O2 configured lithium battery positive electrode material and preparation method thereof

A cathode material and lithium-ion battery technology, which is applied in the field of lithium-ion battery materials and electrochemistry, can solve the problems of electric vehicles not being widely used, the specific energy density of batteries is limited, and the problem of not being able to be better solved, and achieve uniform particle size. Small, simple steps, high tap density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

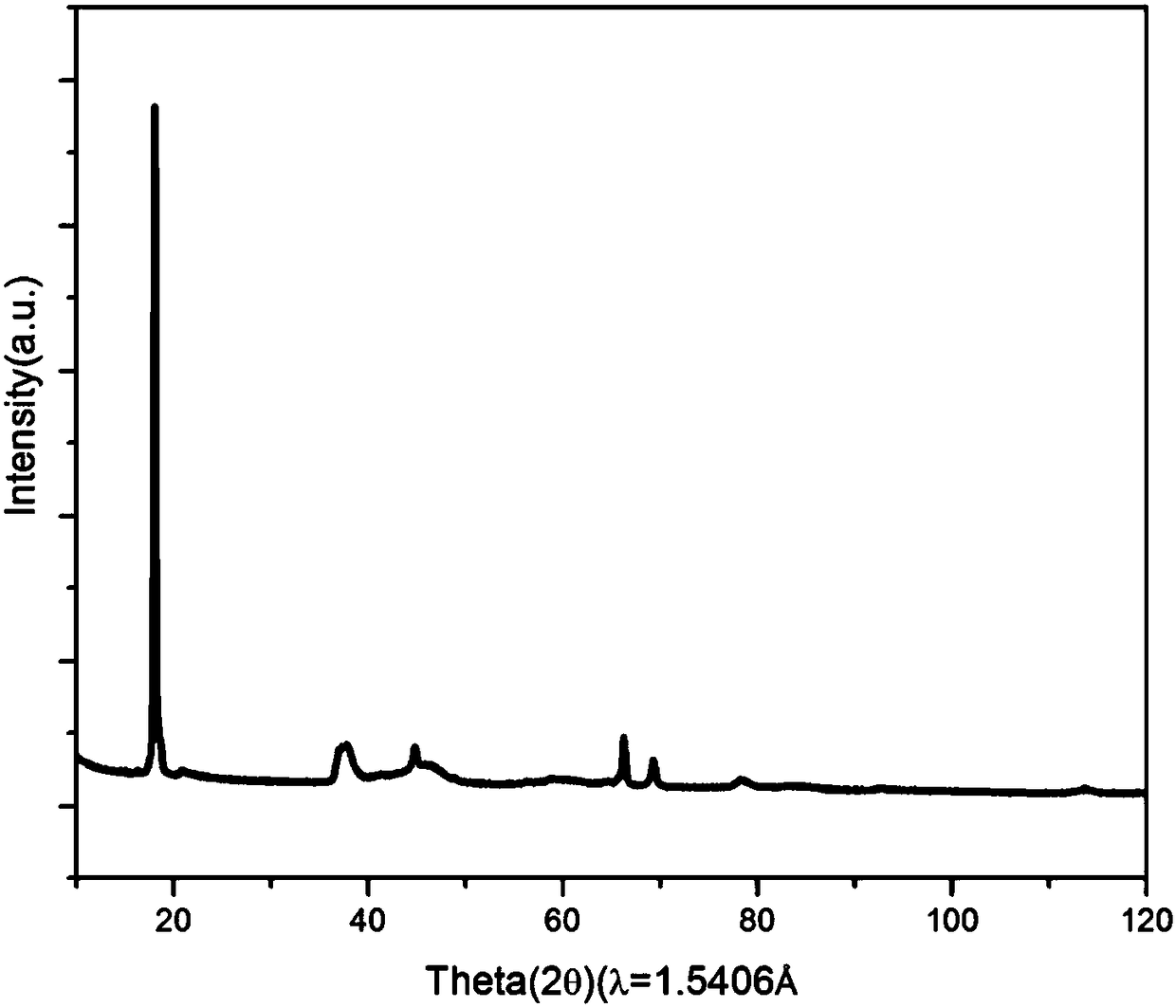

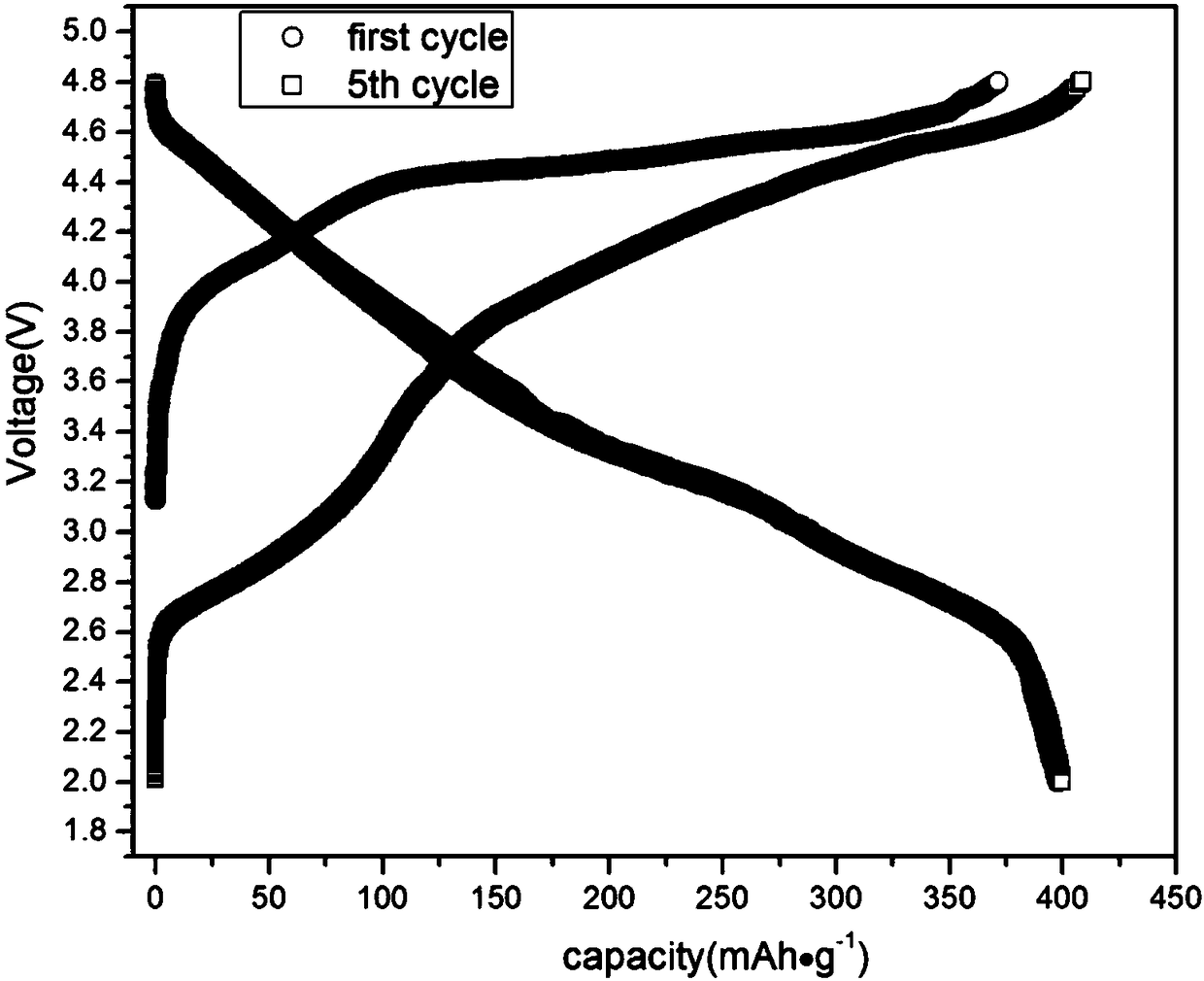

[0041] Embodiment 1, sol-gel synthesis O2 configuration ternary lithium-rich material Li[Li 0.2 mn 0.54 co 0.13 Ni 0.13 ]O 2

[0042] Dissolve 0.61g of lithium acetate, 3.4g of sodium acetate, 0.97g of nickel acetate, 3.97g of manganese acetate, 0.97g of cobalt acetate, 16.811g of citric acid and 7.4484g of ethylene glycol in 350mL of deionized water, stir and mix well. Put it in a pear-shaped bottle, and then rotate it in a rotary evaporator, the temperature is set at 80° C., and the rotation speed is 55 rpm. After steaming into a gel, place it in a vacuum oven at 150°C for more than 5 hours. Take out the dried gel, grind it, and place it in a tube furnace for 4 hours at 450°C for pre-calcination, followed by calcination at 800°C for 8 hours to obtain the sodium-containing precursor product——Na 0.833 [Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 .

[0043] The sodium-containing precursor was mixed with 2 times the molar amount of molten salt LiNO 3 , LiCl(LiNO 3 : LiCl=0...

Embodiment 2

[0046] Example 2, O2 configuration binary lithium-rich material Li[Li[Li] synthesized by co-precipitation method 0.25 mn 0.498 co 0.252 ]O 2

[0047] Take 0.039mol CoSO 4 ·6H 2 O, 0.081mol MnSO 4 ·H 2 O was dissolved in 60mL of deionized water and stirred evenly to form a salt solution, and then 0.132mol of Na 2 CO 3 Mix with 2mL ammonia solution whose concentration is 18.4mol / L to make 60mL alkali solution. Use a peristaltic pump to drop lye and salt solution into the deionized water at the same time, keep the pH between 7.5-8.5, and heat it in a water bath at a temperature of 60° C., while stirring continuously, and the stirring speed is 500 rpm.

[0048] After the dropwise addition, the obtained suspension was left to age for more than 12 hours, then filtered with a Buchner funnel, and washed with deionized water for more than 3 times. The precipitate obtained by filtration is dried in a vacuum oven at 80°C for more than 8 hours, and then ground to obtain the prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com