Electrolysis device for preparing high-purity metallic sodium

An electrolysis device, metal sodium technology, applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve problems such as difficult to realize controllable feeding and continuous operation, and achieve continuous mass production, high safety factor, and enhanced safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

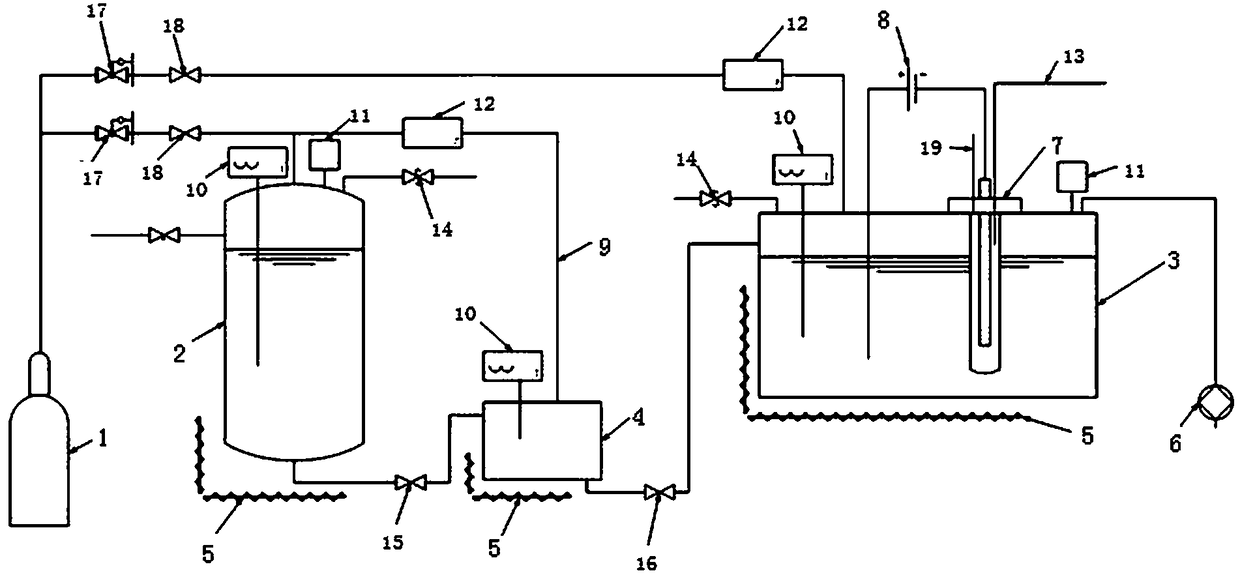

[0030] Such as figure 1 As shown, an electrolysis device for preparing high-purity metallic sodium includes a protective gas source 1 (the protective gas source is inert gas or nitrogen), a crude sodium tank 2 and an electrolytic tank 3. The crude sodium tank 2 is crude sodium The upper part of the container is provided with a valve as an inlet for crude sodium, and the crude sodium is raw sodium with a purity lower than the target product. Both the crude sodium tank 2 and the electrolytic tank 3 are equipped with a heating device 5, the heating device 5 is used to heat the liquid sodium inside to prevent it from solidifying; the protective gas source 1 is connected to the crude sodium tank 2 and the electrolytic tank through a pipeline. 3Connect. Unless otherwise specified, all the pipes through which the sodium metal flows are heated to prevent the sodium metal from solidifying in the pipes. The electrolysis device also includes a vacuum pump system 6. During electrolysis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com