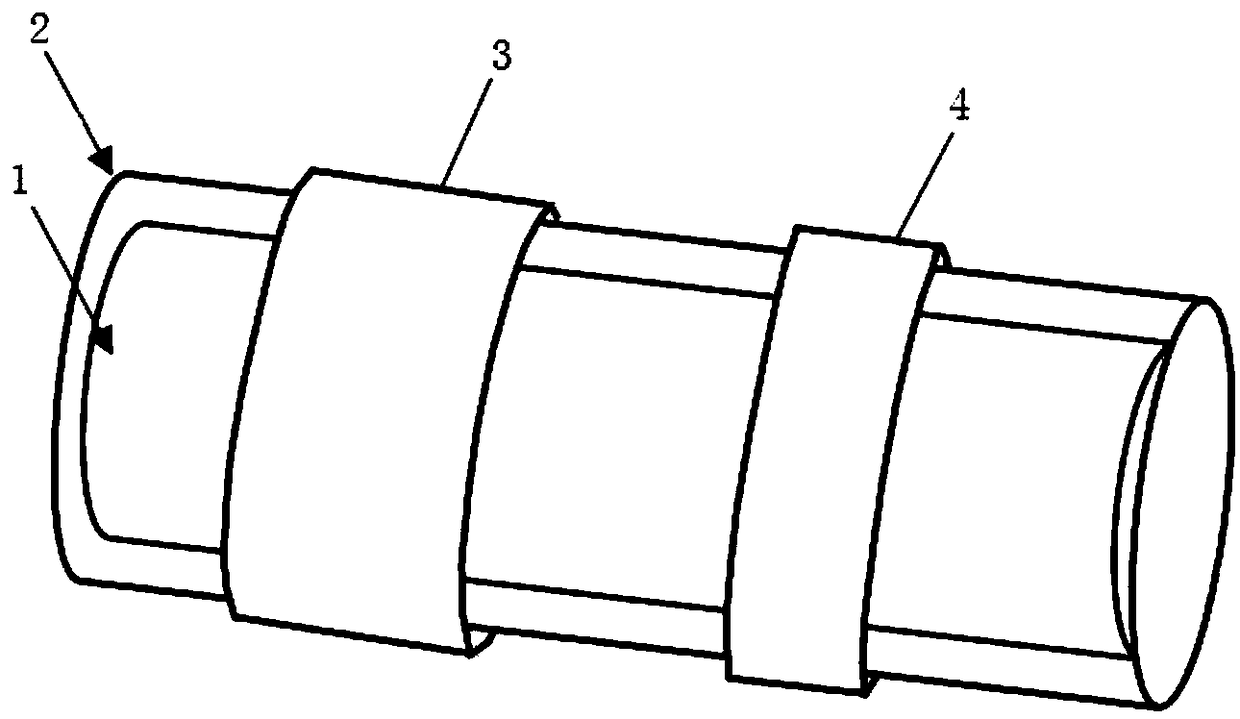

Double-section microwave baking roller and method of the same used for improving baking quality

A microwave baking and drum technology, applied in the application, preparation of tobacco, tobacco, etc., to achieve the effects of low energy consumption, accurate moisture control, and improved quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

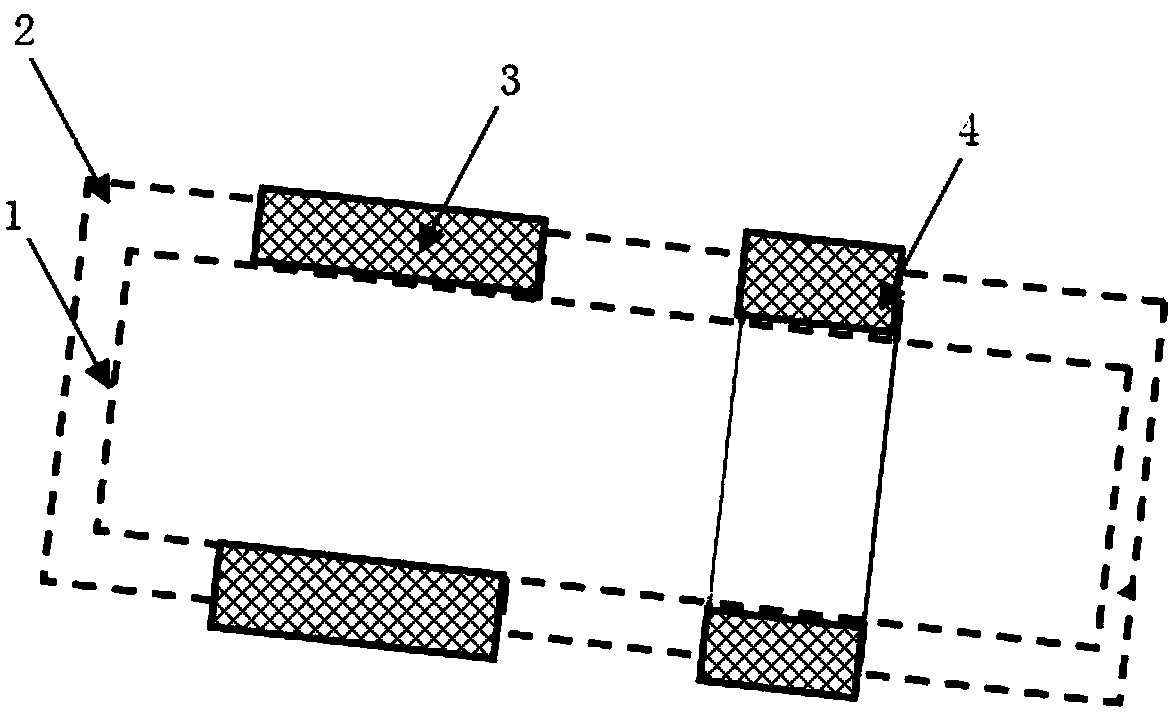

Method used

Image

Examples

Embodiment 1

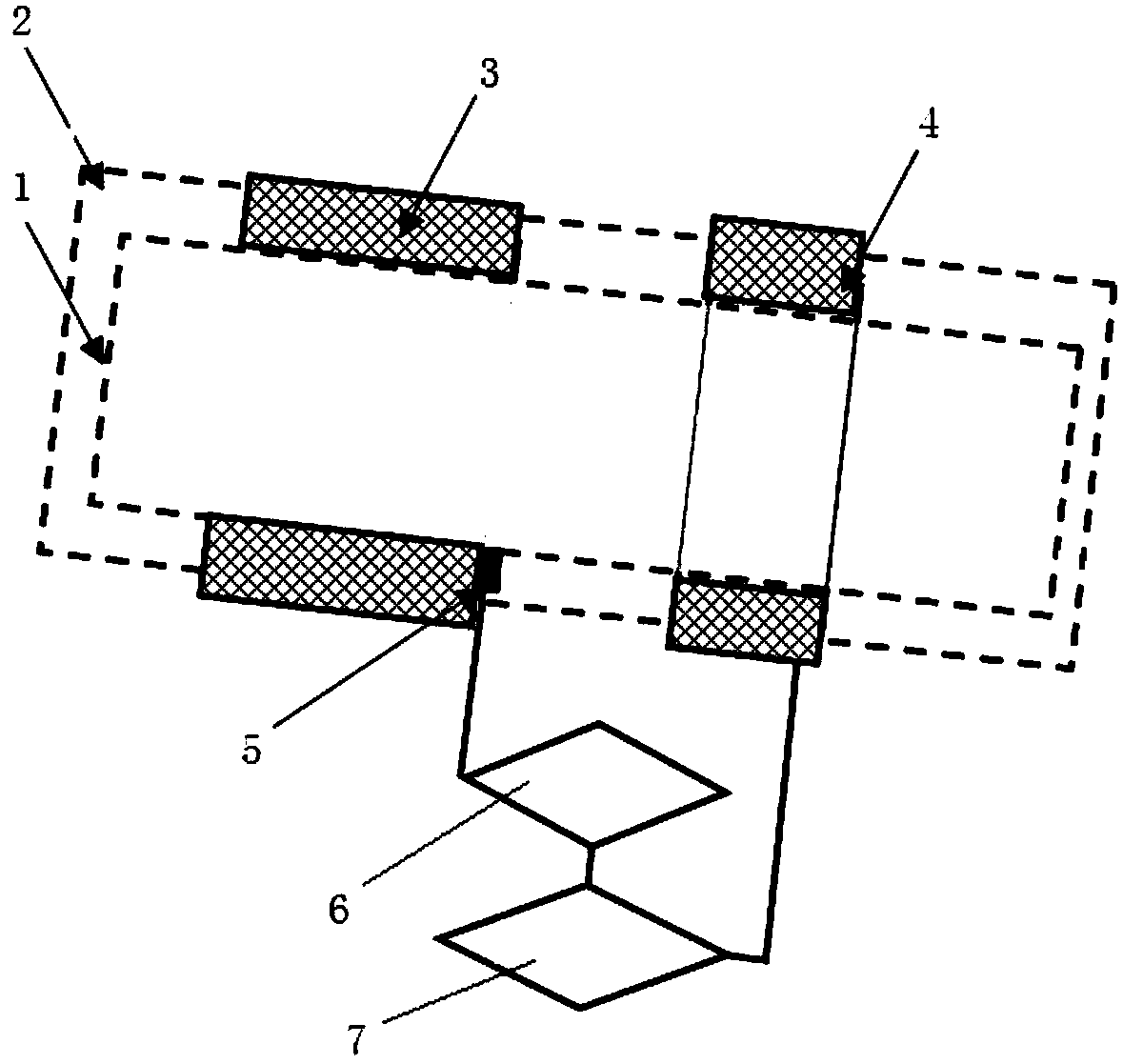

[0027] The double-section microwave drying drum is used for moisture drying of tobacco chips. It adopts low power mode, the moisture content of the incoming material is 15%-18%, the design process flow rate is 500-1000kg / h, and the moisture content of the output material is 12.0%-13.0%. The microwave drying process design of tobacco shreds is as follows: Figure 4 shown. This process is applied to the drying of chips in the process of threshing and redrying.

Embodiment 2

[0029] The silk-making process adopts double-section microwave baking drums to improve the quality of tobacco fragments, adopts high-power mode, the incoming moisture of fragments is 15%-18%, the design process flow rate is 300-600kg / h, and the output is 12.0%--13.0 %. Tobacco chip microwave drying process design such as Figure 5 shown.

Embodiment 3

[0031] The silk-making process adopts double-section microwave baking drums to improve the quality of tobacco fragments. It adopts high-power mode, and the incoming moisture of the fragments is 18%-25%. %--10%, moisture regain after feeding 12.0%--13.0%. Tobacco chip microwave drying process design such as Figure 6 shown.

[0032] The technical effect of the present invention is mainly reflected in the following aspects: using double-section microwave baking equipment to dry or bake the fragments collected during silk making or rebaking, the energy consumption is low, and the moisture content of the outlet fragments is accurately controlled. Tobacco chip quality and quality can be significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com