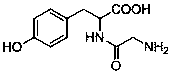

Refining method of N-glycyl-L-tyrosine

A refining method, the technology of tyrosine, applied in the field of purification, can solve the problems of poor refining effect, failure to meet the standard, and failure to reach the standard, and achieve the effect of low cost, environmental friendliness, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] To prepare the crude mozzarella:

[0030] In a 500L reactor, add 250kg of ammonia water, then start stirring and put in 50kg of chloroacetyltyrosine, and react at room temperature. 2.5kg of triethylamine was stirred at 50°C for 30 minutes, cooled to 0-5°C to crystallize for 2 hours, and then centrifuged to obtain a crude product with a dry weight of 42.5kg and a yield of 86.1%. The purity and related substances are shown in Table 1.

[0031] Table 1: Related substances in crude cheese

[0032]

Embodiment 2

[0034] Primary refining of crude cheese:

[0035] In a 500L reactor, put 150kg of water into it, then start stirring and throw in 42.5kg of the crude molasses cheese obtained in Example 1, 2.0kg of triethylamine, heat up to 65°C to dissolve, keep it warm for 30 minutes, and slowly cool down to 0-5°C to crystallize for 2 hours After centrifugation, the dry weight of the primary refined product of cheese was 38.8kg, and the yield was 91.3%. The purity and related substances are shown in Table 2.

[0036] Table 2: Related Substances of Primary Refined Cheese

[0037]

Embodiment 3

[0065] Secondary refining of primary refined cheese:

[0066] In a 500L reactor, put 150kg of water into it, then start stirring and throw in 38.8kg of the first-time refined molasses obtained in Example 2, then add 1.5kg of triethylamine, heat up to 65°C to dissolve, keep it warm for 30 minutes, and slowly cool down to 0- After crystallization at 5°C for 2 hours and centrifugation, the secondary refined product of cheese was obtained with a dry weight of 35.9 kg and a yield of 92.5%. The purity and related substances are shown in Table 8.

[0067] Table 8: Related Substances of Secondary Refined Cheese

[0068]

[0069] The yield of the final product is 72.7%, the purity is 99.8%, the content of glycylglycyltyrosine is 0.13%≤0.3%, and the content of the largest unknown simplex is 0.05%≤0.1%. As can be seen from Examples 1 and 2, the preferred conditions of the USP standard will be reached after one refinement, and the index is far better than the preferred conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com