Flame-retardant TPO (thermoplastic polyolefin) waterproof coiled material and preparation method thereof

A thermoplastic polyolefin, waterproofing membrane technology, applied in the flame retardant thermoplastic polyolefin TPO waterproofing membrane and its preparation, the field of polymer waterproofing membrane, can solve the problem of poor binding force between calcium carbonate and polyolefin body, polyolefin material Performance degradation, difficult processing and use of products, etc., to achieve outstanding oil resistance and flex resistance, excellent weather resistance and durability, and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

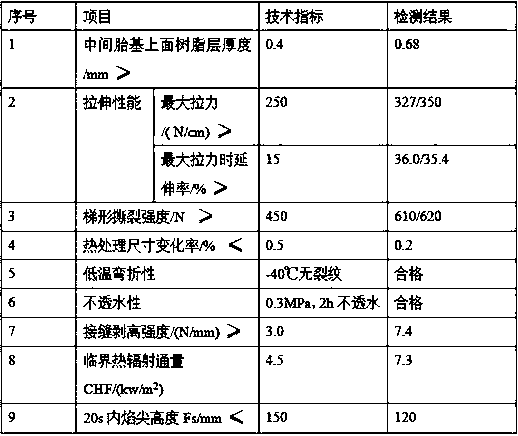

Embodiment 1

[0039] Flame-retardant thermoplastic polyolefin TPO waterproof membrane has a three-layer structure. The upper and lower surfaces are flame-retardant TPO membrane layers, and the middle is a polyester fiber grid fabric reinforcement layer. The TPO membrane layer on the upper surface for white.

[0040] In this embodiment, the flame-retardant TPO coil layer is based on a thermoplastic polyolefin synthetic resin material combined with ethylene-propylene rubber and polypropylene, with a flame-retardant mixture as an auxiliary agent, and modified nano-calcium carbonate as a base material. Filler is also prepared with anti-aging agent, tackifier, bridging agent, dispersant, softener and toner.

[0041] In this embodiment, the amount of each component in the flame-retardant TPO coiled material layer can be adjusted according to actual needs. Preferably, the composition of the TPO coiled material layer is, in parts by weight:

[0042] Flame-retardant TPO membrane layer on the upper ...

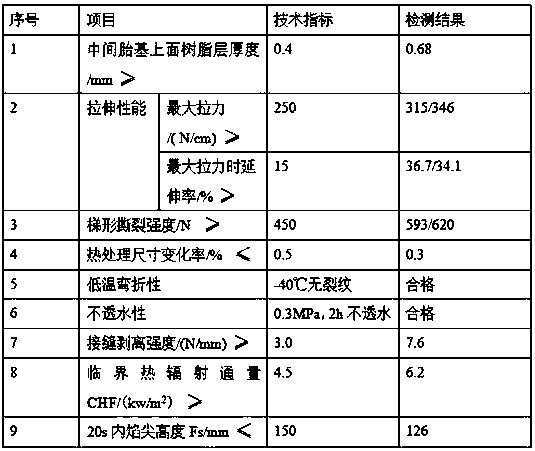

Embodiment 2

[0053] Flame-retardant thermoplastic polyolefin TPO waterproof membrane has a three-layer structure. The upper and lower surfaces are flame-retardant TPO membrane layers, and the middle is a polyester fiber grid fabric reinforcement layer. The TPO membrane layer on the upper surface for white.

[0054] In this embodiment, the flame-retardant TPO coil layer is based on a thermoplastic polyolefin synthetic resin material combined with ethylene-propylene rubber and polypropylene, with a flame-retardant mixture as an auxiliary agent, and modified nano-calcium carbonate as a base material. Filler is also prepared with anti-aging agent, tackifier, bridging agent, dispersant, softener and toner.

[0055] In this embodiment, the amount of each component in the flame-retardant TPO coiled material layer can be adjusted according to actual needs. Preferably, the composition of the TPO coiled material layer is, in parts by weight:

[0056] Flame-retardant TPO coil layer on the upper surf...

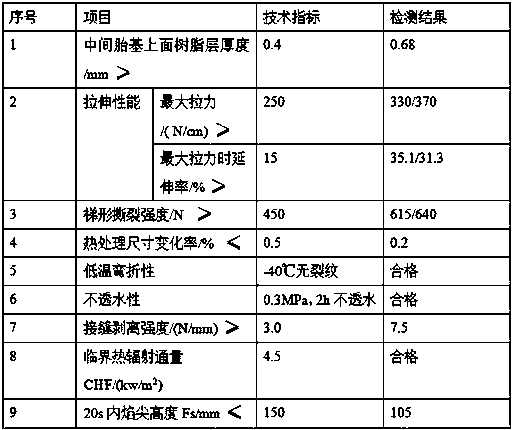

Embodiment 3

[0067] Flame-retardant thermoplastic polyolefin TPO waterproof membrane has a three-layer structure. The upper and lower surfaces are flame-retardant TPO membrane layers, and the middle is a polyester fiber grid fabric reinforcement layer. The TPO membrane layer on the upper surface for white.

[0068] In this embodiment, the flame-retardant TPO coil layer is based on a thermoplastic polyolefin synthetic resin material combined with ethylene-propylene rubber and polypropylene, with a flame-retardant mixture as an auxiliary agent, and modified nano-calcium carbonate as a base material. Filler is also prepared with anti-aging agent, tackifier, bridging agent, dispersant, softener and toner.

[0069] In this embodiment, the amount of each component in the flame-retardant TPO coiled material layer can be adjusted according to actual needs. Preferably, the composition of the TPO coiled material layer is, in parts by weight:

[0070] Flame-retardant TPO membrane layer on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com