A method for inducing oil in filamentous algae

A filamentous algae and oil technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of limited oil accumulation capacity of microalgae cells, difficulty in giving full play to the oil induction effect, etc. The effect of cumulative efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

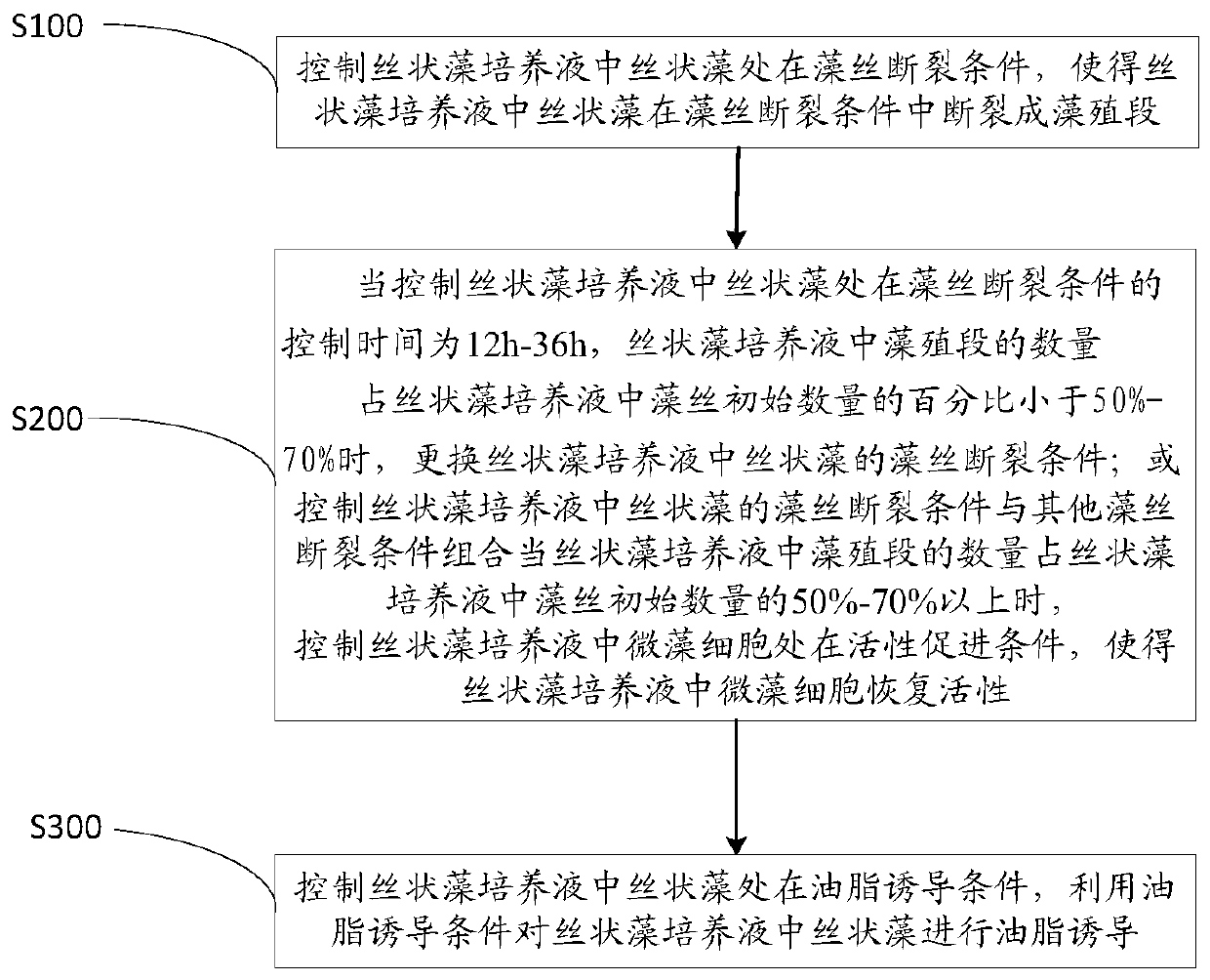

Method used

Image

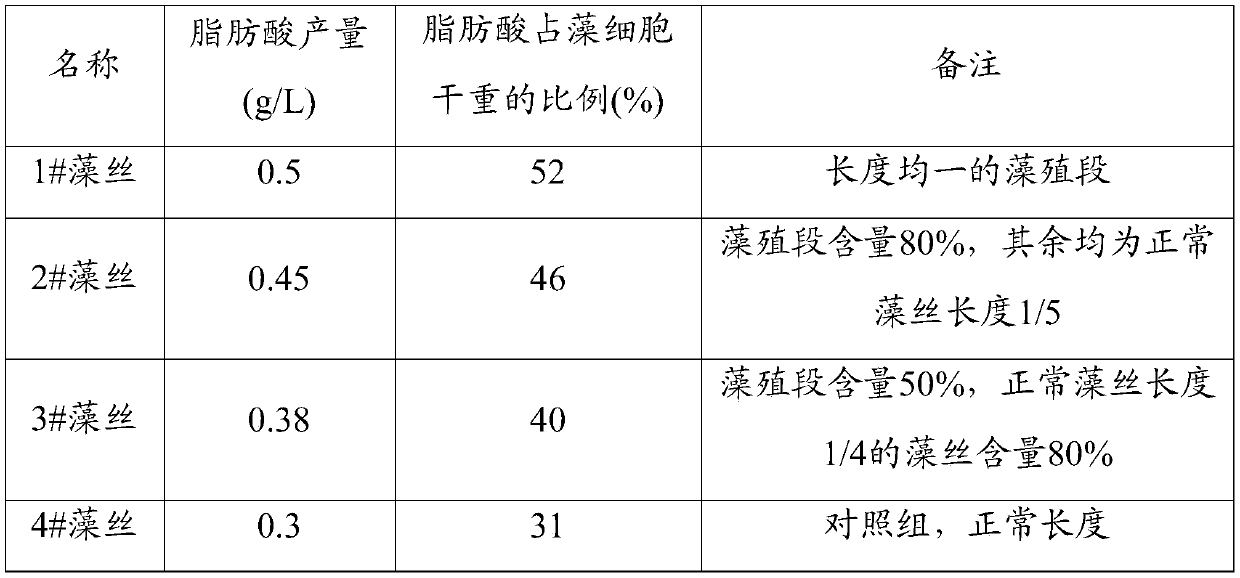

Examples

Embodiment 1

[0044] The first step is to inoculate the Xanthophyll algae species into a 250mL Erlenmeyer flask, and add 100mL of heterotrophic medium (the preparation method of the heterotrophic medium includes: adding glucose aqueous solution in the BG11 medium, and the glucose is calculated as per 1LBG11 medium Add 10g of glucose to the medium), then put it into a shaker and carry out dark shaking culture at a shaking mode of 140 rpm. The algae cell concentration is 1.5g / L;

[0045] In the second step, add 1mol / L hydrochloric acid to the first microalgae liquid, so that the pH value of the first microalgae liquid=3, thereby controlling the yellow hair algae in the first microalgae liquid to start to break under the condition of pH value=3 ;

[0046] Sampling and checking the number of algal filaments every 6 hours: the specific method includes: shake the first microalgae liquid, then draw 20 μL of the first microalgae liquid from the first microalgae liquid and place it on a glass slide...

Embodiment 2

[0057] The first step is the same as the first step in Embodiment 1.

[0058] In the second step, the yellow silk microalgae cells in the first microalgae liquid are collected, and inoculated to the heterotrophic medium without phosphorus and magnesium elements (the preparation method of the heterotrophic medium comprises: in the absence of phosphorus and magnesium Add glucose aqueous solution to the elemental BG11 medium, and add 10 g of glucose per 1 L of BG11 medium without phosphorus and magnesium elements, and the total mass concentration of phosphorus and magnesium in the heterotrophic medium is the same as that of the heterotrophic medium in the first step. 10% of the total mass concentration of phosphorus and magnesium contained in the culture medium), the second microalgae liquid is obtained, the Erlenmeyer flask where the second microalgae liquid is located is sealed, and the second microalgae liquid is controlled to be in an airtight state, and Continue to carry out...

Embodiment 3

[0069]The first step is the same as the first step in Embodiment 1.

[0070] In the second step, the triangular flask where the first microalgae liquid is placed is airtight, and the first microalgae liquid is controlled to be in an airtight state, and continues to shake and cultivate in the dark at 140 rpm in a shaker to reduce the first microalgae liquid. When the dissolved oxygen content in the microalgae liquid reaches 5%, the Xanthophyllium in the first microalgae liquid begins to break; take samples every 6 hours to check the number of algae filaments under the microscope. For the specific method, see the second step of Example 1.

[0071] In the third step, when the first microalgae liquid is controlled to remain in an airtight state for 24 hours, the percentage of the number of algae growth stages in the first microalgae liquid to the initial number of algae filaments is equal to 60%, and the remaining algae filaments are shortened to the first 1 / 4-1 / 3 of the initial l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com