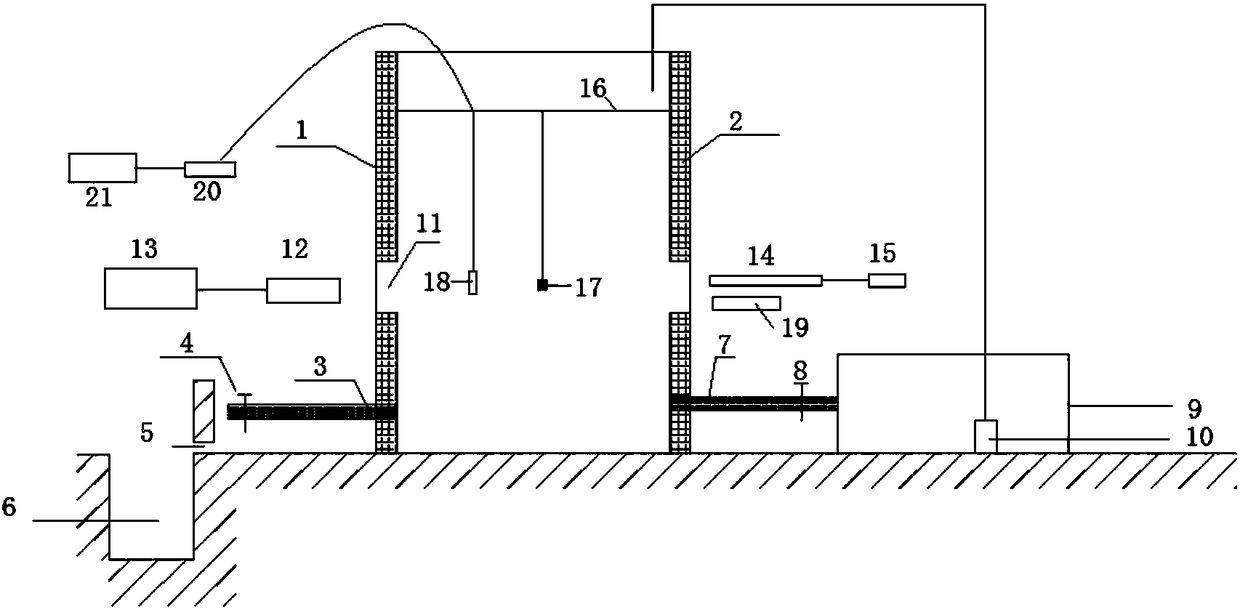

Method for testing strength of explosive for simulated underwater explosion test

A technology of underwater explosion and testing methods, which is applied in the direction of fuel oil testing, measuring devices, material inspection products, etc., can solve problems such as large errors and inaccurate bubble radii, and achieve the effects of reducing test costs, sufficient content, and multiple research angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

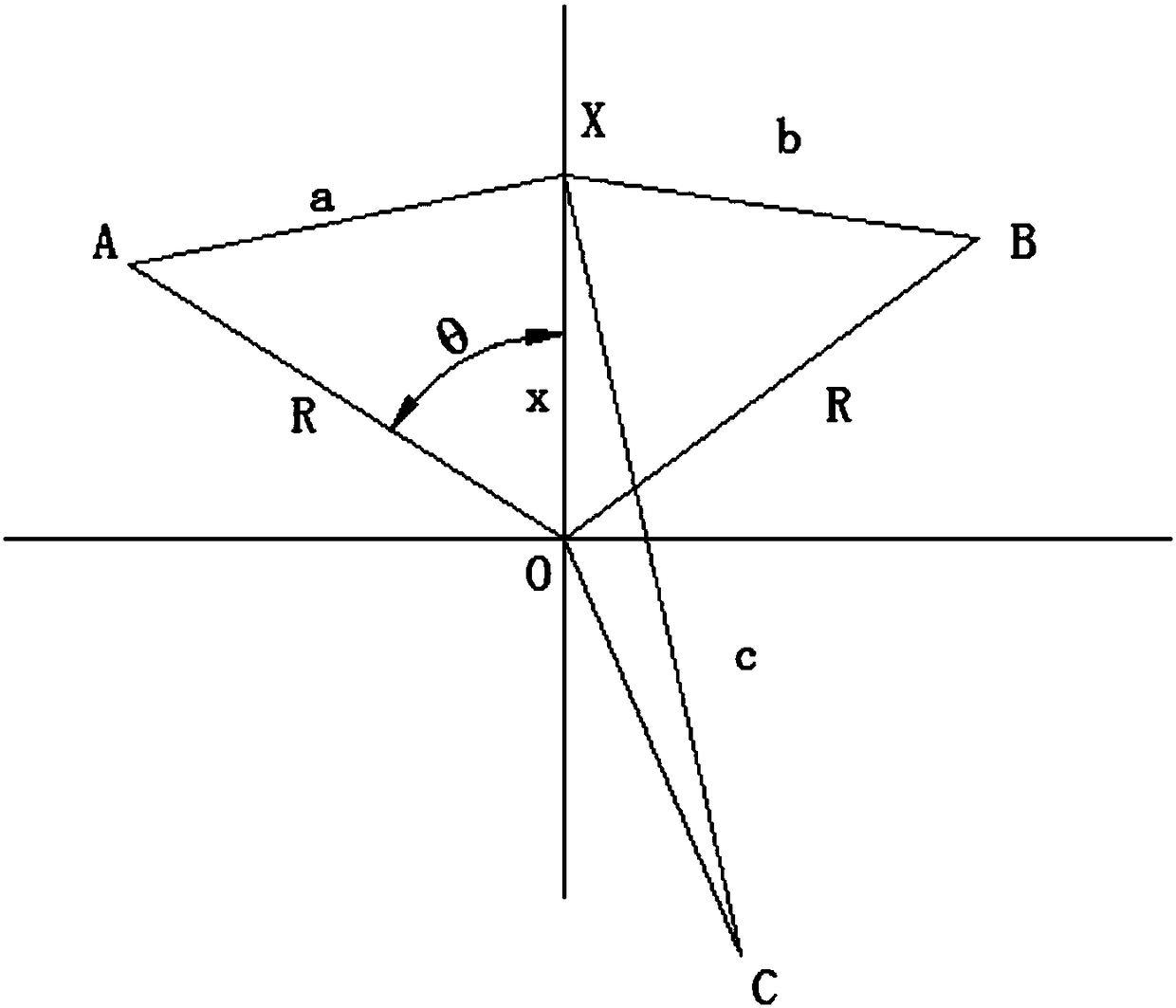

[0054] It is known that R=1m, θ=45°, measure a=0.850m, b=1.334m

[0055] Calculated to get X 1 =1.179m, X 2 =0.235m, X 3 =1.179m, X 4 =0.661m, so X=1.179m.

Embodiment 2

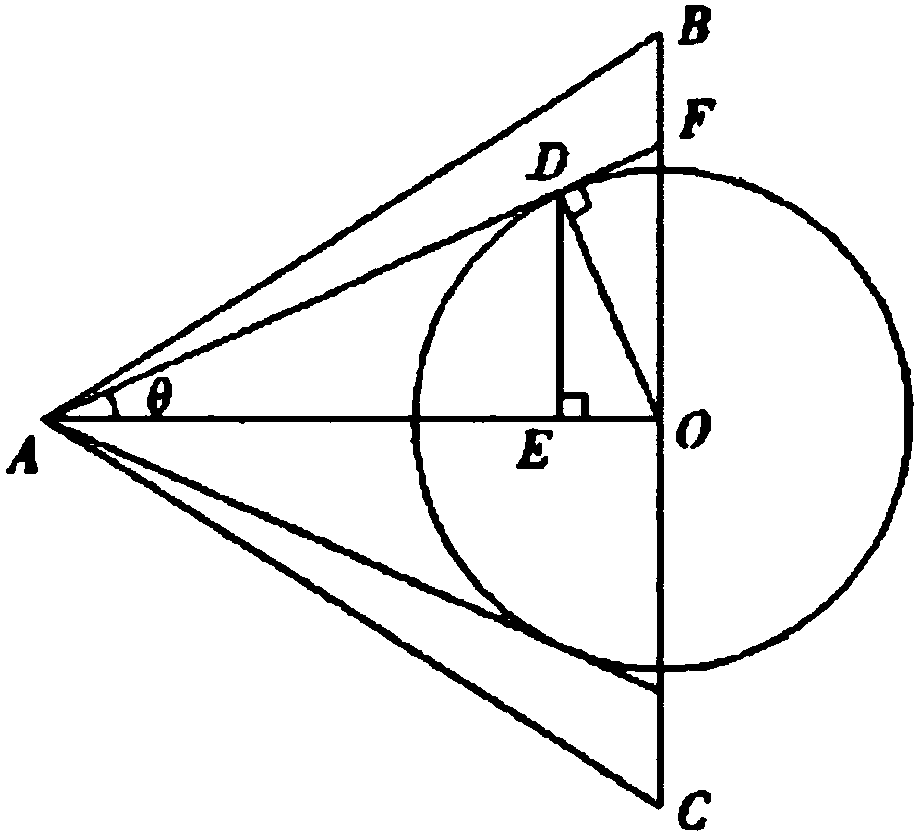

[0057] It is known that m1=1, m2=1.49, m3=1.33, measure h 1 = 0.200m, h 2 = 0.100m, h 3 = 1.025m, and the radius L of the picture taken of the air bubbles = 0.347m.

[0058] Calculation can get sinθ1=0.3285, R=0.300m, figure 2 The radius calculated by the method is 0.336m, and it is found by comparison that figure 2 The method has a margin of error of 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com