 120°C for 10min, then place In a quartz tube, in N 2 Under the atmosphere, treat at 500°C for 4 hours and then cool to room temperature to obtain a modified ZSM-23 molecular sieve, in which the carbon content is 0.5wt.%, and the micropore volume is 0.001cm 3 / g.

[0058] Take 2g of the above-mentioned ZSM-23 molecular sieve carrier, and use 2.0mL H 2 PtCl 6 The solution (containing Pt0.005g per mL) was subjected to saturated impregnation, placed at room temperature for 12h, then dried at 120°C for 2h, and then placed in a hydrogen atmosphere at 500°C for 4h to obtain the catalyst of the present invention with 0.5wt.% Pt.

[0059] Take 1.0 mL of the catalyst prepared above and put it in a stainless steel tube reactor....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com