Polar power generation cabin with temperature equalizing device

A technology for generators and cabins, applied to fuel heat treatment devices, charging systems, engine components, etc., can solve problems such as uneven distribution of temperature up and down, achieve the effects of increasing temperature, avoiding damage and failure, and improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

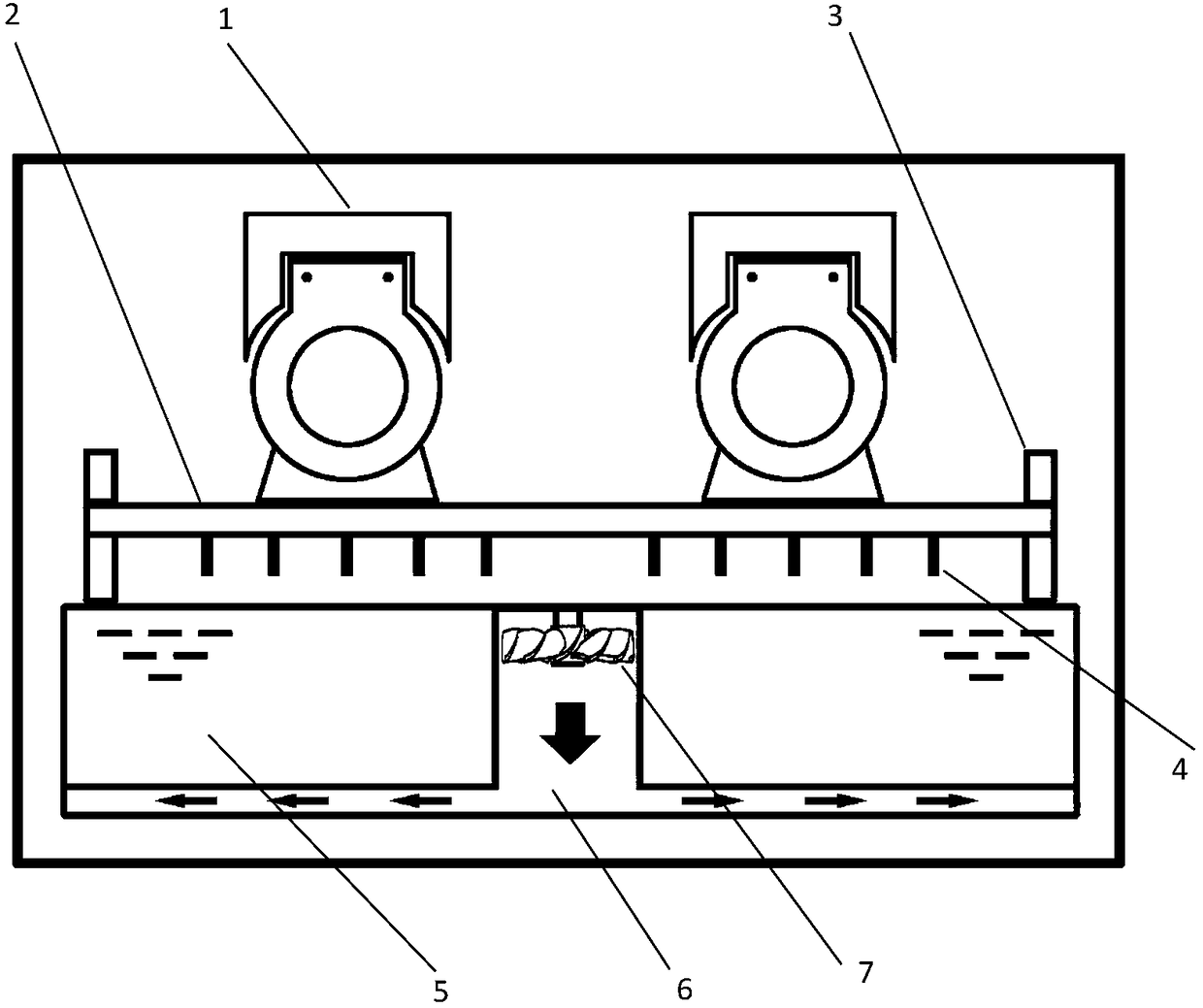

[0027] Carry out further detailed description below in conjunction with accompanying drawing:

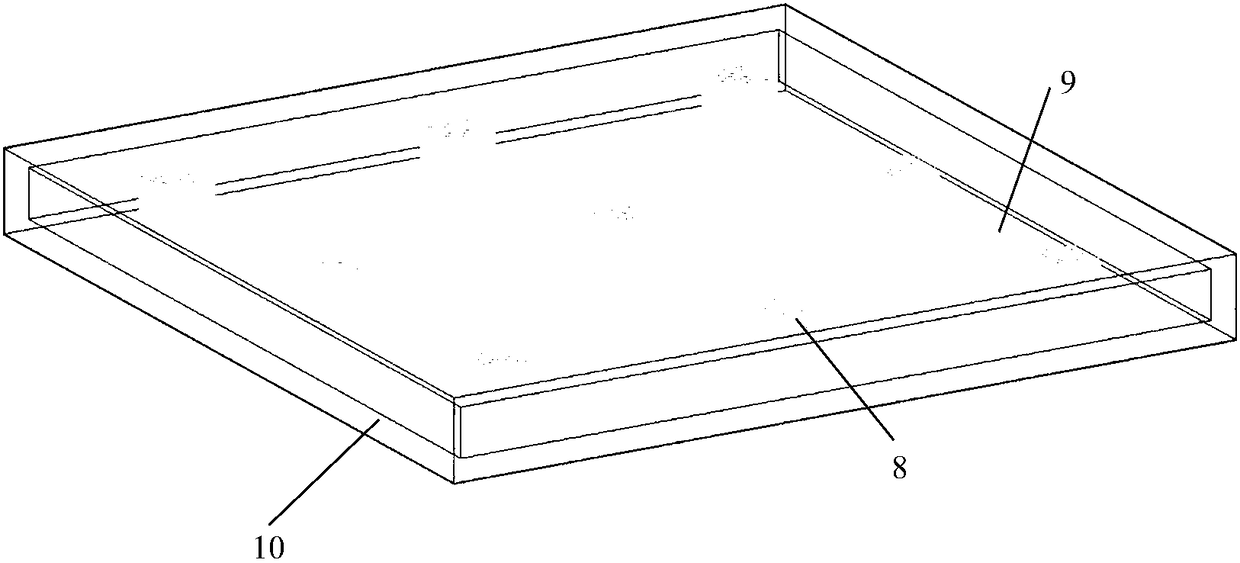

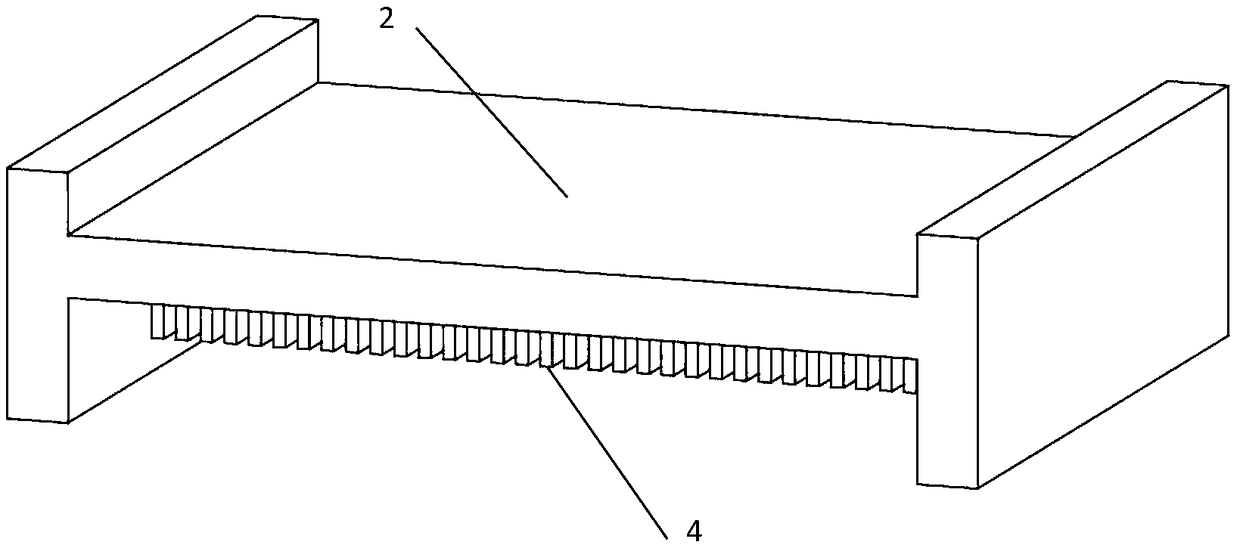

[0028] figure 1A schematic structural diagram of the polar power generating cabin of the present invention is given, including an anti-gravity flat heat pipe, an air equalizing device and a fuel preheating and thawing device. The specific structure includes: diesel generator 1; anti-gravity flat heat pipe 2; air uniform temperature device 3; ribs 4; oil storage tank 5; The air temperature equalization device 3 is an "H"-shaped metal support frame, and the anti-gravity flat heat pipe 2 is the supporting platform of the air temperature equalization device 3, which is used to place the diesel generator 1, and ribs are installed on the lower part of the anti-gravity flat heat pipe 2 Sheets are used to increase the heat transfer area and enhance the heat transfer effect. The heat of the casing of the diesel generator 1 is transferred downward through the anti-gravity flat heat pipe 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com