High-speed wire production process equipment

A production process and high-speed wire technology, applied in metal processing equipment, manufacturing tools, and driving devices for metal rolling mills, etc., can solve the problems of high technical requirements for equipment maintenance, difficult maintenance, long delivery cycle, etc., and achieve equipment The effect of low maintenance technical requirements, shortened specification replacement time, and simplified production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

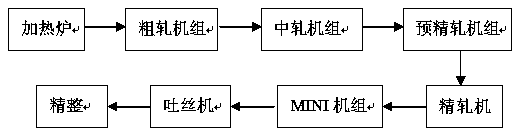

[0030] Such as figure 1 Shown, a kind of high-speed wire rod production line comprises a heating furnace, a rough rolling unit, a middle rolling unit, a pre-finishing rolling unit, a finishing rolling unit, a MINI unit, a laying head, finishing, and the heating furnace, the rough rolling unit, The intermediate rolling unit, the pre-finishing unit, the finishing unit, the MINI unit, the laying head, and the finishing unit are connected in sequence. The MINI unit consists of 2-stand MINI reducing mill and 2-stand MINI sizing mill. The MINI reducing mill and The MINI sizing machine is directly driven by two motors, and has no shifting mechanism and clutch mechanism. Among them, the finishing unit can be 10 racks, 8 racks, or 6 racks. There is a pre-water cooling system in front of the finishing unit, and a closed-loop water cooling system behind the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com