V-shaped flow guiding groove diffuser for draught fan

A technology of diffusers and diversion grooves, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., which can solve the problems of fan surge, large impact loss, separation loss, etc., to reduce friction loss and shorten air flow The effect of distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

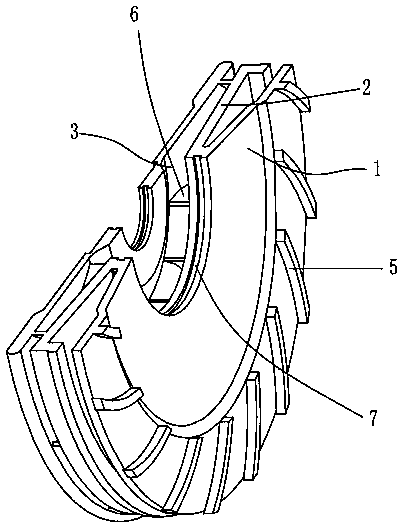

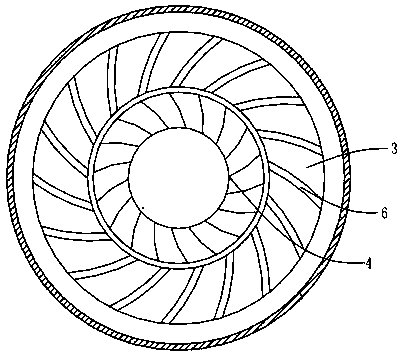

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 2 , a fan V-shaped guide groove diffuser, including a first annular plate body 1, a second annular plate body 2, a third annular plate body 3, the middle of the diffuser is used to set the impeller 4, the first annular plate body The outer ring of an annular plate body 1 is provided with a first arc-shaped flow guide strip 5, and the gap between two adjacent first arc-shaped flow guide strips 5 gradually expands from the inside to the outside, and the second annular plate The body 2 and the third annular plate body 3 are connected by a second arc-shaped guide bar 6, and the second arc-shaped guide bar 6 extends outward from the center of the impeller 4, and the impeller 4 is a copper alloy, composed of 70 % copper, 20% manganese, and 10% silicon are mixed and fired, and the gap between the two adjacent second arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com