Video identification-based charge level diagnosis and self-adaptive control device and method for sintering machine

A self-adaptive control and video recognition technology, applied in the field of sintering, can solve the problems of poor air permeability, poor air permeability, over-melted layer and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

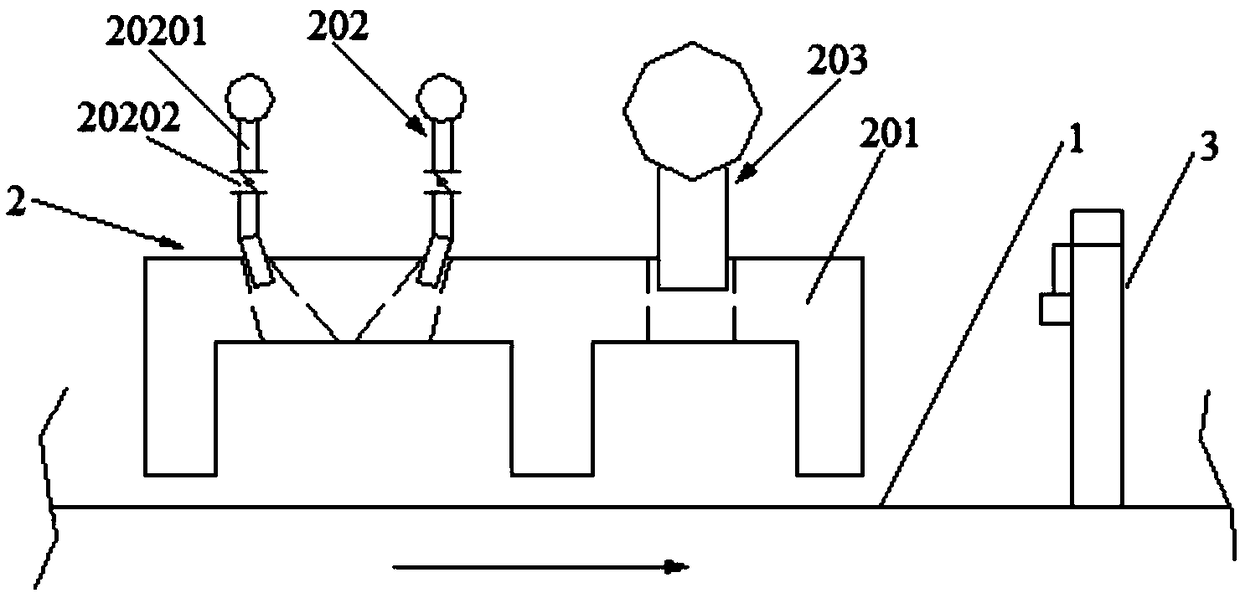

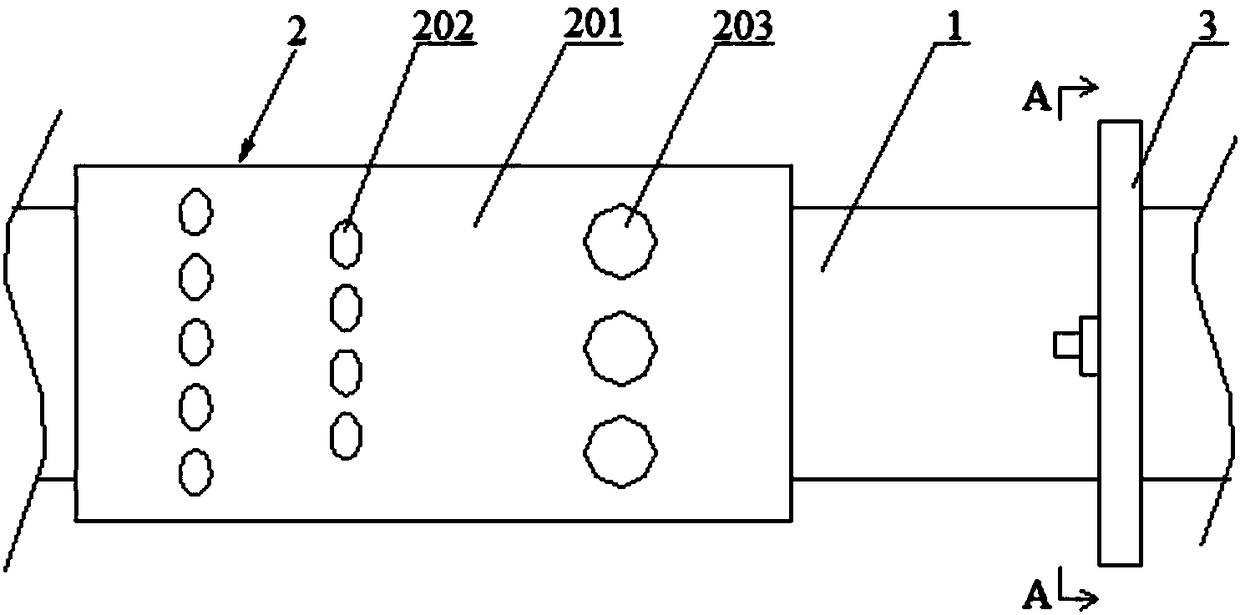

[0114] Such as figure 1As shown, the direction indicated by the arrow is the running direction of the sintering machine trolley 1. A sintering machine material level diagnosis and self-adaptive control device includes a sintering machine trolley 1 and an ignition furnace 2 . The ignition furnace 2 includes a furnace body 201 , an ignition burner 202 and a heat preservation burner 203 . The furnace body 201 of the ignition furnace 2 is arranged on the upper part of the sintering machine trolley 1 . Both the ignition burner 202 and the heat preservation burner 203 are arranged on the top of the furnace body 201 , and the ignition burner 202 is located upstream of the heat preservation burner 203 . The device also includes a material surface video recognition device 3 arranged downstream of the ignition furnace 2 and above the sintering machine trolley 1 in the running direction of the sintering machine trolley 1 . The ignition furnace 2 includes nine ignition burners 202 . T...

Embodiment 2

[0119] Such as Figure 5 As shown, embodiment 1 is repeated, except that the device also includes a blowing hood 4 and a gas blowing device 5 arranged downstream of the material level video recognition device 3 . The gas injection device 5 includes a gas injection main pipe 501 , a gas injection branch pipe 502 and a gas injection pipe 503 . The blowing cover 4 is located on the upper part of the sintering machine trolley 1 . The gas injection main pipe 501 is arranged on the outside of the injection cover 4 . The gas injection pipe 503 is arranged above the sintering machine trolley 1 and the gas injection pipe 503 is located in the injection hood 4 . One end of the gas injection branch pipe 502 is connected to the gas injection main pipe 501 and the other end is connected to the gas injection pipe 503 . The gas injection pipe 503 is provided with a gas injection hole 504 . Nine gas injection pipes 503 are connected to each gas injection branch pipe 502 .

[0120] Such a...

Embodiment 3

[0123] A method for diagnosing the intelligent material surface of a sintering process, the method comprising: observing the whitening or yellowing of the sintering ore material surface on the sintering machine trolley 1 through the material surface video recognition device 3 in Example 1, and then judging the sintering ore The sintering condition of the material surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com