Spinneret plate and method for preparing mesophase pitch base carbon fiber protofilaments

A technology of carbon fiber precursor and mesophase pitch, applied in fiber processing, spinneret assembly, filament/wire forming, etc., can solve the problem of uneven temperature of spinneret, reduce processing and maintenance costs, and achieve uniform temperature , the effect of large overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

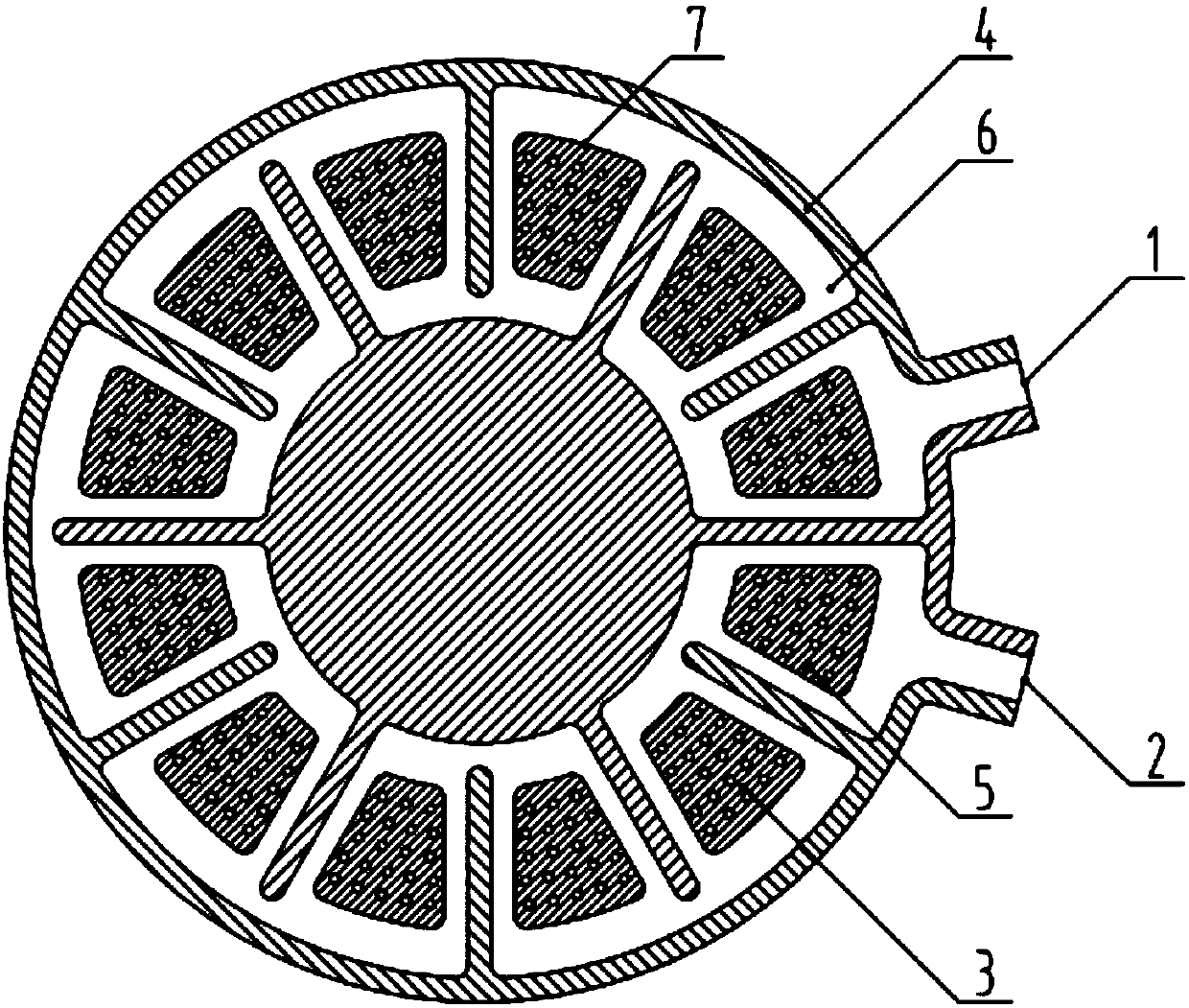

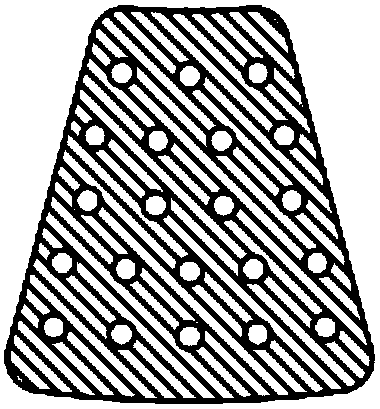

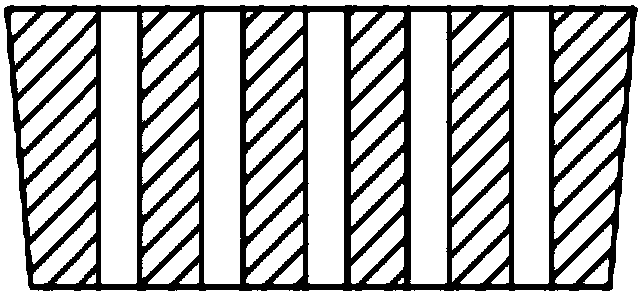

[0030] like figure 1 As shown, the spinneret described in the present invention is a heatable modular spinneret, comprising a spinneret body 4 and a plurality of spinning modules 3, and 12 spinning modules 3 and 12 spinning modules are used in this example. The modules 3 are located on the same circumference and arranged at intervals on the spinneret body 4 . like figure 2 and image 3 As shown, each spinning module 3 is processed into a fan-shaped inverted trapezoidal structure, that is, its horizontal section is fan-shaped, and its longitudinal section in the tangential direction is an inverted trapezoid. Each spinning module 3 is processed according to the processing requirements of the spinning holes. 10 to 100 spinning holes 5 are optimally processed, and the multiple spinning holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com