Sawtooth Vortex Field Acoustic Chaotic Cavitation Device

A vortex field and sawtooth technology, applied in the field of liquid flow chaotic reactors, to achieve the effect of improving efficiency and enhancing the effect of acoustic cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

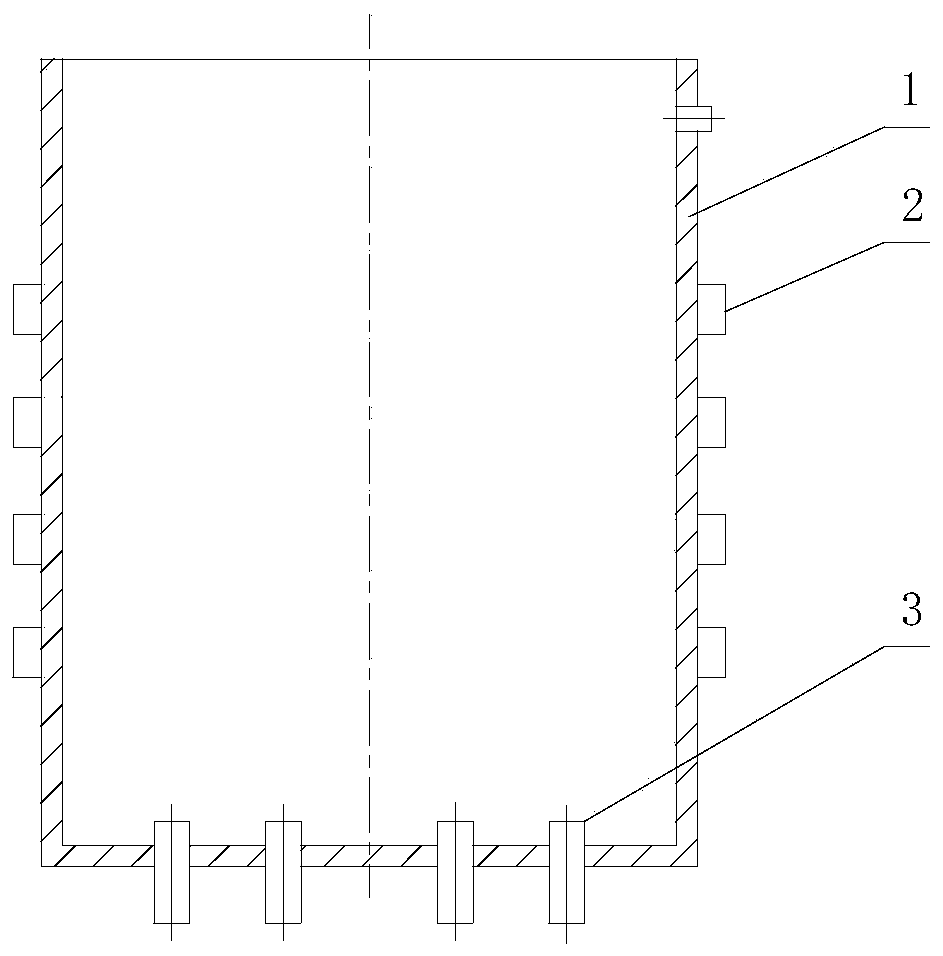

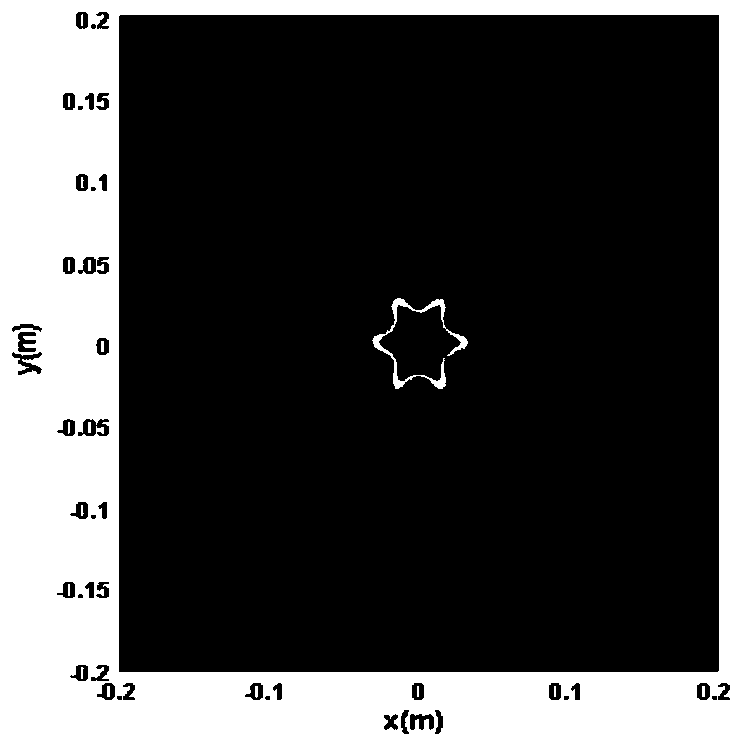

[0029] Such as figure 1 As shown, the sawtooth vortex field acoustic chaotic cavitation device of this embodiment is composed of a reactor 1, a sawtooth vortex field tube 3, and an ultrasonic transducer 2. The reactor 1 is a cylindrical structure with an open top. A water outlet is processed on the upper side wall, and a plurality of water inlets are processed at the bottom of the reactor 1, and a saw-toothed vortex field tube 3 is installed on the water inlet, and the water outlet direction of the saw-toothed vortex field tube 3 is parallel to the axis of the reactor , communicate with the water pump through the serrated vortex field pipe 3, and supply water to the reactor 1. The distance between one saw-toothed vortex field tube 3 and the adjacent saw-toothed vortex field tube 3 is 25 mm, and can be larger. The number of toothed vortex field tubes 3 depends on the size of the reactor 1 . The ultrasonic transducer 2 is installed on the side wall of the reactor 1, and the ult...

Embodiment 2

[0040] The sawtooth vortex field acoustic chaotic cavitation device of this embodiment is composed of a reactor 1, a sawtooth vortex field tube 3, and an ultrasonic transducer 2. The reactor 1 is a cylindrical structure with an open top. A water outlet is processed on the top, and a water inlet is processed on the bottom of the reactor 1, and a serrated vortex field tube 3 is installed on the water inlet. The ultrasonic transducer 2 is installed on the side wall of the reactor 1, and the ultrasonic transducer 2 is distributed in multiple layers from top to bottom, and the distance between the adjacent ultrasonic transducers 2 of the upper and lower layers is 70mm, each layer There are four ultrasonic transducers 2 installed on the same layer, and the four ultrasonic transducers 2 are evenly distributed on the same circumference, facing each other in pairs.

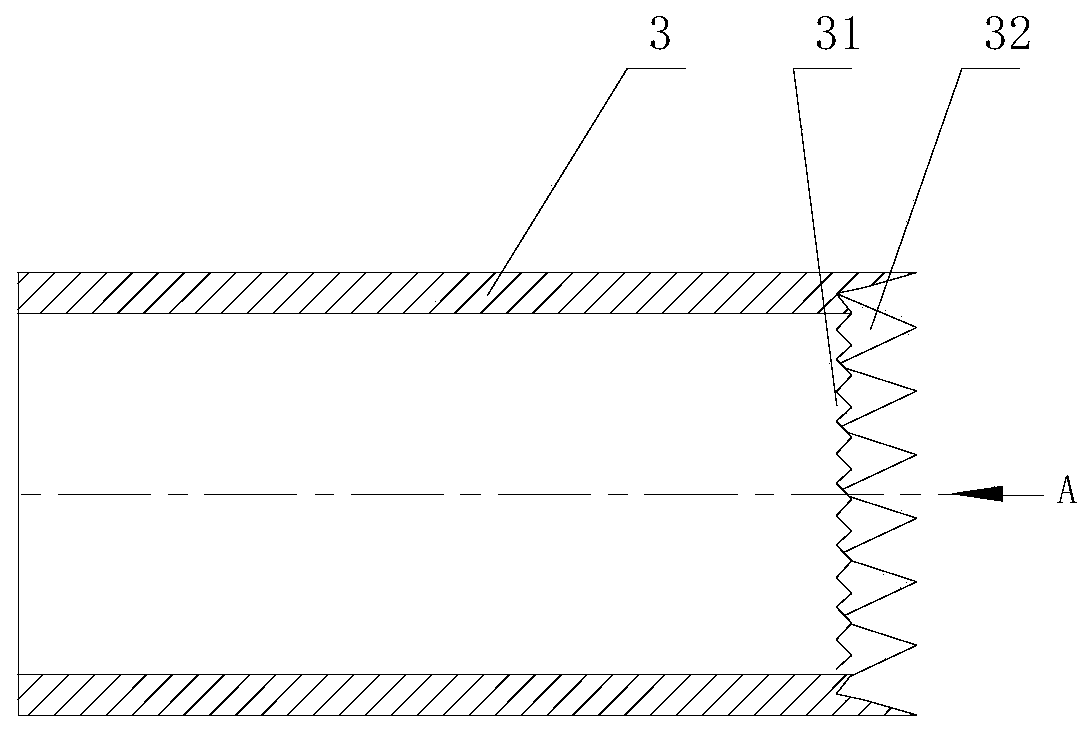

[0041] To further illustrate, the water outlet end of the serrated vortex field pipe 3 of this embodiment includes an in...

Embodiment 3

[0047] The sawtooth vortex field acoustic chaotic cavitation device of this embodiment is composed of a reactor 1, a sawtooth vortex field tube 3, and an ultrasonic transducer 2. The reactor 1 is a cylindrical structure with an open top. A water outlet is processed on the top, and a water inlet is processed on the bottom of the reactor 1, and a serrated vortex field tube 3 is installed on the water inlet. The ultrasonic transducer 2 is installed on the side wall of the reactor 1, and the ultrasonic transducer 2 is distributed in multiple layers from top to bottom, and the distance between the adjacent ultrasonic transducers 2 of the upper and lower floors is 55mm, each layer There are four ultrasonic transducers 2 installed on the same layer, and the four ultrasonic transducers 2 are evenly distributed on the same circumference, facing each other in pairs.

[0048] To further illustrate, the water outlet end of the serrated vortex field pipe 3 of the present embodiment include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com