A laser welding method for the active region of a metal bipolar plate

A metal bipolar plate, laser welding technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

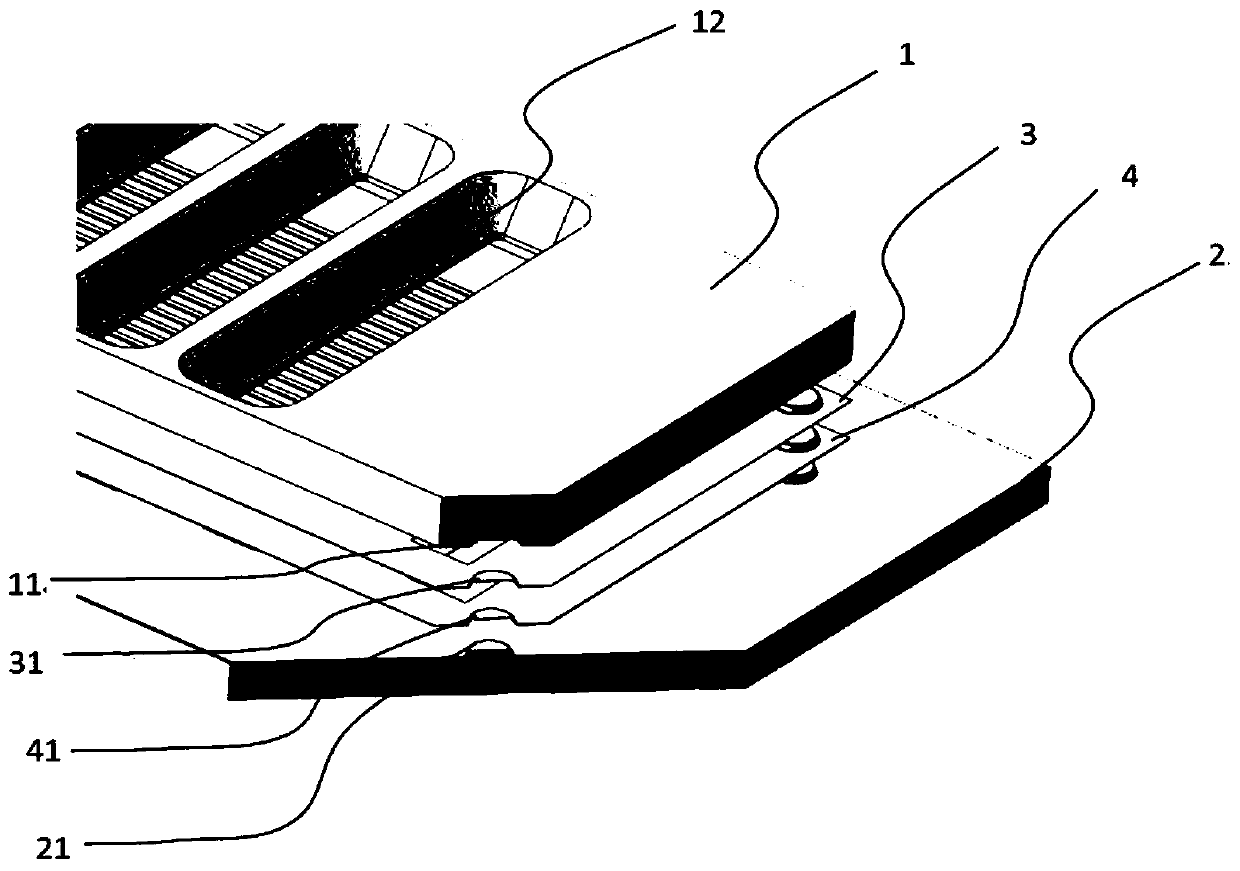

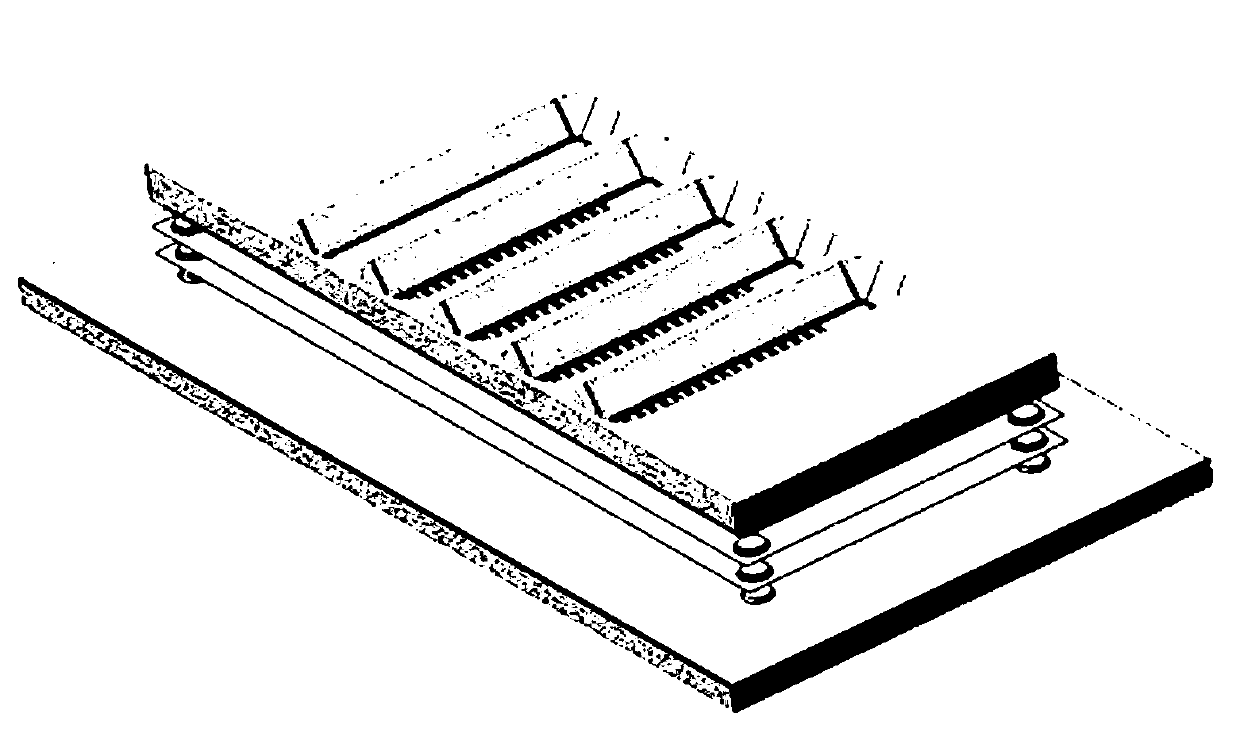

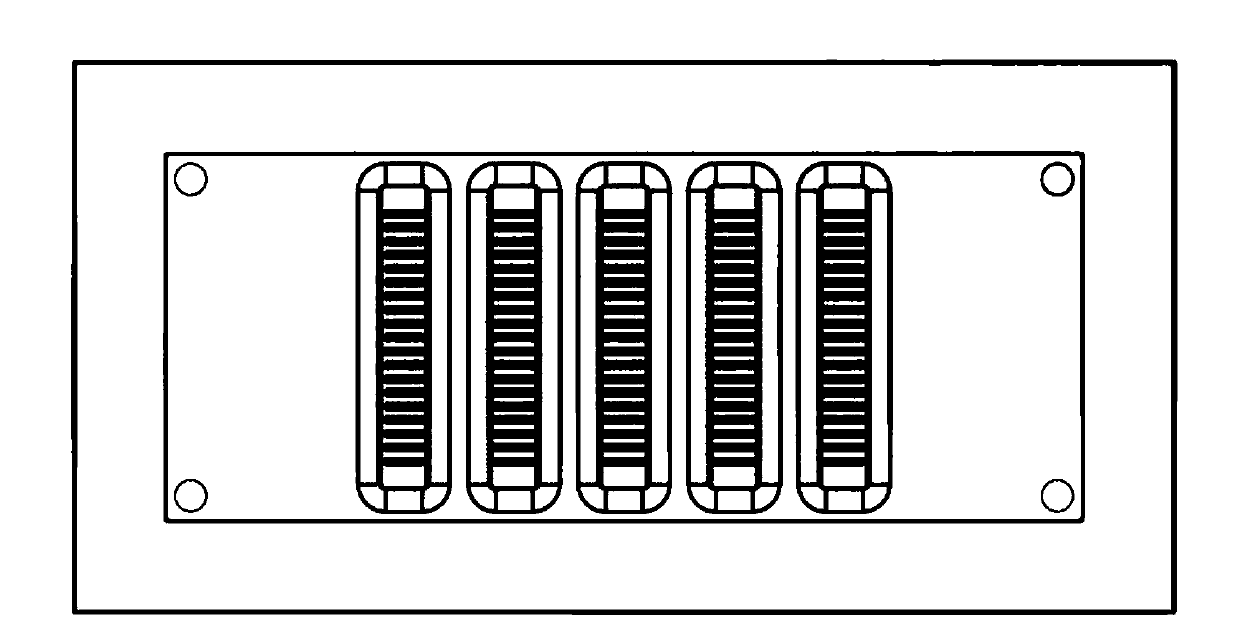

[0039] This embodiment provides a laser welding method for the active region of the metal bipolar plate.

[0040] The method adopts the bipolar plate laser positioning fixture to position the bipolar plate, wherein the bipolar plate and the positioning fixture are provided with corresponding embedable positioning points, and the positioning points on the bipolar plate are set at Outside the active area of the bipolar plate, the positioning fixture is provided with a welding hole for welding the bipolar plate; the laser from the laser light source welds the welding area of the bipolar plate through the welding hole, and the emission power of the laser light source is 90~ 105w, the laser moves at a speed of 80-120mm / s relative to the bipolar plate to be welded and its fixture.

[0041] As an embodiment, preferably, the laser light source moves along a predetermined route for welding. see Figure 5 , is the welding circuit diagram of the welding method of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com