Manufacturing method of antibacterial plastic tablecloth

The technology of an antibacterial plastic and a manufacturing method, which is applied in the field of tablecloth material production, can solve the problems of complex manufacturing process, poor antibacterial effect and high cost, and achieve the effects of low cost, good antibacterial and flocculation effects, and good environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

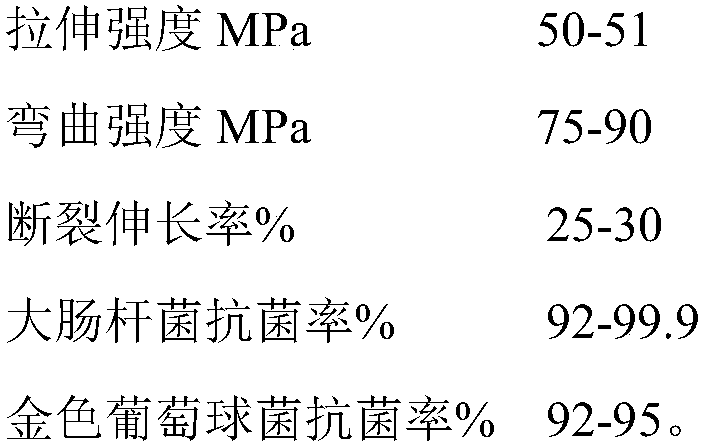

Embodiment 1

[0034] The existing ordinary plastic tablecloths are not environmentally friendly, easy to smell, and not durable enough. The present invention proposes antibacterial plastic tablecloth materials. Chemical performance, use safety, durability and dimensional stability, reduce odor and also improve stain resistance of tablecloths. And it can be made by recycling domestic plastics, which has low cost and is more environmentally friendly.

[0035] The main types of existing living plastics are polyethylene, polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS, ABS), polyamide, etc., which are mixed with various adhesives, coatings, etc. Among them, the existing technology directly separates various plastics before making them, which is complicated in process and high in cost.

[0036] This scheme directly selects cheap living plastics to decompose and then mixes the plastics, and adds antibacterial agents to obtain the required antibacterial properties. The process used ...

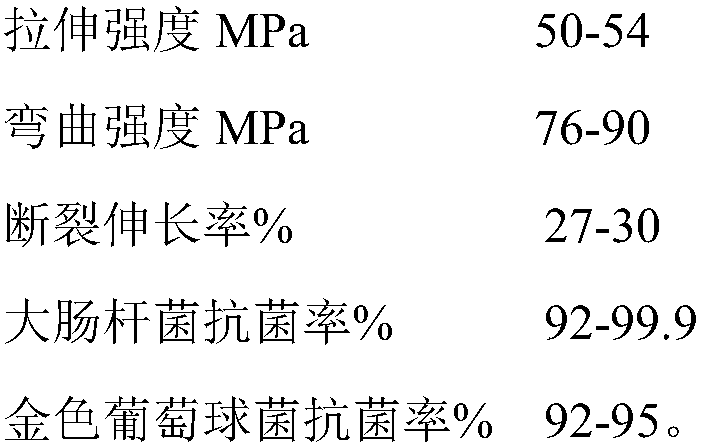

Embodiment 2

[0052] A method for manufacturing an antibacterial plastic tablecloth material, the steps are as follows:

[0053] (1) The existing plastic is fed into the shredder for shredding, and the particle size is shredded to 1-15mm;

[0054] (2) Melt the chopped plastic fragments in a multi-stage hot-melt equipment; the temperature curve is 0-90°C, 10min; 90-180°C, 25min; 180-240°C, 25min; 240-360°C, 20min . Since there are many types of plastics in garbage recycling plastics, and because different types of plastics have different temperatures and effects, the following temperatures respectively act on the following, 0-90°C; soften plastics; 90-180°C; polyethylene , polypropylene is melted; separation; 180-240; polyvinyl chloride, polystyrene, are melted; separation; 240-360 ° C, polyamide is melted; four-stage melting avoids different high temperatures leading to low-temperature plastic cracking , resulting in instability and modification. After each section of plastic is melted, ...

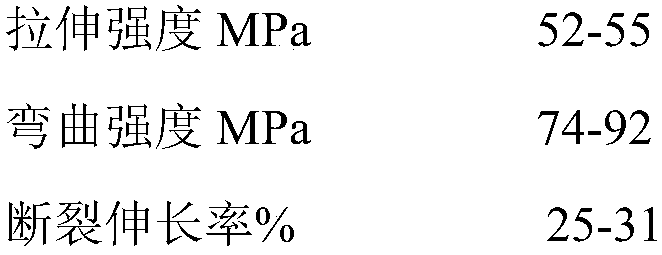

Embodiment 3

[0061] A method for manufacturing an antibacterial plastic tablecloth material, the steps are as follows:

[0062] (1) The existing plastic is fed into the shredder for shredding, and the particle size is shredded to 1-15mm;

[0063] (2) Melt the chopped plastic fragments in a multi-stage hot-melt equipment; the temperature curve is 0-90°C, 10min; 90-180°C, 25min; 180-240°C, 25min; 240-360°C, 20min . Since there are many types of plastics in garbage recycling plastics, and because different types of plastics have different temperatures and effects, the following temperatures respectively act on the following, 0-90°C; soften plastics; 90-180°C; polyethylene , polypropylene is melted; separation; 180-240; polyvinyl chloride, polystyrene, are melted; separation; 240-360 ° C, polyamide is melted; four-stage melting avoids different high temperatures leading to low-temperature plastic cracking , resulting in instability and modification. After each section of plastic is melted, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com