Intelligent spraying device

A technology of spraying equipment and spraying robots, which is applied in the direction of spraying devices, manipulators, manufacturing tools, etc., can solve the problems of reduced motion accuracy, reduced production efficiency, and decreased motion accuracy of coating equipment, achieving good tracking effect and improving stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

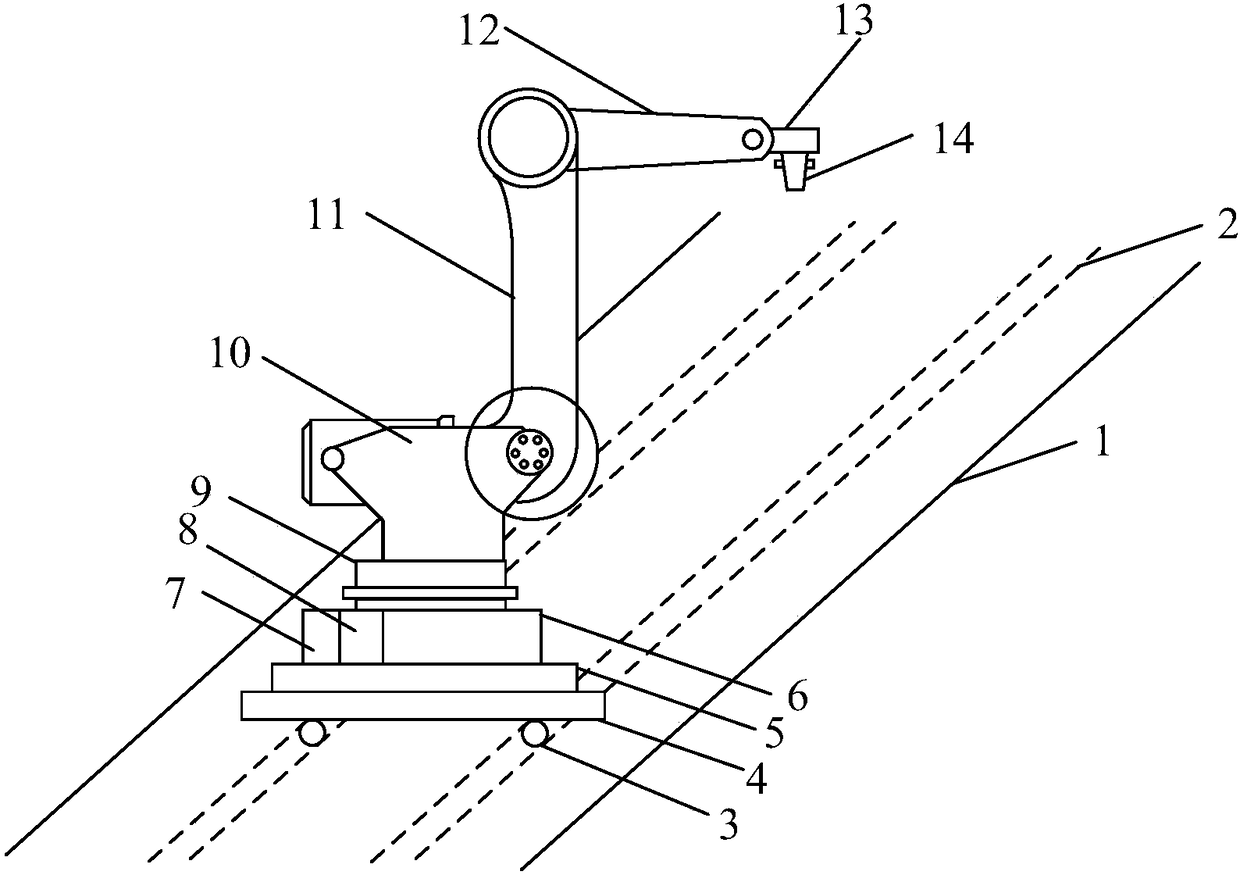

[0038] Such as figure 1 As shown, an intelligent spraying equipment, such as figure 1 As shown, the spraying equipment includes a bottom plate 1 and a spraying robot movable along the bottom plate.

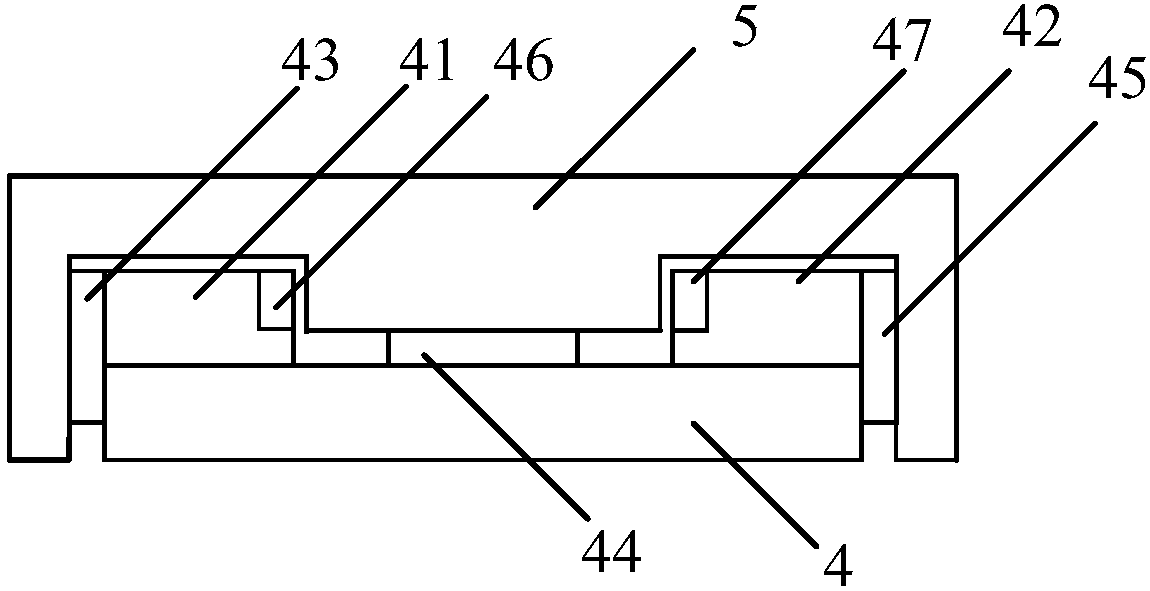

[0039] A plurality of guide rails 2 are arranged on the bottom plate 1; a sliding table is arranged at the bottom of the spraying robot, and the top of the sliding table is connected with a base 6; a driving device is arranged inside the base.

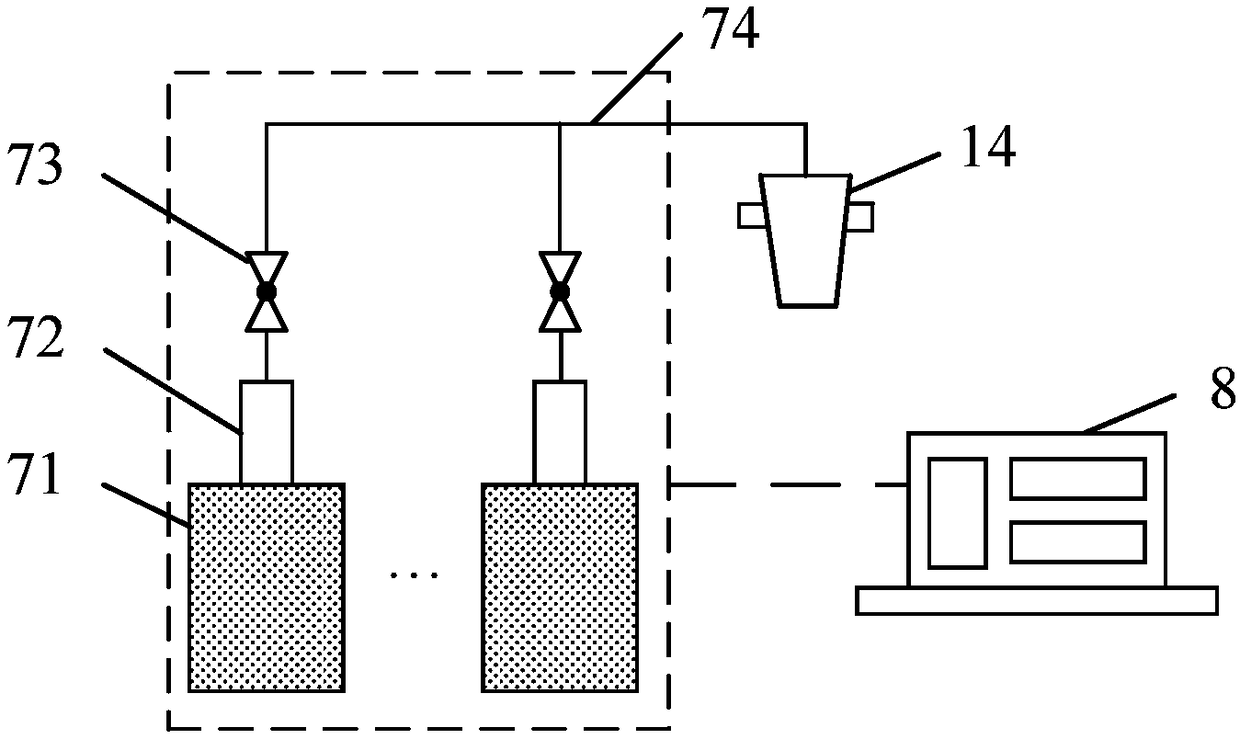

[0040] The base 6 is also provided with a paint supply device 7 and a control module 8, and the control module 8 is connected with the driving device.

[0041] A turntable 9 is arranged on the base 6, and the turntable 9 can rotate in a vertical direction with a rotation range of 0-360 degrees; the turntable 9 is arranged with a boom base 10, which is connected to the boom base 9 The arm 11 is connected by a first rotation pair, the big arm 11 and the forearm 12 are connected by a second rotation pair; the end of the forearm 12 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com