Movable positioning arm for clamping sheet metal part

A technology of sheet metal parts and positioning arms, applied in the field of movable positioning arms, can solve the problems of affecting production efficiency, inaccurate positioning, immovability, etc., and achieve the effect of simple structure, fast positioning and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

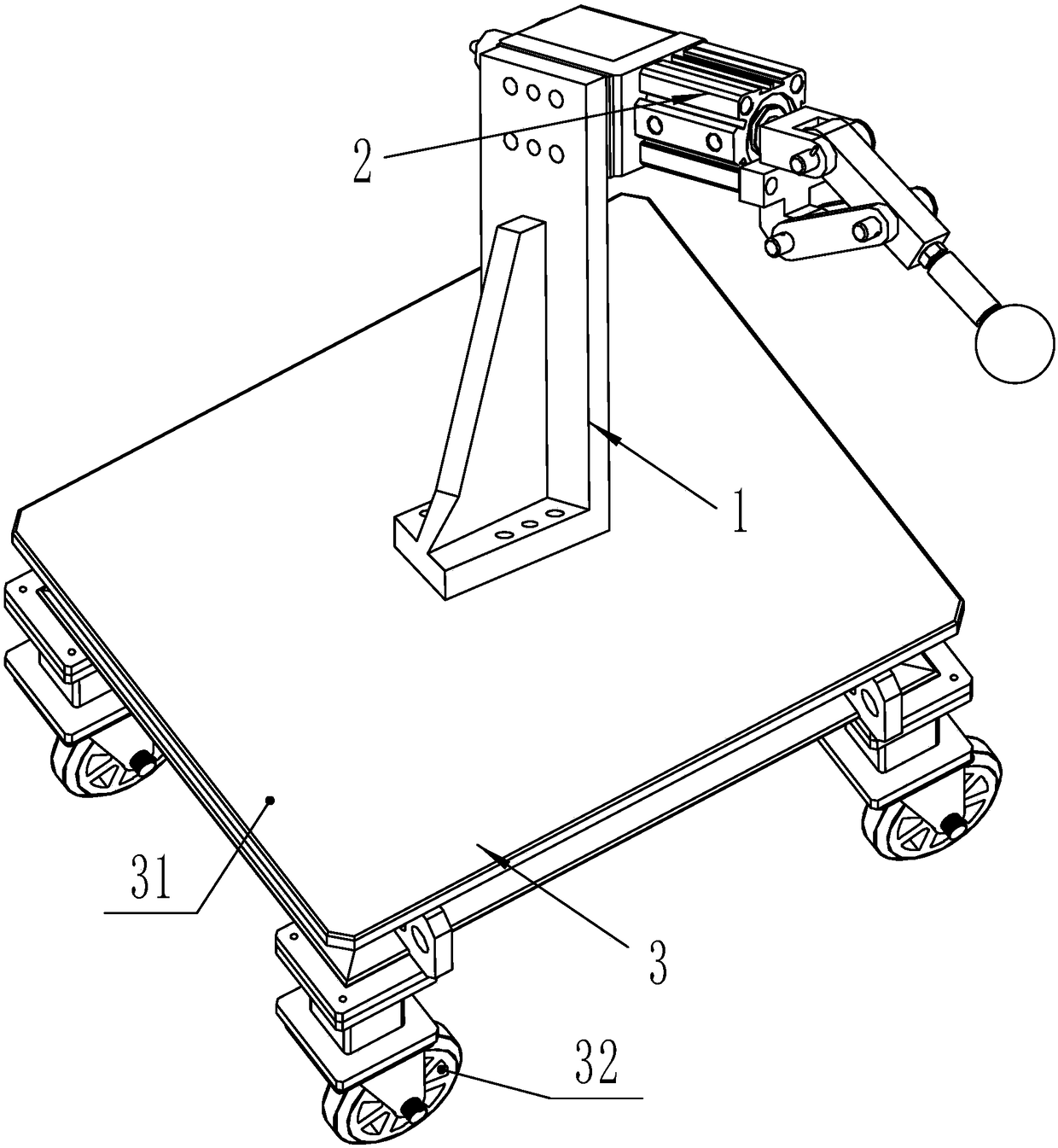

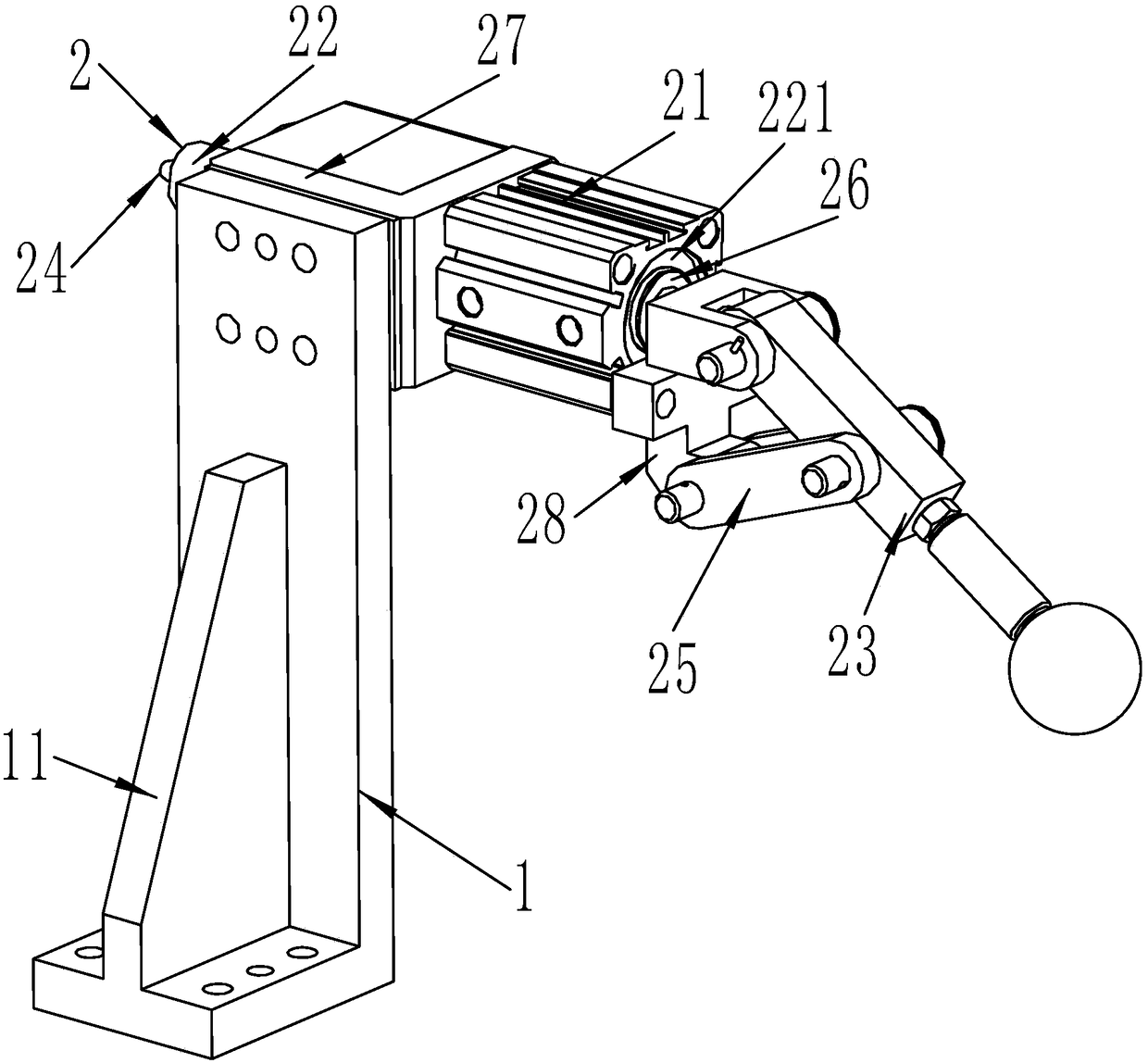

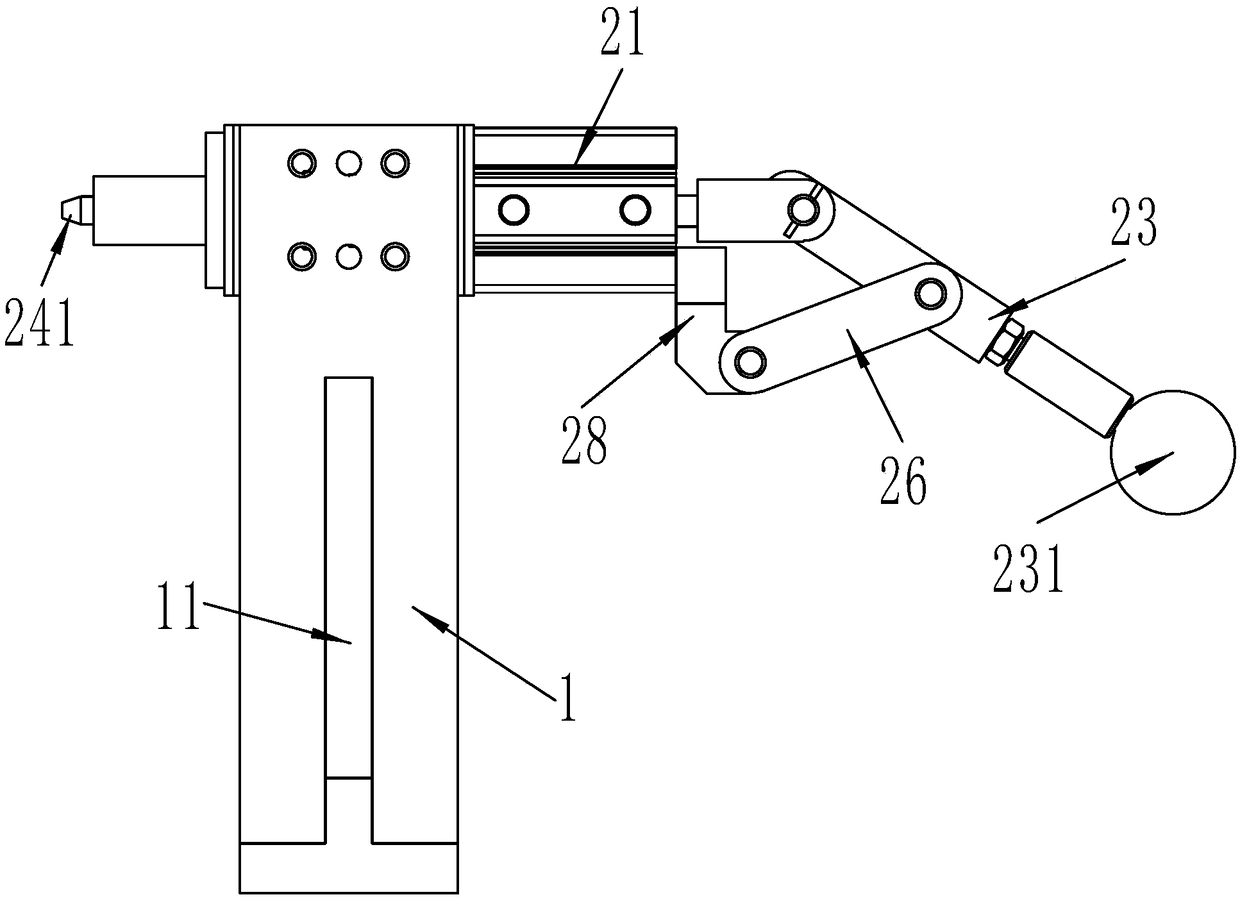

[0018] Such as Figure 1 ~ Figure 4 As shown, a movable positioning arm for sheet metal clamping includes a mobile platform 3, a base 1 disposed on the mobile platform 3 and a positioning mechanism 2 disposed on the base 1; The mobile platform 3 comprises a rectangular platform table top 31 and four universal wheels 32 arranged at the bottom of the platform table top 31. The four universal wheels 32 are located at four corners of the platform table top 31 respectively. The seat 1 is fixedly connected with the platform table 31; the positioning mechanism 2 includes a fixed seat 27, a guide block 21, a guide rod 22, a handle 23 and a positioning pin 24, and the fixed seat 27 is fixedly installed on the base 1 On the upper part, the guide block 21 is fixedly installed on the fixing seat 27, and a guide hole 221 adapted to the guide rod 22 is provided on the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com