Guardrail cutting device

A technology for cutting devices and guardrails, applied in positioning devices, maintenance and safety accessories, clamping, etc., can solve the problems of inconvenient guardrail transmission, inability to process guardrails, and increase processing costs, and achieve compact structure, shallow keyway, and improved work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

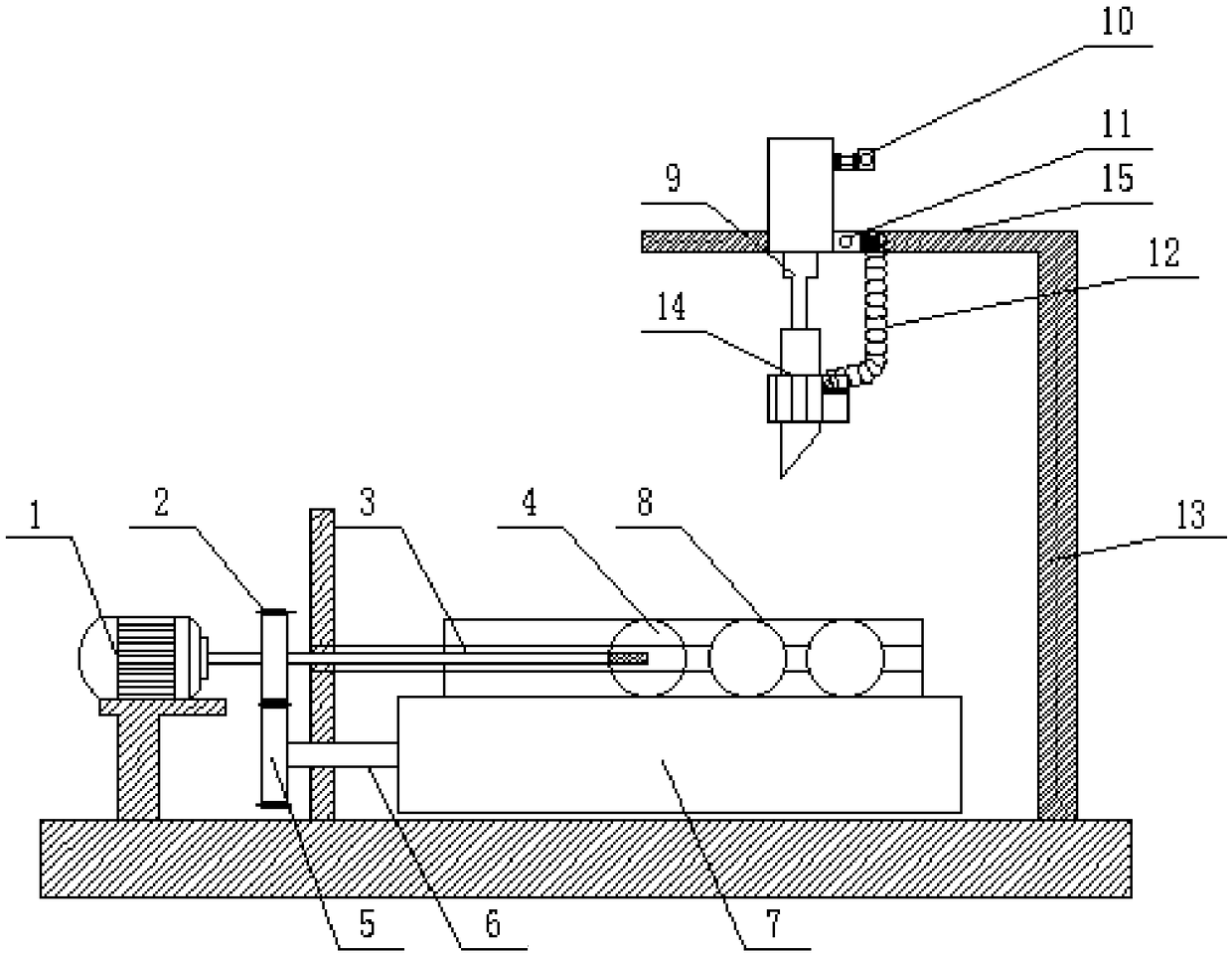

[0014] Instructions attached figure 1 The reference numerals include: motor 1, driving gear 2, flexible shaft 3, supporting round wheel 4, driven gear 5, transmission shaft 6, rotating round wheel 7, guardrail 8, cylinder 9, air intake check valve 10, air outlet Check valve 11, bellows 12, vertical bar 13, cutter 14, cross bar 15.

[0015] like figure 1 As shown, the guardrail cutting device includes a frame, a motor 1 is fixed on one side of the frame, the output shaft of the motor 1 is connected with a flexible shaft 3, and the frame is fixed with a shaft sleeve sleeved outside the flexible shaft 3. A plurality of supporting round wheels 4 are rotatably connected to the shaft sleeve, and the motor 1 drives one of the supporting round wheels 4 for pushing the guardrail 8 to translate through a flexible shaft 3 to rotate. The middle part of the output shaft of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com