Candle filter element

A candle-type filter and filter element technology, which is applied in the field of filter elements, can solve problems such as inconvenient use, heavy secondary pollution, and low filtration efficiency, and achieve the effects of large flow rate, good effect, and reduced contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

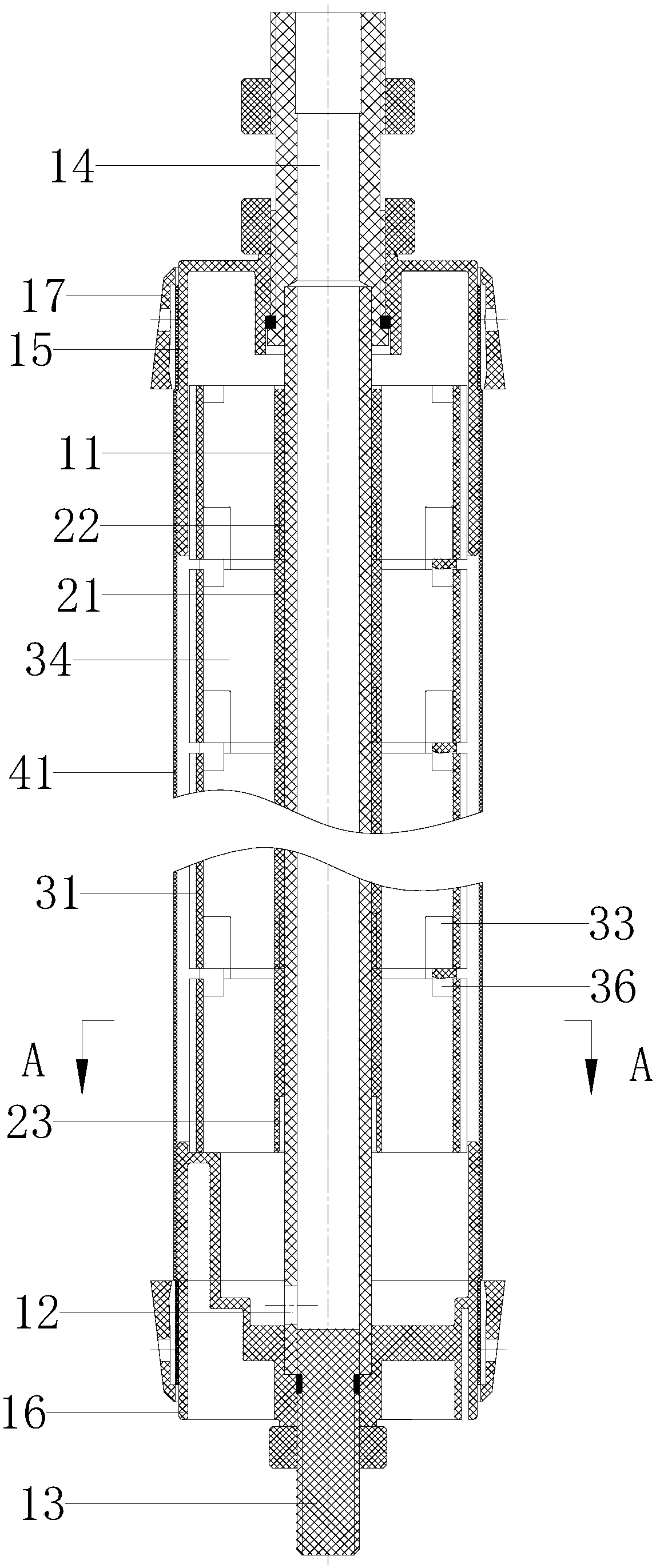

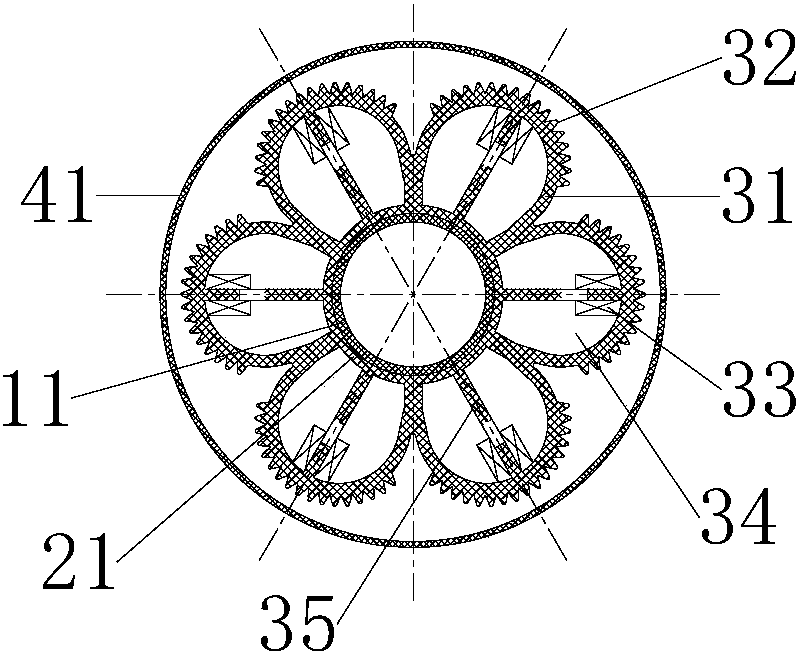

[0038] Such as figure 1 , figure 2 and image 3 As shown, a candle filter element includes an upper end cap 15 , a lower end cap 16 , a central tube 11 , a filter element skeleton 21 , a filter frame 31 and a filter cloth 41 .

[0039] The central pipe 11 is provided with a liquid inlet 12, and the liquid inlet 12 is located at the bottom of the central pipe 11; the bottom of the central pipe 11 is equipped with a lower joint 13 and a lower end cover 16, and the lower joint 13 is located below the liquid inlet 12, and the lower joint 13 blocks the bottom of the central tube 11, the top of the central tube 11 is equipped with an upper connecting pipe 14 and an upper end cover 15, and the upper connecting pipe 14 communicates with the central pipe 11; the filter element skeleton 21 is a round pipe, and a plurality of filter element skeletons 21 are stacked and installed, and the filter element skeleton One end of 21 is provided with inserting ring 22, and the other end is pro...

Embodiment 2

[0056] On the basis of the above embodiments, the outer surface of the filter frame 31 is provided with elongated grooves, the grooves are perpendicular to the axis of the filter core frame 21 , there are no less than two grooves, and the grooves intersect with the protrusions 32 .

[0057] The groove can increase the gap between the filter cloth 41 and the filter frame 31, reduce the contact area between the filter cloth 41 and the filter frame 31, and improve the flow of liquid.

Embodiment 3

[0059] On the basis of the above embodiments, the surface of the filter frame 31 in contact with the filter cloth 41 is provided with through holes. Adding through holes on the filter frame 31 can further reduce the contact area between the filter cloth 41 and the filter frame 31 , maximize the flow of liquid and accelerate the filtration speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com