A method for producing lubricating oil base oil

A technology for lubricating base oil and products, applied in chemical instruments and methods, processing hydrocarbon oil, petroleum industry, etc., can solve problems such as low yield of lubricating base oil products, reduce production costs, improve acidity and acid strength , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

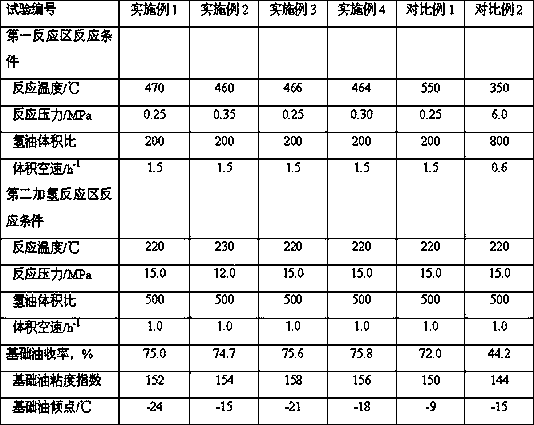

Embodiment 1

[0027] The preparation method of bifunctional catalyst used in the present invention:

[0028] (1) The ZSM-22 molecular sieve prepared according to the method in Example 1 of Chinese patent CN1565969A has an aluminum molar ratio of 95 and a specific surface area of 220m 2 / g, pore volume 0.23mL / g.

[0029] (2) Will (NH 4 ) 2 Ce(NO3) 6 (produced by Beijing Chemical Plant, analytically pure), and water to prepare Ce 2 o 3 An aqueous solution with a concentration of 15% by weight, 1500 grams of the molecular sieve obtained in step (1) and 2000 grams of the above-mentioned cerium-containing aqueous solution are fully mixed, dried at a constant temperature of 120 ° C for 8 hours, and roasted at a constant temperature of 460 ° C for 8 hours to obtain Ce 2 o 3 Cerium-containing ZSM-22 with a content of 15% by weight.

[0030](3) Fully mix 1000 grams of cerium-containing molecular sieve obtained in step (2) and 500 grams of SB alumina powder, then add 100 grams of dilute nitr...

Embodiment 2

[0033] The preparation method of described bifunctional catalyst is the same as embodiment 1, and difference is that used rare earth element compound is La(NO 3 ) 3 ·6H 2 O (produced by Beijing Chemical Plant, analytically pure), La in the lanthanum-containing solution used 2 o 3 The content is 2.5 wt%, the hydrogenation component is palladium, and the palladium-containing compound used is palladium nitrate, wherein palladium is calculated as metal, and the solution concentration is 3.2wt%, to obtain bifunctional catalyst 2, its composition and physicochemical properties are shown in Table 3, The reaction conditions and reaction results are shown in Table 6.

Embodiment 3

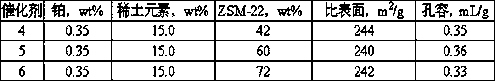

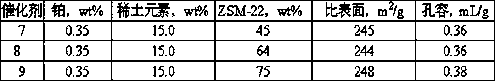

[0035] Using the cerium-containing ZSM-22 molecular sieve and catalyst preparation method prepared in Example 1, three kinds of bifunctional catalysts 4, 5 and 6 were obtained according to the molecular sieve content of 42%, 60% and 72%, respectively, and their composition and physicochemical properties See Table 4. Catalysts 4, 5 and 6 were graded and packed according to the volume ratio of 40:40:30. The reaction conditions and results are shown in Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com