Lithium-ion battery cathode material, preparation method thereof, and lithium-ion battery

A lithium-ion battery and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of no overheating protection, accidents, fires, etc., to achieve convenient operation, eliminate safety hazards, and improve energy Effects of Density and Safety of Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] According to the second aspect of the present invention, the present invention provides a method for preparing the above-mentioned lithium ion battery cathode material, which includes the following steps:

[0058] The heat-sensitive functional layer is coated on the surface of the positive electrode material particles by a sputtering method to obtain a lithium ion battery positive electrode material.

[0059] The method for preparing the positive electrode material of lithium ion battery provided by the present invention coats the thermosensitive functional layer on the surface of the positive electrode active material particles by sputtering, so that the thermistor functional layer coats the positive electrode active material particles uniformly without affecting the positive electrode The morphology of the active material particles.

[0060] In a preferred embodiment of the present invention, the preparation method of a lithium ion battery cathode material specifically inclu...

Embodiment 1

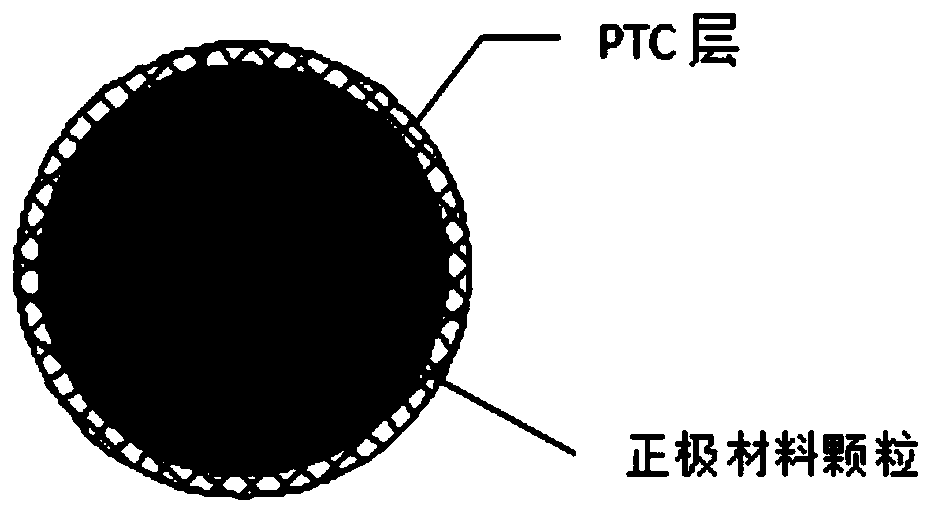

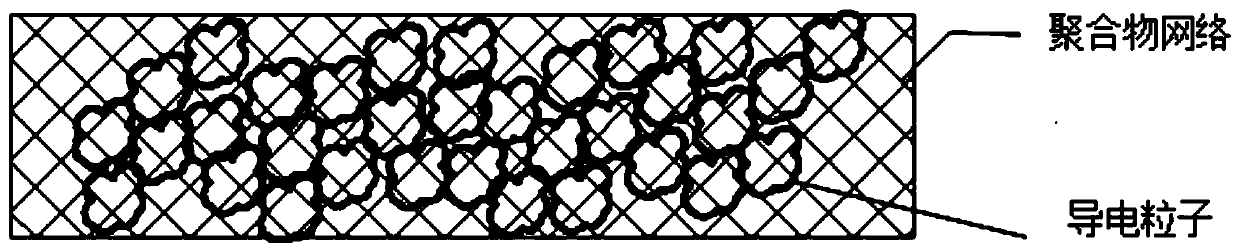

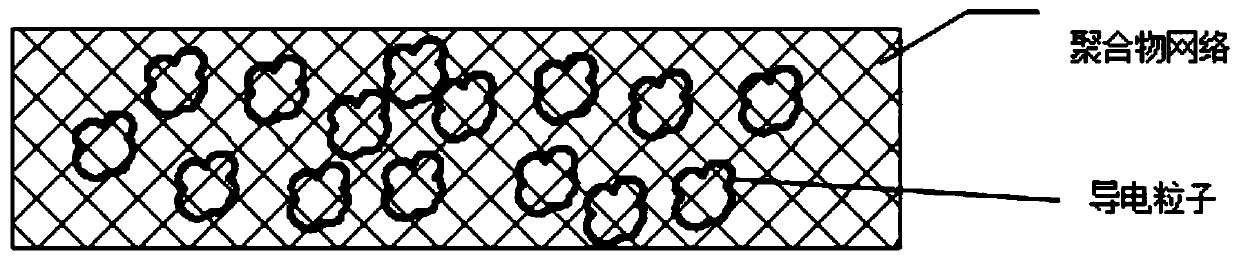

[0068] This embodiment provides a lithium ion battery cathode material, which includes a core formed by nickel cobalt lithium aluminate particles with a particle size of 100 μm and a thermistor functional layer with a thickness of 30 nm covering the surface of the core. The thermistor functions The layer is made of graphene and polypropylene with a particle diameter of 20 nm, wherein the volume ratio of graphene in the thermistor functional layer is 20%.

Embodiment 2

[0070] This embodiment provides a lithium ion battery cathode material, including a core formed by lithium nickel cobalt manganate particles with a particle size of 5 μm and a thermistor functional layer with a thickness of 5 nm covering the surface of the core. The thermistor functions The layer is made of carbon nanotubes with a particle diameter of 5 nm and polyethylene, wherein the volume ratio of the carbon nanotubes in the thermistor functional layer is 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com