A kind of microalgae cultivation method

A cultivation method and microalgae technology, applied in the field of microalgae cultivation, can solve the problems affecting the increase of microalgae cultivation output, reducing biomass accumulation, and consuming microalgae energy, so as to reduce ineffective respiration, reduce biomass consumption, Reduce the effect of photorespiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

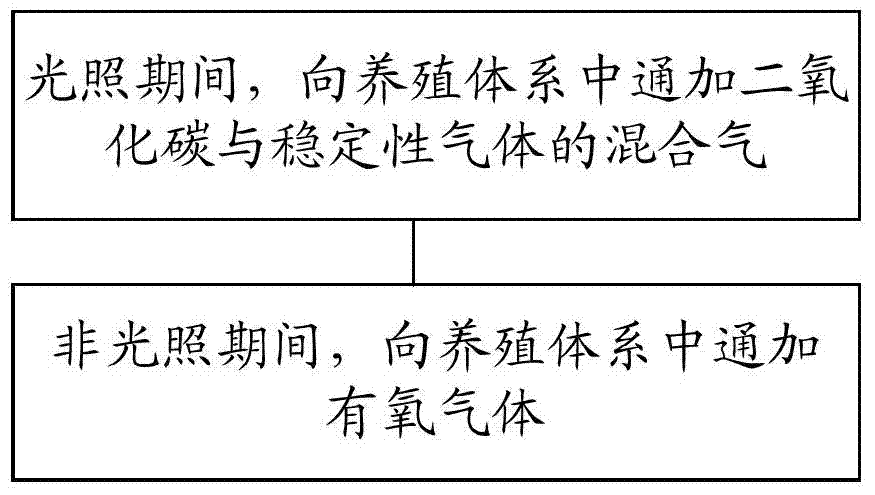

Method used

Image

Examples

Embodiment 1

[0120] A 10cm plate reactor is used to cultivate Nannochloropsis, the suitable pH range for its growth is 6-8, the cultivation scale is 15L, the ventilation required for the cultivation system is 0.3vvm, and the gas ventilation rate is set as 0.27m 3 / h.

[0121] Test group one:

[0122] During the light period, the mixed gas of 3% carbon dioxide and 97% nitrogen of the required ventilation is added, and the pH range of the microalgae culture in the culture system is between 6.5 and 7.5. During the growth process, this condition meets the requirements of the microalgae cells for growth. need;

[0123] During the non-light period, 1% carbon dioxide and 99% air are added to the required ventilation, and the pH range of the culture system is between 7 and 8. During the growth process, this condition meets the growth needs of microalgae cells.

[0124] Several batches were continuously cultivated in this way, and the cultivation period of each batch was 7 days. After each batch...

Embodiment 2

[0135] A 3cm tubular reactor is used to cultivate Chlorella primitive, the suitable pH range for its growth is 6-8, the cultivation scale is 800mL, the ventilation required for the cultivation system is 1vvm, and the gas ventilation rate is set to 0.048 m 3 / h.

[0136] test group:

[0137] During the light period, 5% carbon dioxide and 95% nitrogen are added to the required ventilation, and the pH range of the microalgae culture in the culture system is between 6 and 7. During the growth process, this condition meets the growth needs of the microalgae cells;

[0138] During the non-illumination period, the dissolved oxygen electrode is used to detect the oxygen consumption rate of the microalgae cells, and the required oxygen amount is determined according to the oxygen consumption rate, and then the required air amount is calculated, and the proportion of air added in the required ventilation amount is determined. The test result of oxygen consumption rate is 0.02g oxygen / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com