Millimeter-wave high-gain circular polarization horn antenna with loaded single-medium planar lens

A flat lens and horn antenna technology, applied in the directions of waveguide horns, antennas, electrical components, etc., can solve the problems of large volume, multi-layer unit thickness and weight, high processing difficulty, and achieve compact size, light weight and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following combination Figure 1~Figure 9 The technical content, structural features, objectives and effects of the present invention are described in detail through preferred embodiments.

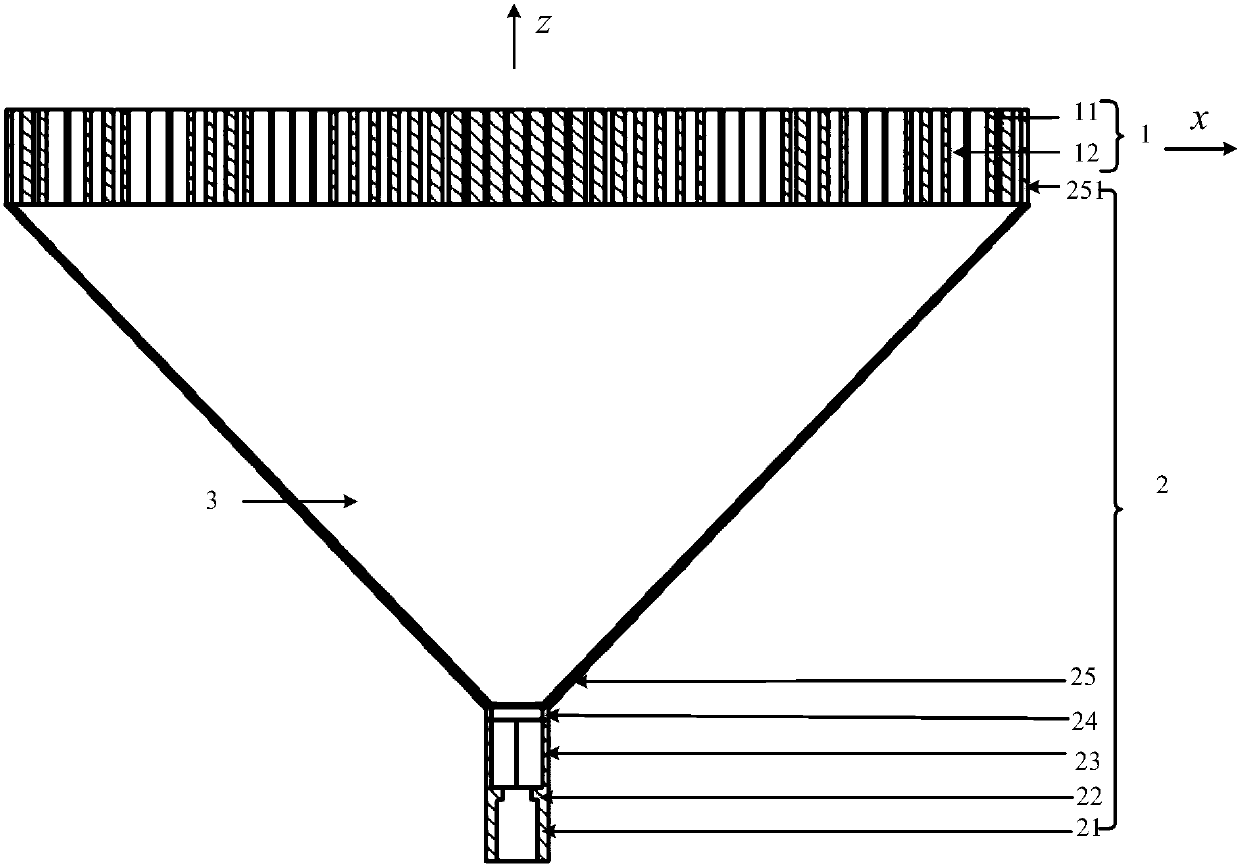

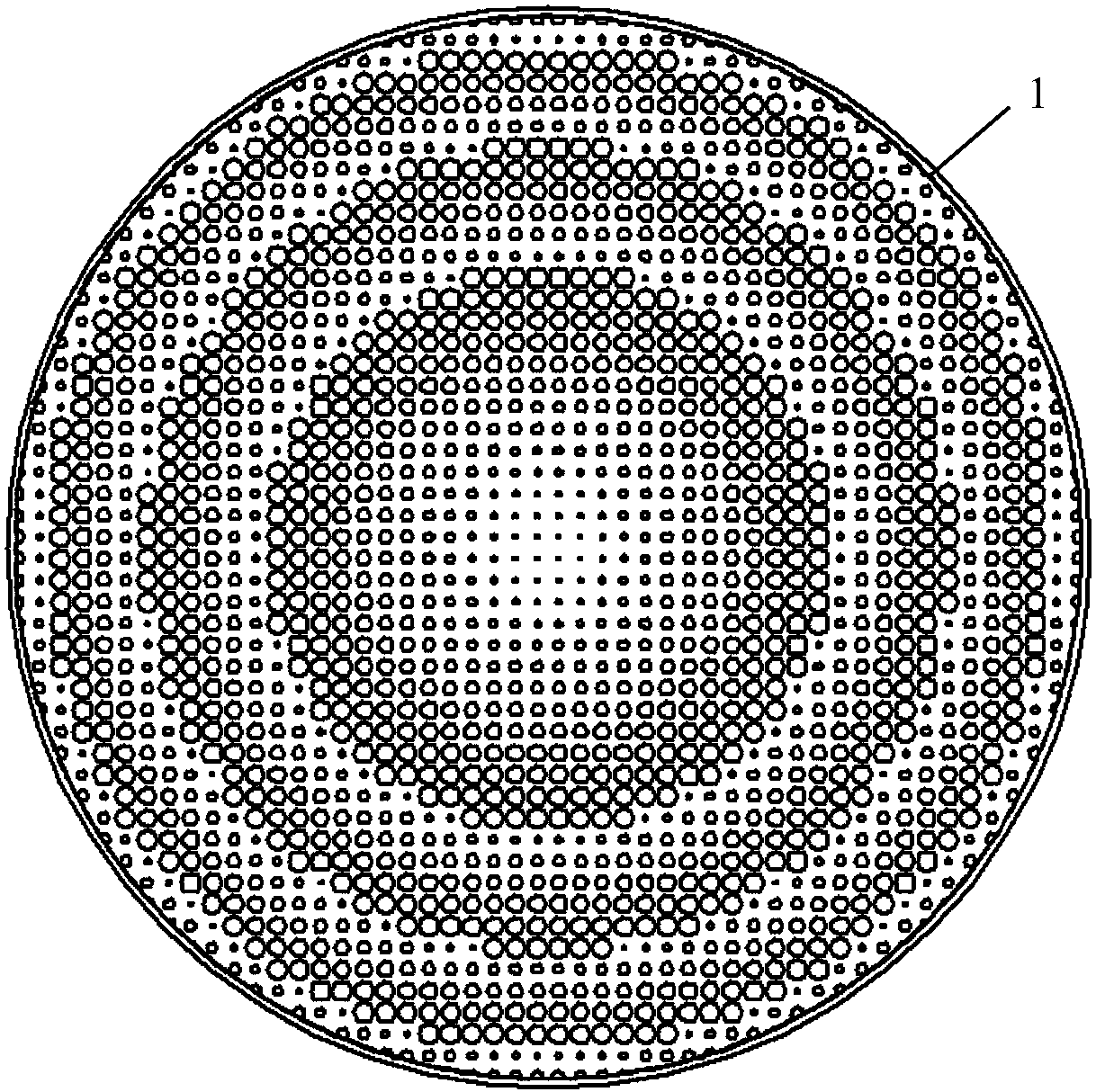

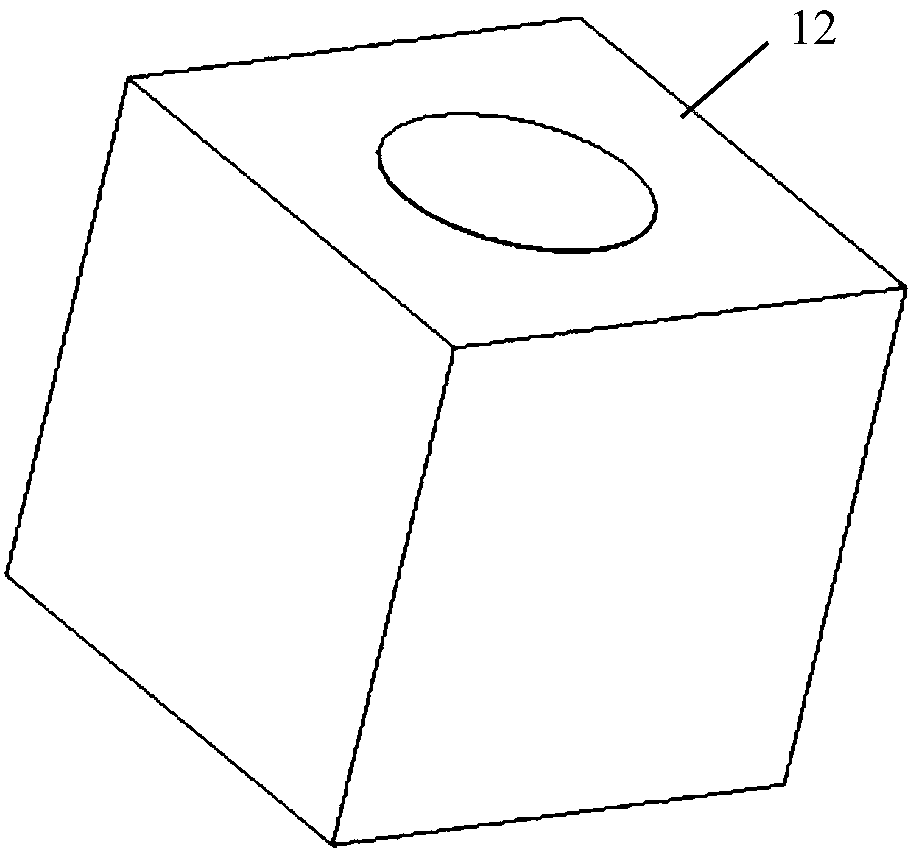

[0032] Such as figure 1 Shown is the millimeter wave high-gain circularly polarized horn antenna loaded with a single dielectric plane lens provided by the present invention, which is a layered structure, including a circularly polarized horn antenna body 2, and covering and arranged on the circularly polarized horn antenna body 2 The single-dielectric plane lens 1 above the top; wherein, the single-dielectric plane lens 1 includes a dielectric substrate 11, and a plurality of array units 12 embedded in the dielectric substrate 11; the circularly polarized horn The antenna body 2 includes a rectangular waveguide 21, a rectangular waveguide transition section 22, a circular waveguide 23 with a chamfered corner, a circular waveguide transition section 24, and a horn-shaped circular op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com