Five grain and coarse cereal powder and manufacture method thereof

A technology of whole grains and preparation method, applied in food processing, food science, application and other directions, can solve the problems of poor water solubility, low nutrient absorption rate, lack of scientificity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

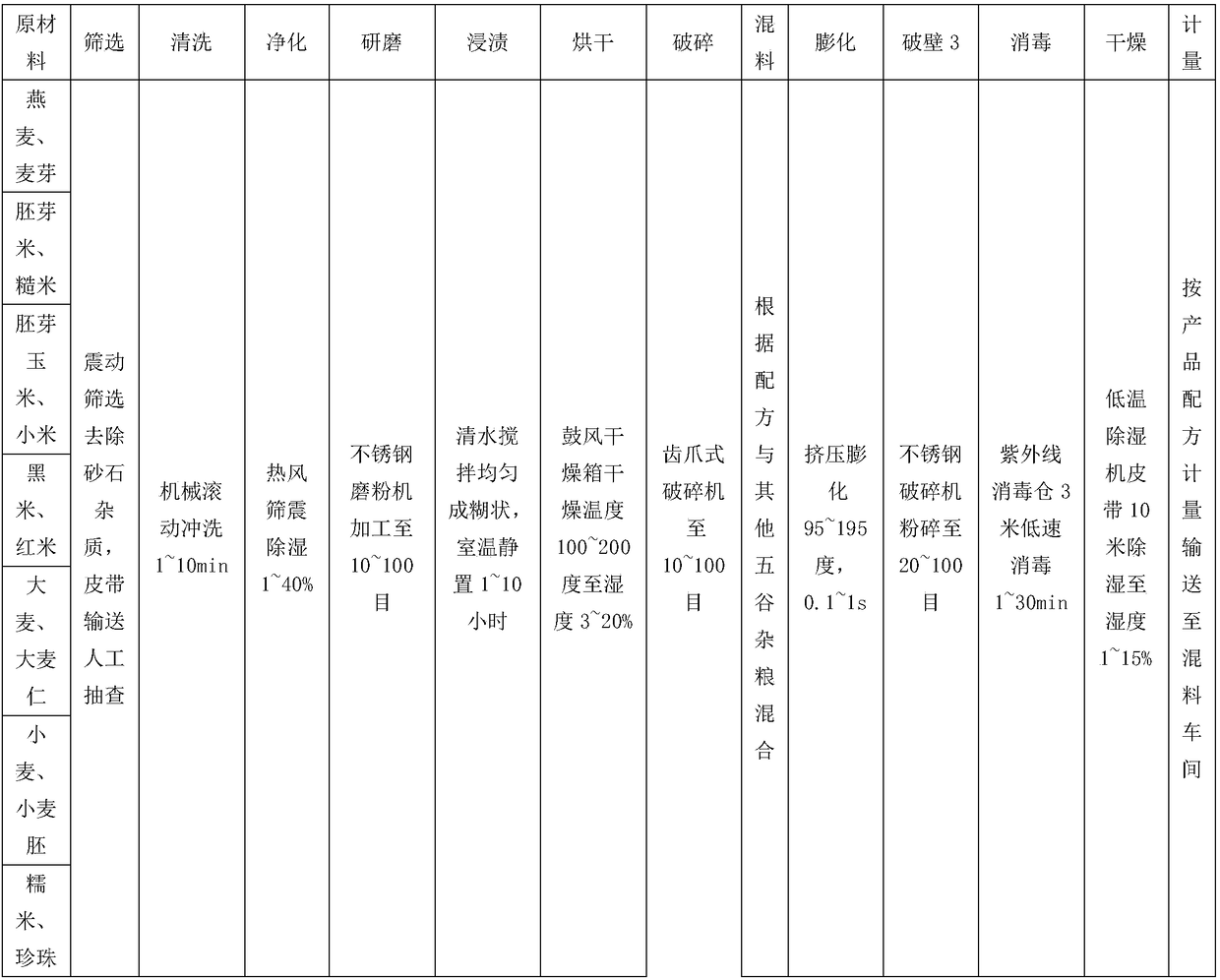

Method used

Image

Examples

Embodiment 1

[0113] Whole grains powder, including base material and compatible material, the base material includes the following raw materials in parts by mass: 20 parts of iron stick yam, 25 parts of Huai yam, 29 parts of bergamot yam, 19 parts of purple jade yam, 22 parts of Huai yam, Ganoderma lucidum 36 parts of yam, 21 parts of oats, 20 parts of germ rice, 22 parts of corn germ, 31 parts of maltodextrin, 42 parts of non-dairy creamer, 3.2 parts of ethyl maltol, 6 parts of sodium carboxymethylcellulose, 7 parts of konjac powder ;

[0114]The compatible material includes the following raw materials in parts by mass: 20 parts of red bean, 18 parts of coix seed, 20 parts of walnut, 17 parts of black sesame, 6 parts of ginseng, 6 parts of wolfberry, 6 parts of donkey-hide gelatin, 2 parts of sweet almond, 3 parts of kudzu root, 2 parts of ginkgo, 5 parts of bitter melon, 8 parts of seabuckthorn, 4 parts of raspberry, 11 parts of brown rice, 11 parts of millet, 11 parts of black rice, 12 ...

Embodiment 2

[0116] Cereal powder, including base material and compatible material, the base material includes the following raw materials in parts by mass: 3 parts of iron stick yam, 3 parts of Huaishan yam, 0.2 part of bergamot yam, 0.3 part of purple jade yam, 0.3 part of Huaishan yam, Ganoderma lucidum 0.2 parts of yam, 0.5 parts of oats, 5 parts of germ rice, 1 part of corn germ, 5 parts of maltodextrin, 5 parts of non-dairy creamer, 0.1 part of ethyl maltol, 1.2 parts of sodium carboxymethylcellulose, 0.3 parts of konjac powder ;

[0117] The compatibility material includes the following raw materials in parts by mass: 1 part of red bean, 0.5 part of coix seed, 2 parts of walnut, 2 parts of black sesame, 2 parts of ginseng, 2 parts of wolfberry, 2 parts of donkey-hide gelatin, 0.1 part of bitter almond, 0.2 part of kudzu root, 0.3 part of ginkgo, 0.1 part of bitter melon, 0.1 part of seabuckthorn, 0.1 part of raspberry, 0.1 part of brown rice, 0.1 part of millet, 0.1 part of black ri...

Embodiment 3

[0119] Whole grains powder, including base materials and compatible materials, the base materials include the following raw materials in parts by mass: 38 parts of iron stick yam, 40 parts of Huai yam, 35 parts of bergamot yam, 25 parts of purple jade yam, 35 parts of Chinese yam, Ganoderma lucidum 50 parts of yam, 25 parts of oats, 25 parts of germ rice, 25 parts of corn germ, 35 parts of maltodextrin, 50 parts of non-dairy creamer, 5 parts of ethyl maltol, 10 parts of sodium carboxymethyl cellulose, 10 parts of konjac powder ;

[0120] The compatibility material includes the following raw materials in parts by mass: 25 parts of red bean, 25 parts of coix seed, 25 parts of walnut, 25 parts of black sesame, 8 parts of ginseng, 10 parts of wolfberry, 10 parts of donkey-hide gelatin, 0-10 parts of sweet almond, 10 parts of kudzu root 10 parts of ginkgo, 10 parts of bitter melon, 10 parts of seabuckthorn, 10 parts of raspberry, 15 parts of brown rice, 15 parts of millet, 15 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com