Longitudinal drawing method and device of two-directional drawn polyester film

A technology of biaxial stretching polyester and longitudinal stretching, which is applied to flat products, household utensils, and other household utensils. It can solve the problems of reduced film thickness uniformity, easy film breakage, and poor thickness, etc., to achieve thickness uniformity Good, high stretching efficiency, less film breaking times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

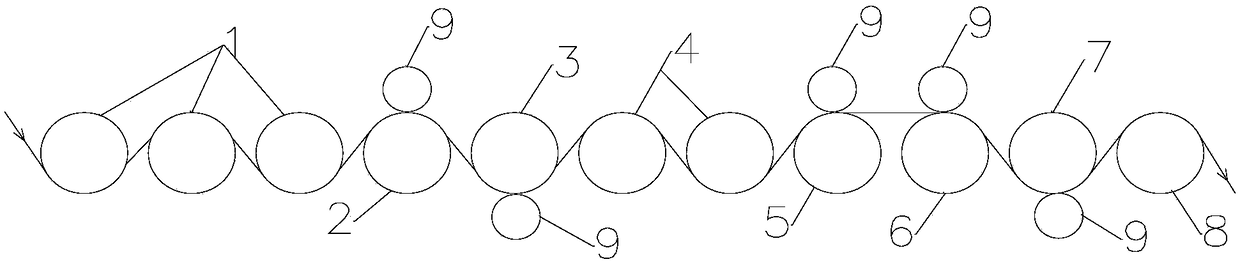

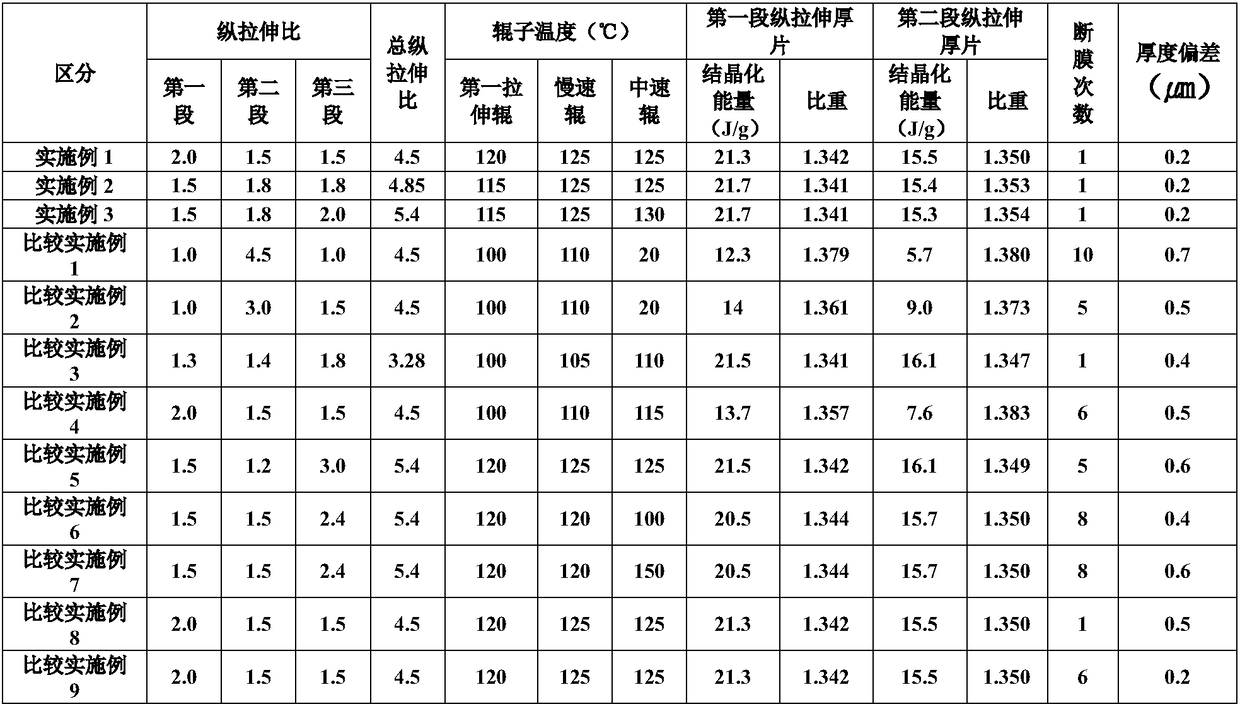

[0025] The polyester chips with an intrinsic viscosity of 0.63 dL / g are melt-extruded through a die at a slab forming speed of 60 m / min at 280° C. to produce unstretched slabs. exist figure 1 In the longitudinal stretching device, the roll temperature of the preheating roll 1 is 100°C, the roll temperature of the first stretching roll 2 is 120°C, the roll temperature of the primary cooling roll 3 is 30°C, and the roll temperature of the secondary preheating roll is 100°C. 110°C, the roll temperature of the slow roll 5 and the medium speed roll 6 is 125°C, and the roll temperature of the fast roll 7 and the secondary cooling roll 8 is 20°C. Carry out the first segment of longitudinal stretching with a draw ratio of 2.0 times between the primary cooling roll 3, and carry out the second segment of longitudinal stretch with a draw ratio of 1.5 times between the slow roll 5 and the medium speed roll 6, and the medium speed roll 6 Carry out the third section longitudinal stretching...

Embodiment 2

[0027] The slab forming speed in Example 1 is 61.7m / min, the roll temperature of the first stretching roll 2 is 115°C, the stretching ratio of the first segment of longitudinal stretching is 1.5 times, and the stretching ratio of the second segment of longitudinal stretching is 1.5 times. Stretch ratio is 1.8 times, and the draw ratio of the third segment longitudinal stretch is 1.8 times, and the draw ratio of transverse stretch is 3.6 times to carry out, and all the other are consistent with the data of embodiment 1.

Embodiment 3

[0029] The slab forming speed in Example 1 was 45.5 m / min, the roll temperature of the first stretching roll 2 was 115°C, the temperature of the No. 9 roll was 130°C, and the draw ratio of the first longitudinal stretch was 1.5 times, The stretching ratio of the second stage longitudinal stretching is 1.8 times, the stretching ratio of the third stage longitudinal stretching is 2.0 times, and the stretching ratio of the transverse stretching is 4.4 times to carry out, all the other are consistent with the data of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com