An effective volume fracturing method for shale with high clay content

A technology with effective volume and high clay, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of high construction pressure, low volume of stimulation, increasing the effective volume of stimulation of shale with high clay content, etc. , to achieve the effect of increasing net pressure, promoting full extension, and increasing intercluster stress interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

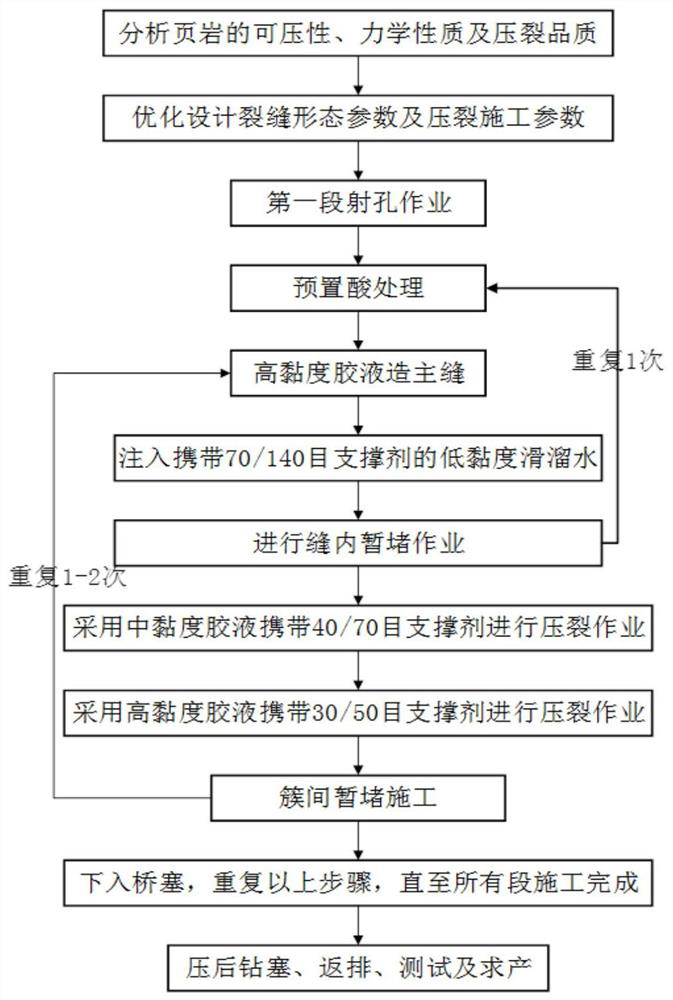

Image

Examples

Embodiment 1

[0085] A continental shale gas well has a depth of 4013 m, a bathymetry of 5229 m, and a horizontal section length of 1200 m. After the core of the guide eye well and the data analysis of logging, it was found that the clay content of the high-quality shale section of the well was relatively high, reaching more than 50%. To increase production per well, retrofits are performed as follows:

[0086] (1) Based on ECLIPSE, a commonly used commercial simulation software for fracturing production forecasting, and MEYEY, a commonly used commercial simulation software for crack propagation simulation, the optimal fracturing section is determined to be 17 segments based on the simulation optimization of the conventional process, and the scale of single-stage fracturing fluid is 2200m 3 The single-stage sand volume scale is 65m 3 There are 4 clusters in a single section, with a perforation length of 0.75m and a perforation density of 16 wells / m perforated.

[0087] (2) After the first stage...

Embodiment 2

[0101] A continental shale gas well has a depth of 3908 m, a bathymetry of 4213 m, and a horizontal section length of 1400 m. After the core of the guide eye well and the data analysis of logging, it was found that the clay content of the high-quality shale section of the well was relatively high, reaching more than 60%. To increase production per well, retrofits are performed as follows:

[0102] (1) Based on ECLIPSE, a commonly used commercial simulation software for fracturing production forecasting, and MEYEY, a commonly used commercial simulation software for crack propagation simulation, the optimal fracturing section is determined to be 17 segments based on the simulation optimization of the conventional process, and the scale of single-stage fracturing fluid is 2200m 3 The single-stage sand volume scale is 65m 3 There are 8 clusters in a single section, with a perforation length of 0.5 m and a perforation density of 16 wells / m per cluster.

[0103] (2) After completing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com