Easy-to-move sheet metal part hole position detection tool

A technology of hole position detection and sheet metal parts, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve problems affecting production efficiency, delaying production beats, immovability, etc., achieve high practicability, and reduce the number of preparations , easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

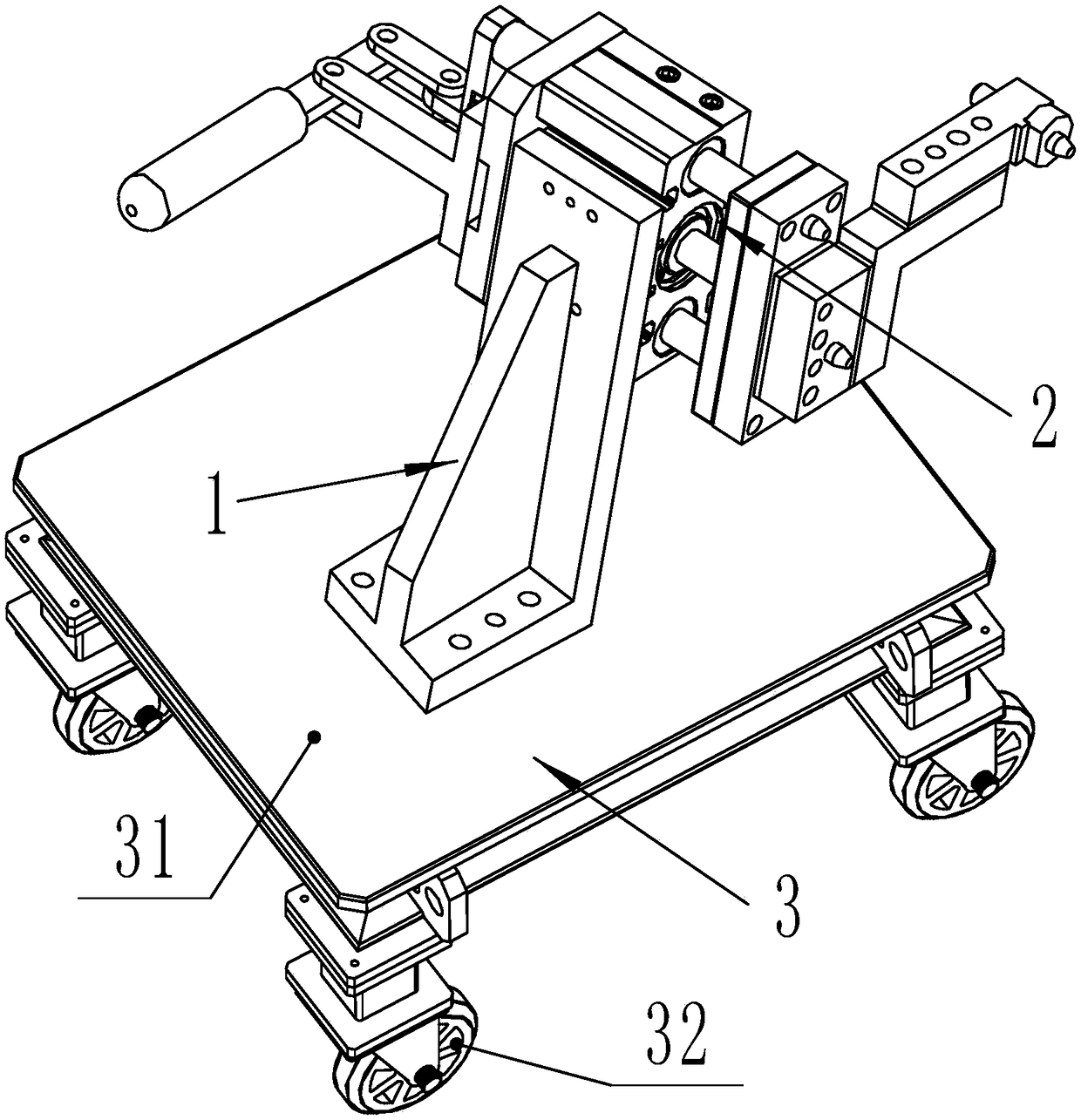

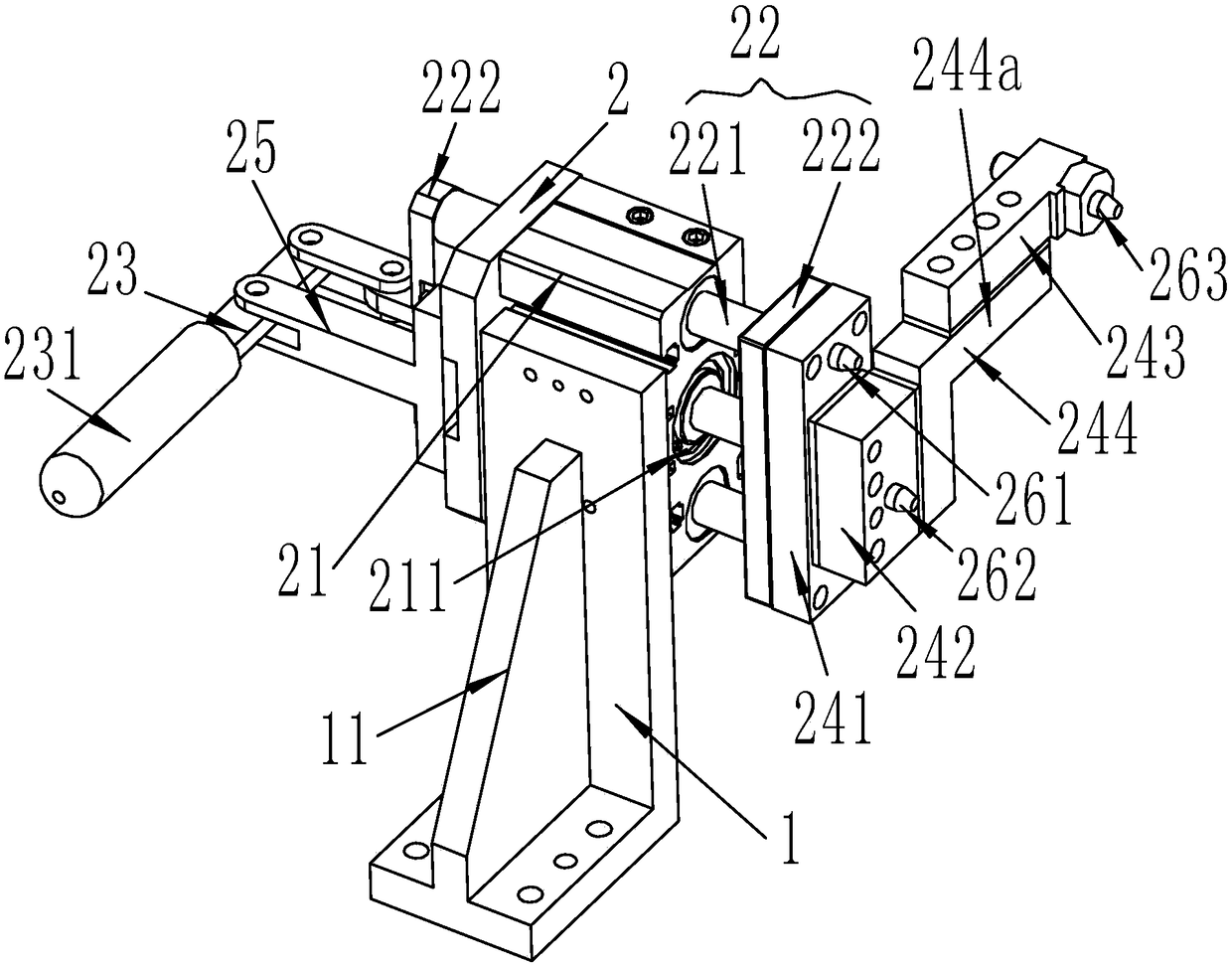

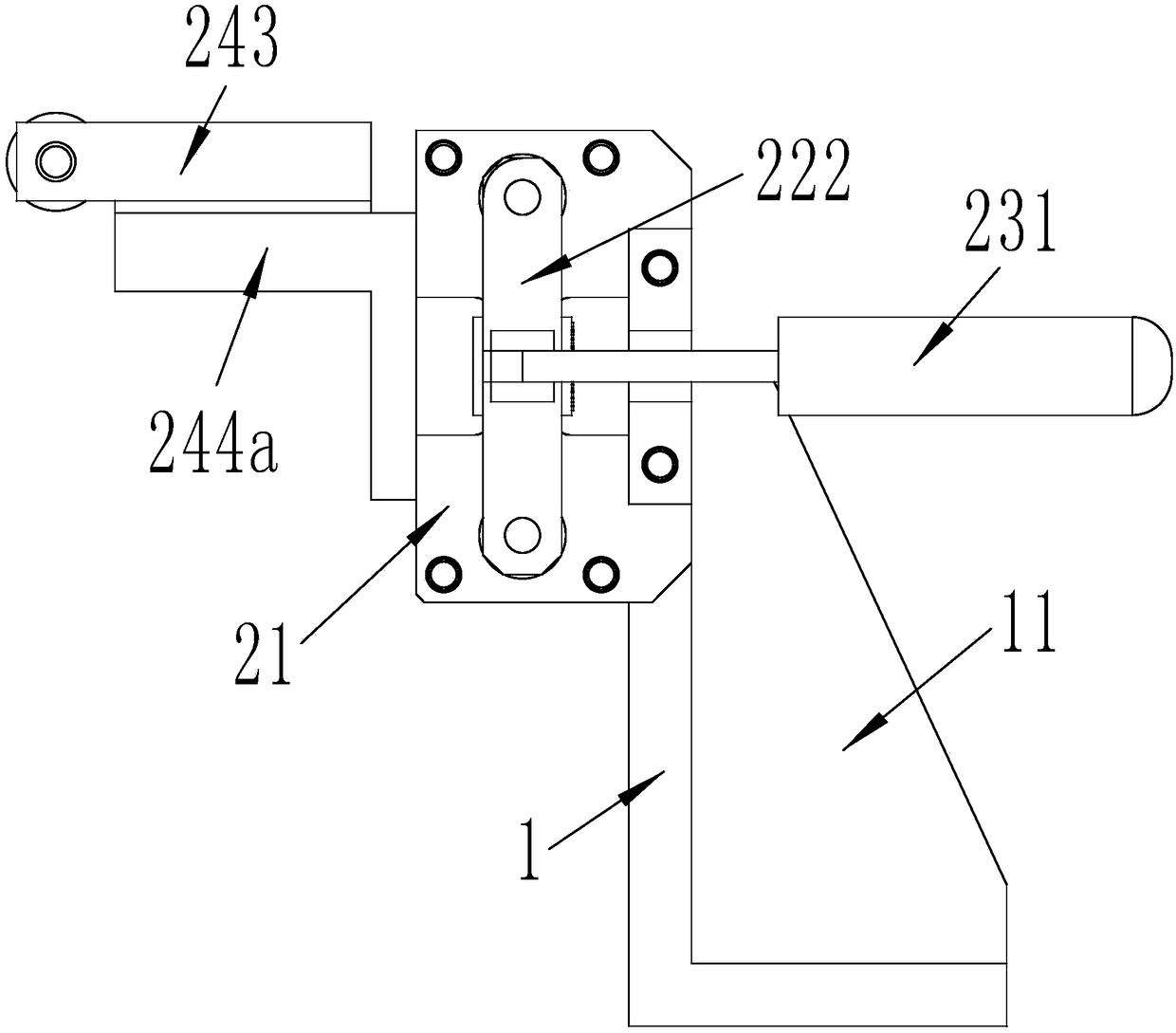

[0018] Such as Figure 1 to Figure 4 , an easy-to-move hole position detection tool for sheet metal parts, including a mobile platform 3, a support base 1 arranged on the mobile platform 3, and a guiding and positioning mechanism 2 arranged on the support base 1; the mobile platform 3 includes Rectangular platform table top 31 and four universal wheels 32 arranged at the bottom of the platform table top 31, the four universal wheels 32 are respectively located at the four corners of the platform table top 31, the support base 1 and the The platform table top 31 is fixedly connected; the guide positioning mechanism 2 includes a guide block 21, a guide rod assembly 22, a handle 23 and a pressing block assembly 24, the guide block 21 is fixedly installed on the support seat 1, and the guide rod One end of assembly 22 is hinged with described handle 23, and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap