Tooth-shaped rotor set

A rotor set and rotor technology, applied in the field of rotor sets, can solve the problems of uneven force, thin tooth blades, and inability to use high-strength shafts, so as to reduce leakage and increase pressure gradient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0014] The object of the present invention is to provide a toothed rotor group which can increase the pressure gradient to reduce leakage.

[0015] Another object of the present invention is to provide a toothed rotor assembly that can use a high-strength shaft.

[0016] Another object of the present invention is to provide a toothed rotor set suitable for high pressure difference and high pressure ratio mechanical facilities.

[0017] Another object of the present invention is to provide a toothed rotor set that can make the force close to facilitate the selection of bearings.

[0018] Another object of the present invention is to provide a toothed rotor assembly that can improve machining accuracy.

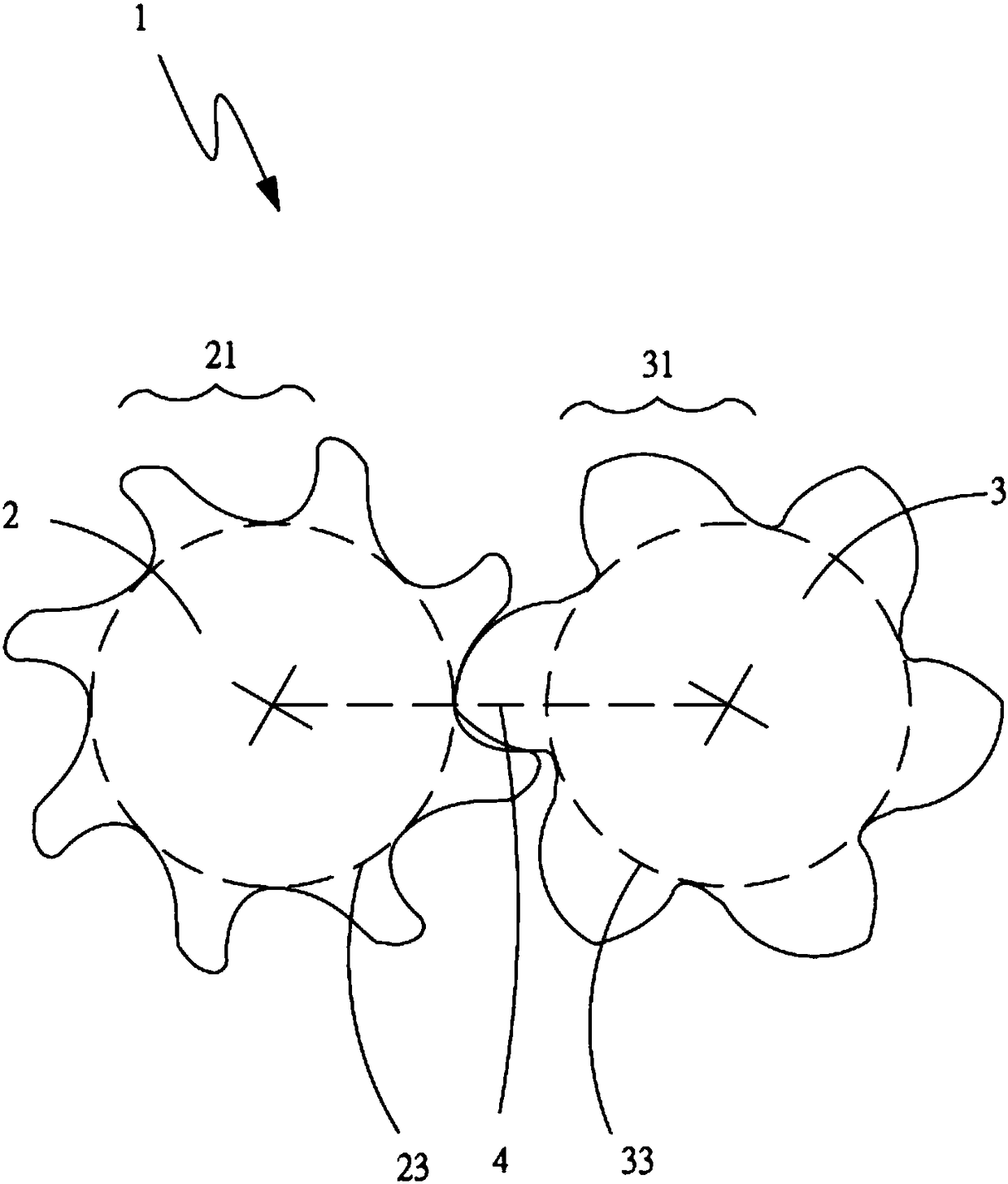

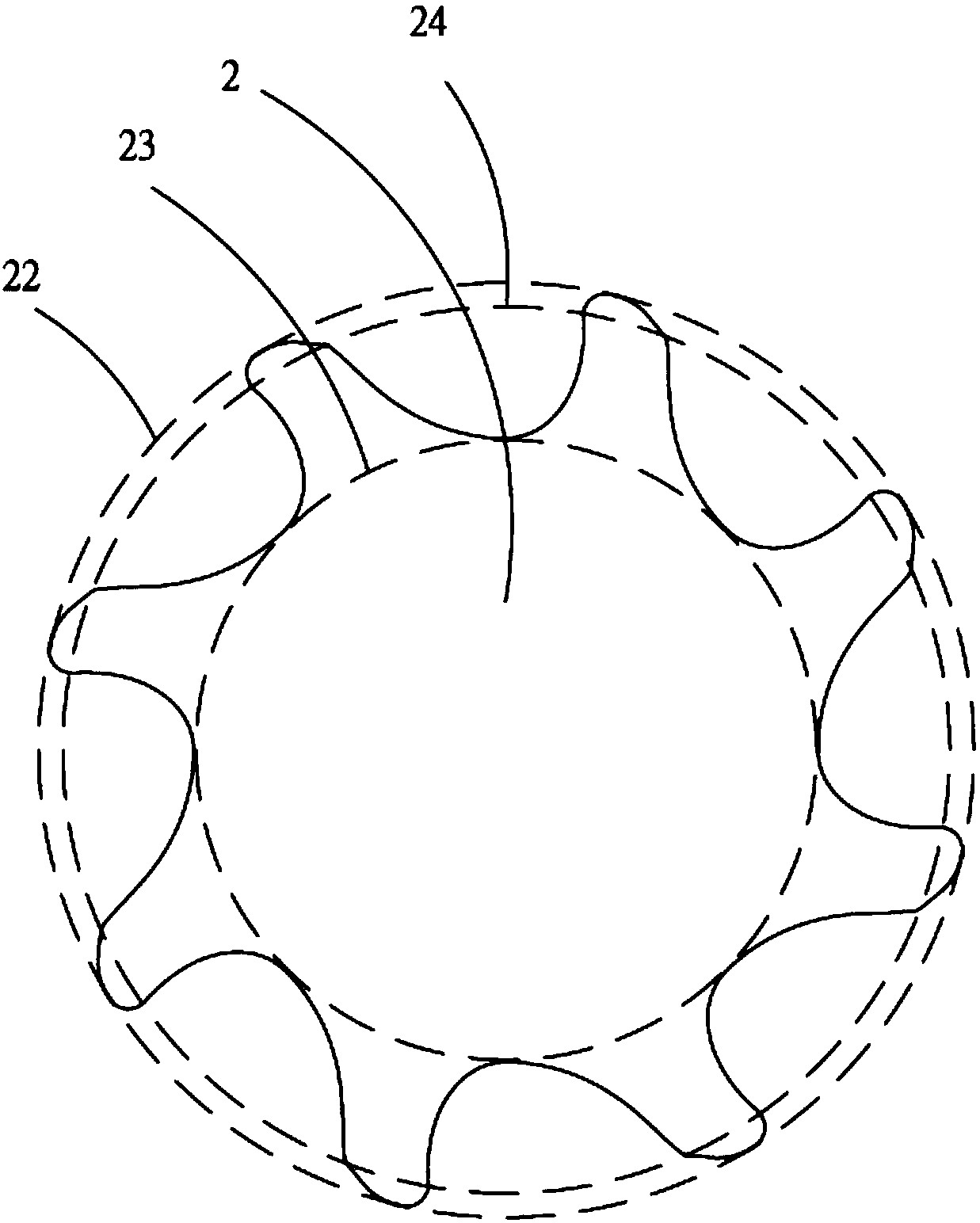

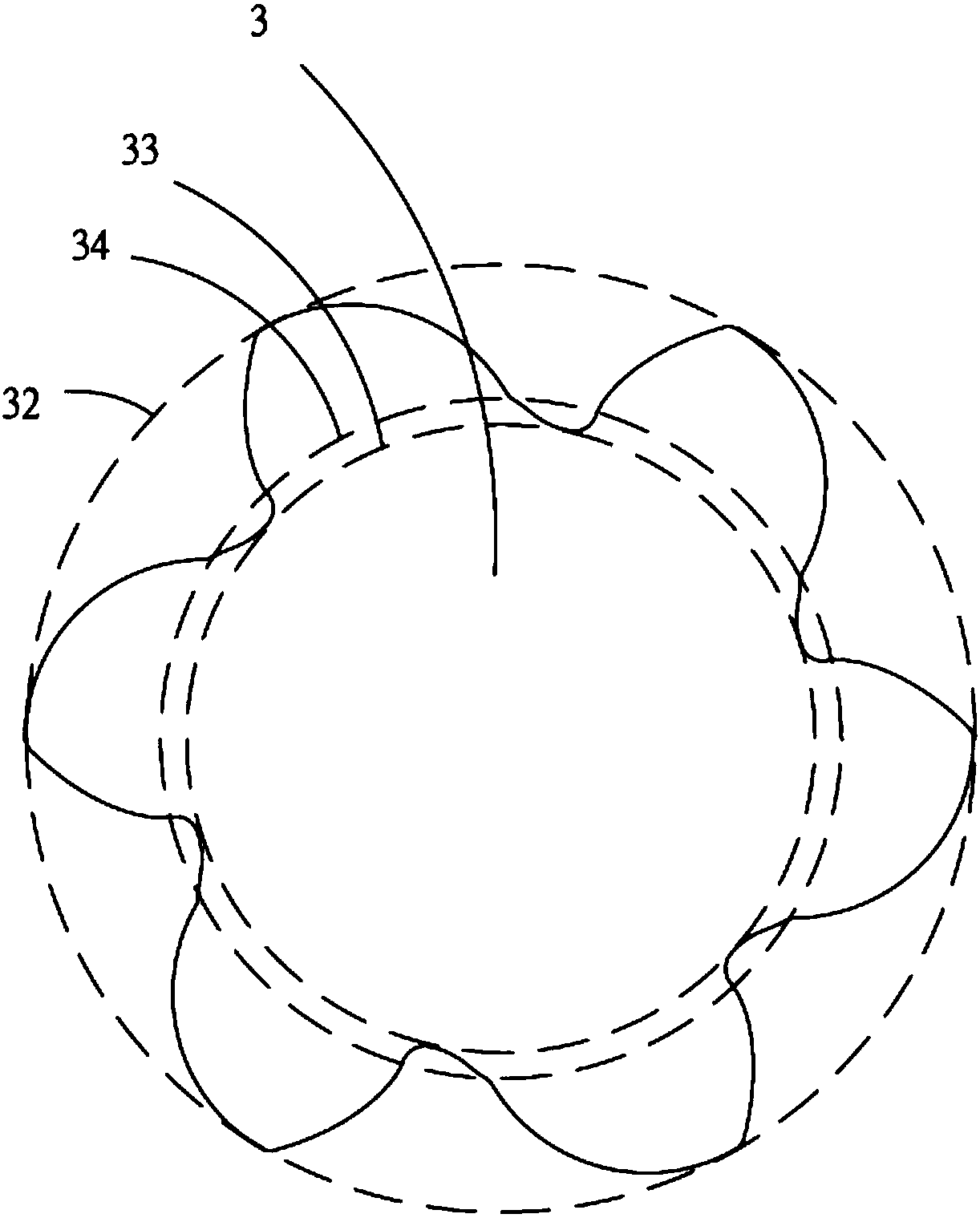

[0019] In order to achieve the above purpose, the present invention provides a toothed rotor set, including: a female rotor and a male rotor, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com