Cable connectors and cable connection controls

A technology of cable connectors and controllers, which is applied to the parts, connections, coupling devices, etc. fire effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

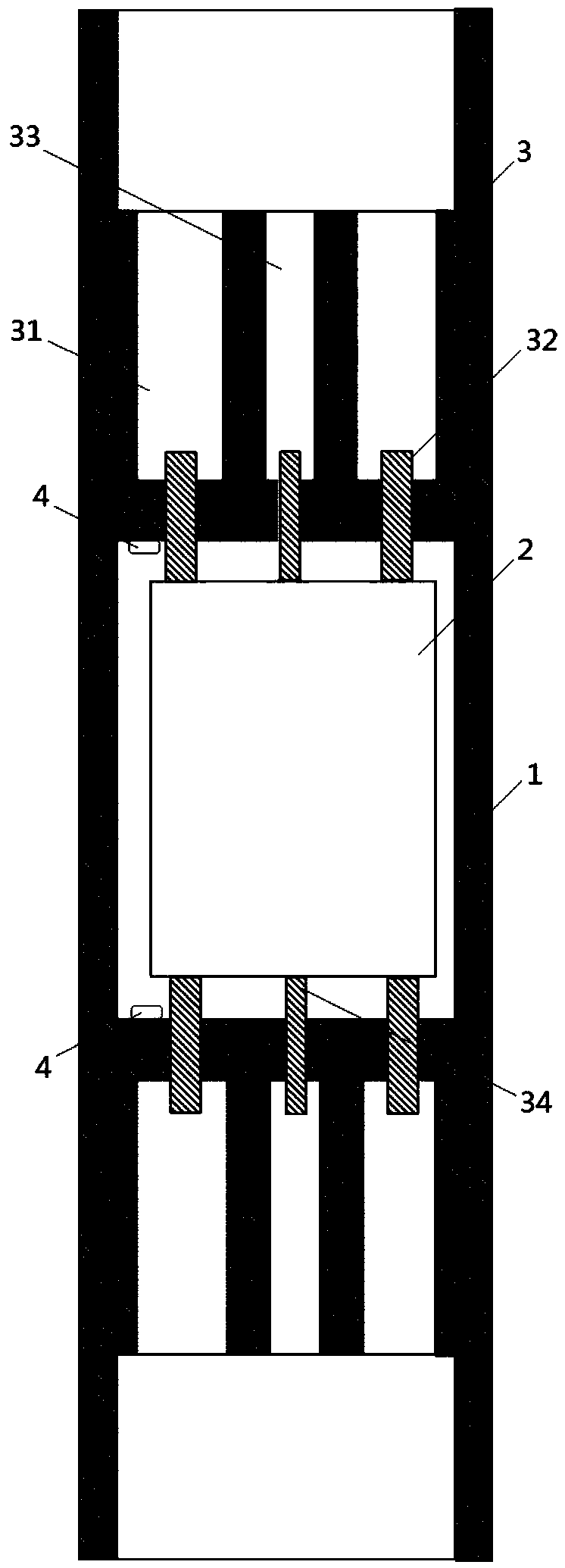

[0035] figure 1 A schematic structural diagram of the cable connector provided by this embodiment is shown. Such as figure 1 As shown, this embodiment provides a cable connector, including a hollow insulating shell 1 , a high voltage relay 2 disposed inside the insulating shell 1 , and a plug assembly 3 symmetrically connected to both ends of the high voltage relay 2 and the insulating shell 1 .

[0036] The two plug assemblies 3 are used to connect high-voltage cables (not shown), so that the two high-voltage cables communicate with the high-voltage relay 2 .

[0037] Both plug assemblies 3 are provided with a temperature sensor 4 for measuring the temperature of the plug assembly 3 . The temperature sensor 4 is arranged on the outside of the bottom wall where the plug assembly 3 is connected to the insulating shell 1 . The outer side of the bottom wall refers to the side of the bottom wall adjacent to the high voltage relay 2 .

[0038] A controller and a weak power sup...

Embodiment 2

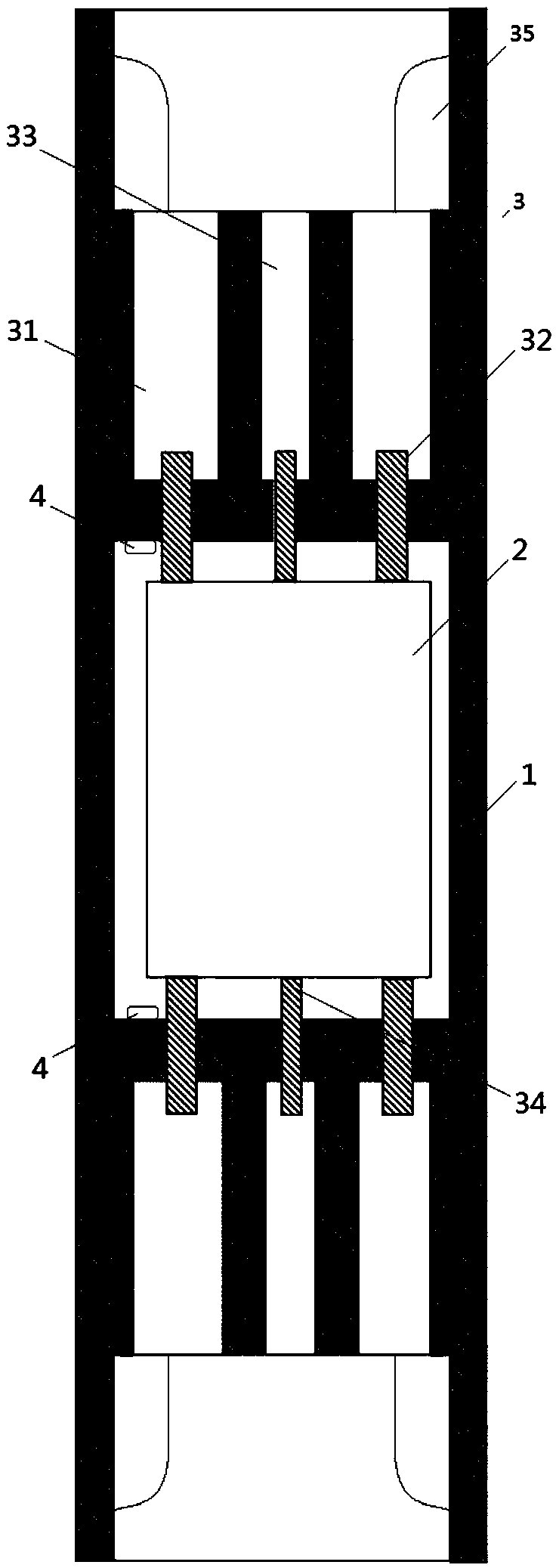

[0054] figure 2 A schematic structural diagram of the cable connector provided by this embodiment is shown. Such as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, one or more ribs 35 parallel to the axial direction of the plug assembly are provided on the inner wall of the plug assembly 3 for the connection between the plug assembly 3 and the high-voltage cable. Positioning to prevent misconnection of phase wires of high voltage cables.

[0055] The bottom end of the rib 35 is connected to the inner side of the bottom wall of the plug assembly 3 , and its height is greater than that of the phase line connection hole 31 and the neutral line connection hole 33 , but smaller than that of the plug assembly. The cross-section of the rib 35 is an arc or an irregular curve.

Embodiment 3

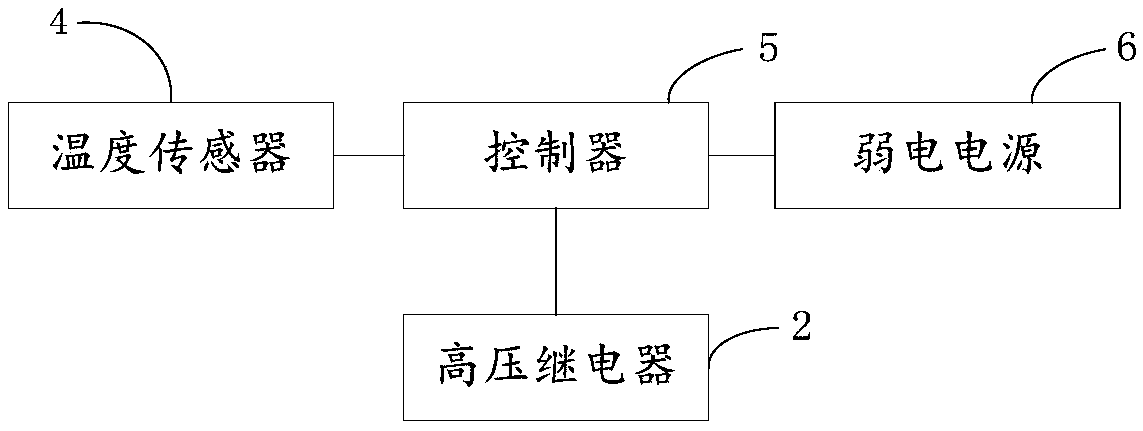

[0057] This embodiment provides a cable connection control device applied to the cable connector in the first or second embodiment above, image 3 A structural block diagram of the cable connection control device provided by this embodiment is shown. Such as image 3 As shown, the device includes a controller 5 arranged inside the insulating shell of the cable connector, a temperature sensor 4 and a high-voltage relay 3 connected to the controller 5 , and a weak power supply 6 for powering the controller 5 .

[0058] The high-voltage relay 2 is used to connect with the high-voltage cable through the plug assembly connected at both ends of the high-voltage relay, and control the connection and disconnection of the two high-voltage cables.

[0059] The temperature sensor 4 includes two temperature sensors connected to the two plug assemblies for measuring the temperature of the plug assemblies connected to both ends of the high voltage relay.

[0060] The controller 5 is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com