Flexible optical fiber composite submarine cable and preparation method thereof

An optical fiber composite, submarine cable technology, applied in the direction of submarine cables, insulated cables, communication cables, etc., can solve the problems of heavy weight, inconvenience, increased cost, etc., achieve low eddy current loss and hysteresis loss, high transmission efficiency, high resistance The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

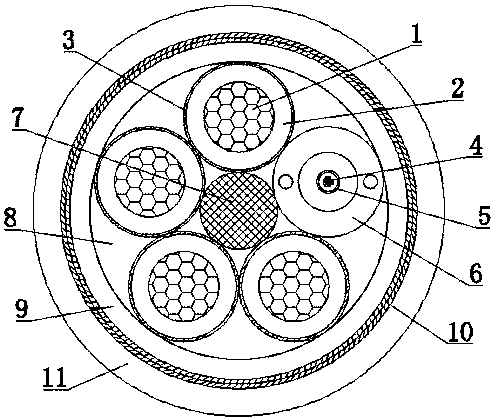

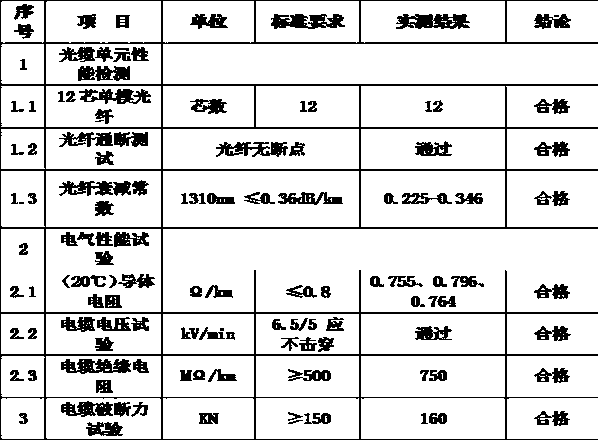

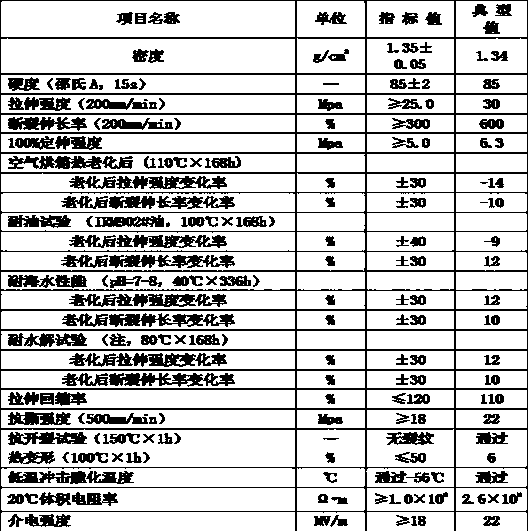

[0024] A flexible optical fiber composite submarine cable, including four power cable cores in the middle, a communication optical cable, and an aramid fiber reinforcing rib 7, and a polyurethane filling layer 8 on the outer layer, an inner sheath layer 9, and an aramid braiding layer 10 and a polyurethane outer sheath 11, the aramid ribs 7 are arranged at the center of the annular circle formed by the four power cable cores and a communication optical cable, and the power cable cores include sequentially from the inside to the outside The fifth category oxygen-free copper flexible conductor 1, nitrile-PVC composite insulation layer 2 and copper wire braided shielding layer 3, the fifth category oxygen-free copper flexible conductor 1 is made of multiple tinned annealed soft copper wire twisted The communication optical cable is provided with a twelve-core optical fiber 4 inside, and the outer layer of the twelve-core optical fiber 4 is sequentially provided with a stainless st...

Embodiment 2

[0041] A kind of preparation method of flexible optical fiber composite submarine cable

[0042] Twist 28 thin round oxygen-free copper wire bundles of 0.4mm into 2.57mm strands with a stranding machine, and then twist 7 strands into a round conductor with an outer diameter of 7.7mm in a 1+6 structure through a frame stranding machine.

[0043] A 120-type extruder is used to extrude 2.2mm nitrile-PVC compound insulation on a 7.7mm round conductor with an extrusion die to obtain 4 insulated wire cores of 12.1mm.

[0044] On the outside of the insulated core, braid the metal shield using a braiding machine. The metal shielding layer is braided with 160 0.2mm copper wires, the braiding density is 57.6%, and the outer diameter after braiding is 12.9mm.

[0045] The high-tensile-strength aramid ribs filled in the middle are made of 42 aramid fiber bundles twisted into 3.1mm strands, and then 7 strands are twisted into 9.3mm aramid ribs in a 1+6 structure.

[0046] 4 insulated cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com