Sterilization method of germination bacteriostatic agent

A sterilization method and bacteriostatic agent technology, applied in the directions of Streptococcus/Lactococcus, bacteria used in food preparation, food science, etc. Industrial production application, improve sterilization efficiency, improve the effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

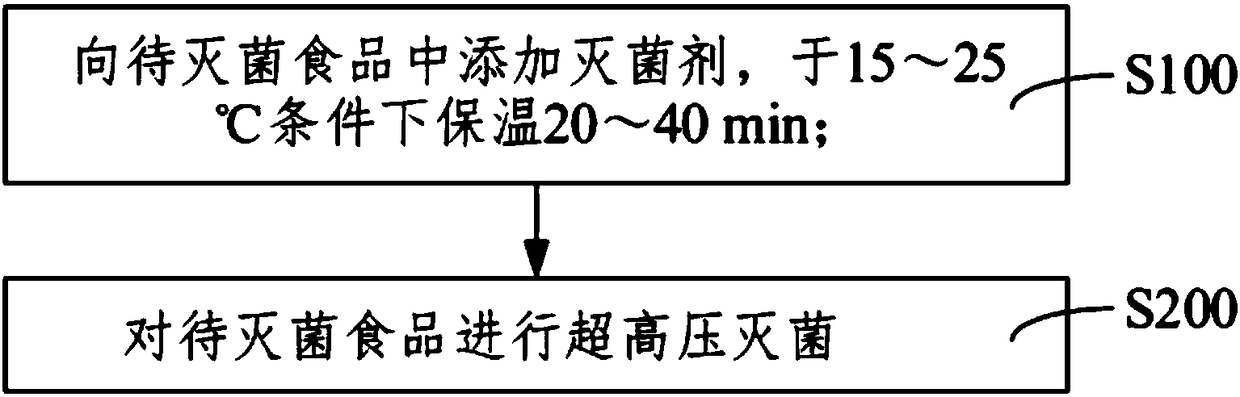

Method used

Image

Examples

Embodiment 1

[0048] Thaw 55kg of quick-frozen strawberries and 15kg of sugar; dissolve 2.5kg of modified starch, 0.5kg of pectin, and 6.6kg of white sugar in 20kg of water. Stir for 6 minutes under the same conditions to prepare strawberry jam.

[0049] 0.4kg of L-alanine was mixed with 0.03kg of nisin to prepare a germination inhibitor. Add 0.43kg of the above-mentioned germination inhibitor to the strawberry jam, stir evenly, keep warm at 20°C for 30min, and pack.

[0050] Put the packaged strawberry jam into an autoclave, sterilize it under normal temperature with a pressure of 550MPa for 5 minutes, release the pressure, and store it in cold storage.

Embodiment 2

[0055] Thaw 55kg of quick-frozen raspberries and 14kg of sugar; dissolve 3.0kg of modified starch, 0.5kg of pectin, and 9kg of white sugar in 18kg of water. Stirring for 10 minutes under the same conditions to prepare raspberry jam.

[0056] 0.5 kg of L-alanine was mixed with 0.06 kg of nisin to prepare a germination inhibitor. Add 0.56kg of the above-mentioned germination inhibitor to the raspberry jam, stir evenly, keep warm at 20°C for 40min, and pack.

[0057] Put the packaged raspberry jam into an autoclave, and sterilize it at a pressure of 600MPa for 3 minutes at room temperature, then release the pressure and store it in refrigeration.

Embodiment 3

[0062] Thaw 55kg of quick-frozen raspberries and 14kg of sugar; dissolve 3.0kg of modified starch, 0.5kg of pectin, and 9kg of white sugar in 18kg of water. Stirring for 10 minutes under the same conditions to prepare raspberry jam.

[0063] 0.2kg of L-alanine was mixed with 0.02kg of nisin to prepare a germination inhibitor. Add 0.22kg of the above-mentioned germination inhibitor to the raspberry jam, stir evenly, keep warm at 25°C for 20min, and pack.

[0064] Put the packaged raspberry jam into an autoclave, sterilize it at room temperature with a pressure of 450 MPa for 10 minutes, then release the pressure and store it in refrigeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com