Steel structure column for building technology services

A technical service and steel structure technology, applied in the field of steel structure columns for building technical services, can solve problems such as poor fire resistance of steel structures, and achieve the effect of improving stability and avoiding building deformation and collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

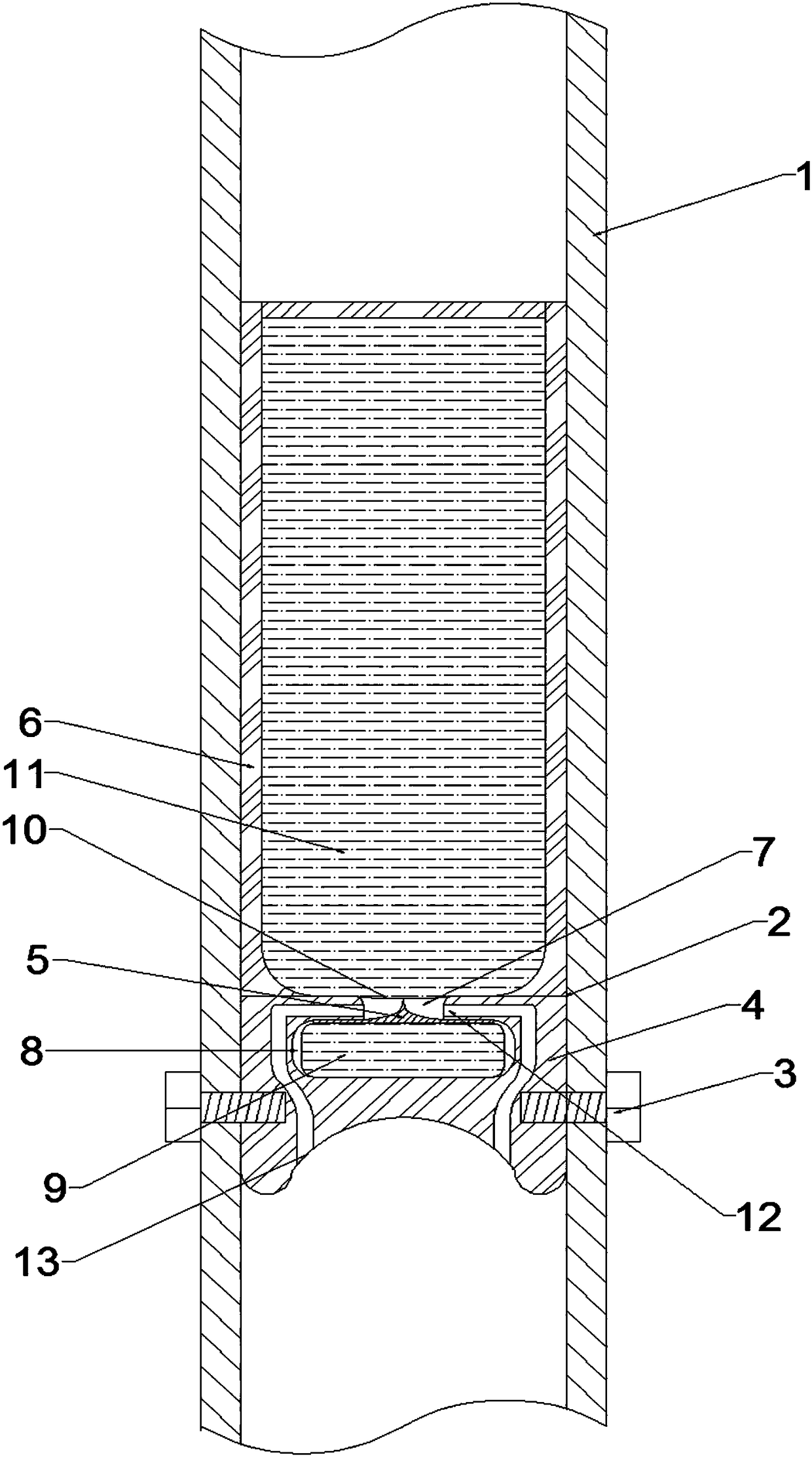

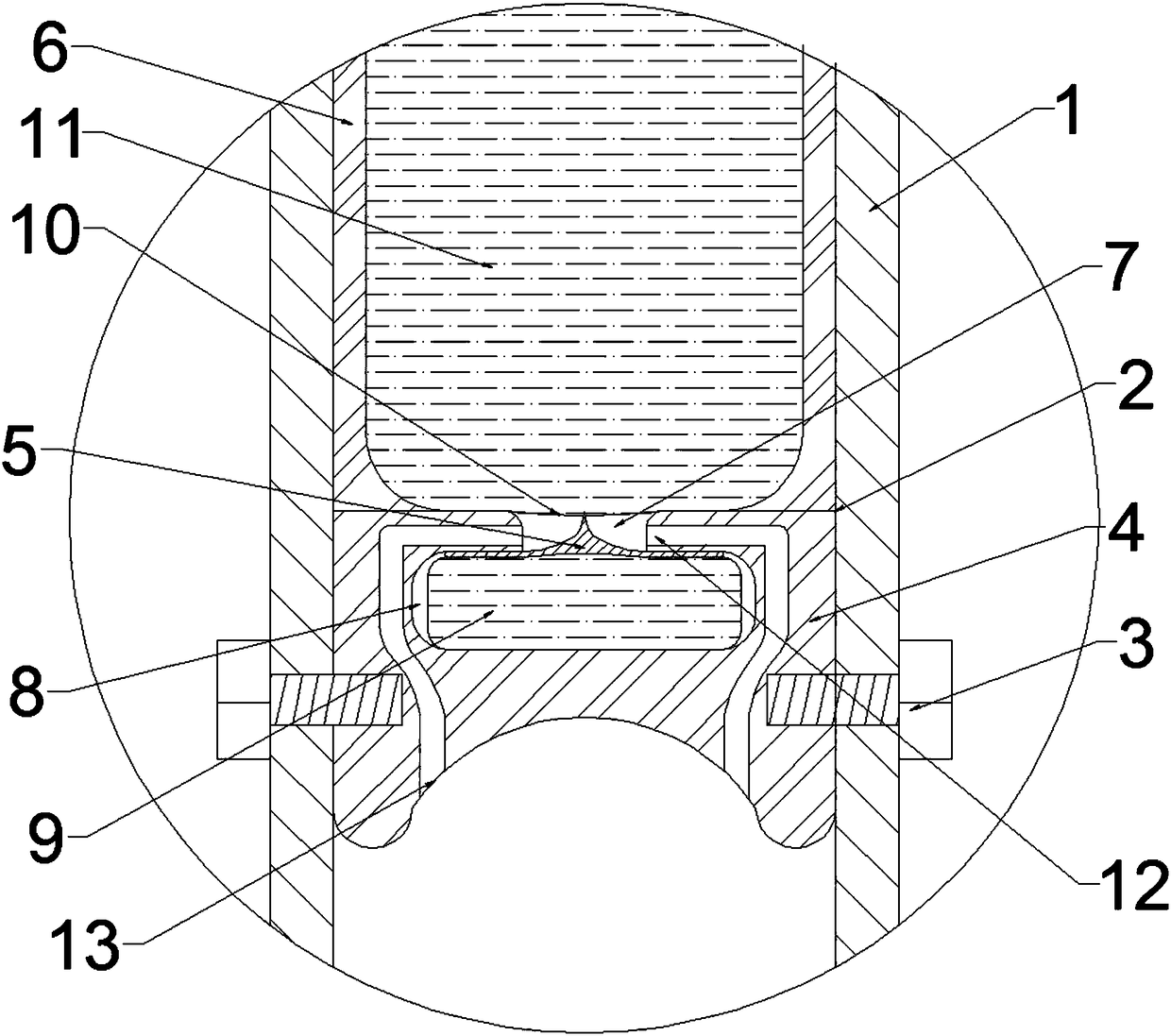

[0020] Embodiment 1: When using a steel structure column for building technology service to build a building, a steel structure column for building technology service includes a column 1 and a cooling device 2, and the inside of the column 1 is fixedly connected with a plurality of cooling devices 2 through bolts 3, The cooling device 2 includes a base 4, a puncture needle 5, and a water storage chamber 6. The upper surface of the base 4 is fixed with a puncture hole 7, and the inside of the base 4 is fixed with a puncture chamber 8 corresponding to the puncture hole 7, and a water bag 9 is fixedly connected to the puncture chamber 8. The upper surface of the water bag 9 is located inside the puncture chamber 8 and is movably connected with the puncture needle 5, the upper surface of the base 4 is fixedly connected to the water storage chamber 6, the inner wall of the water storage chamber 6 is fixedly connected to the water-proof membrane 10, and the water bag 9 and the water-p...

Embodiment 2

[0023] Embodiment 2: When not in use, a steel structure column for architectural technical services includes a column 1 and a cooling device 2. A plurality of cooling devices 2 are fixedly connected to the inside of the column 1 through bolts 3. The cooling device 2 includes a base 4 and a puncture needle. 5 and the water storage chamber 6, the upper surface of the base 4 is fixedly provided with a puncture hole 7, and the interior of the base 4 is fixedly provided with a puncture chamber 8 corresponding to the puncture hole 7, and a water bag 9 is fixedly connected to the puncture chamber 8, and the upper surface of the water bag 9 is located at the puncture chamber 8 The interior is movably connected with a puncture needle 5, the upper surface of the base 4 is fixedly connected to the water storage bin 6, the inner wall of the water storage bin 6 is fixedly connected to the water-proof membrane 10, the water bag 9 and the water-proof membrane 10 are filled with a cooling liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com