A curved multi-angle array jet nozzle and its application

A technology of array jets and jet nozzles, applied in furnaces, furnace types, heat treatment equipment, etc., to achieve the effect of improving heat exchange efficiency and uniformity, improving heat exchange efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides an operation technical solution when the arc surface multi-angle array jet nozzle sprays water to quench the steel plate with a width greater than or equal to the length of the middle section.

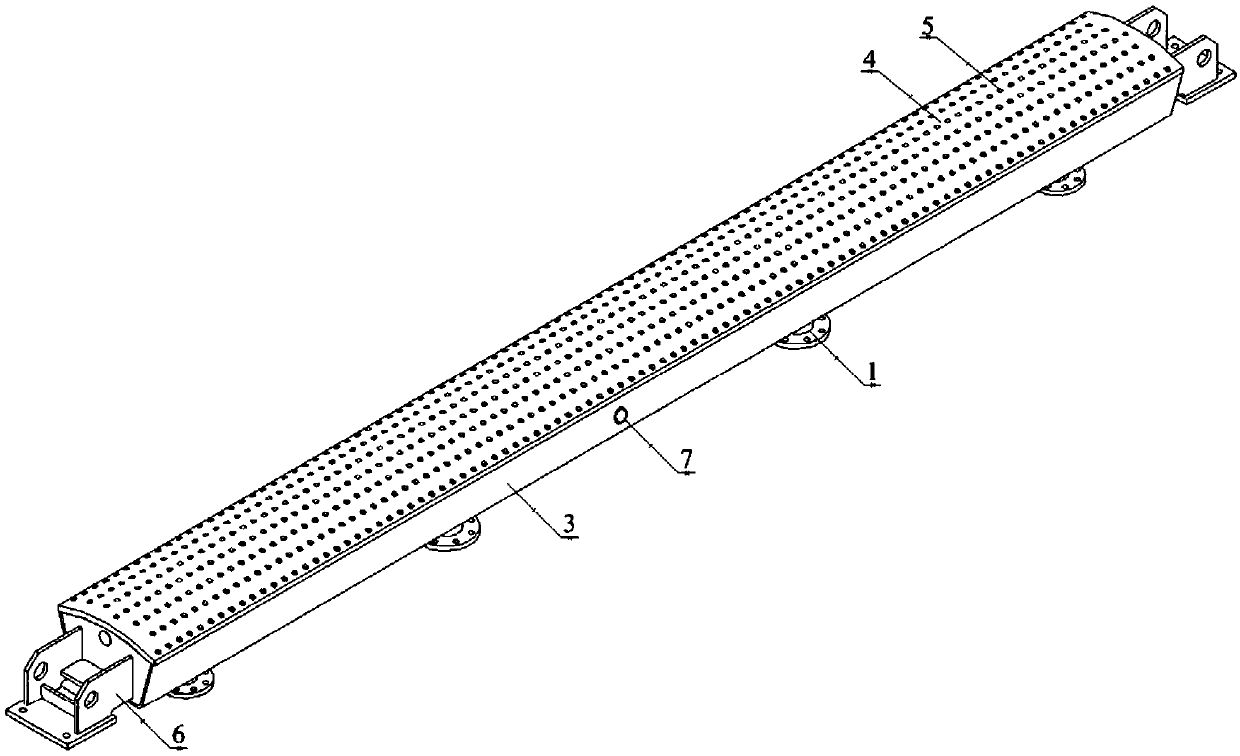

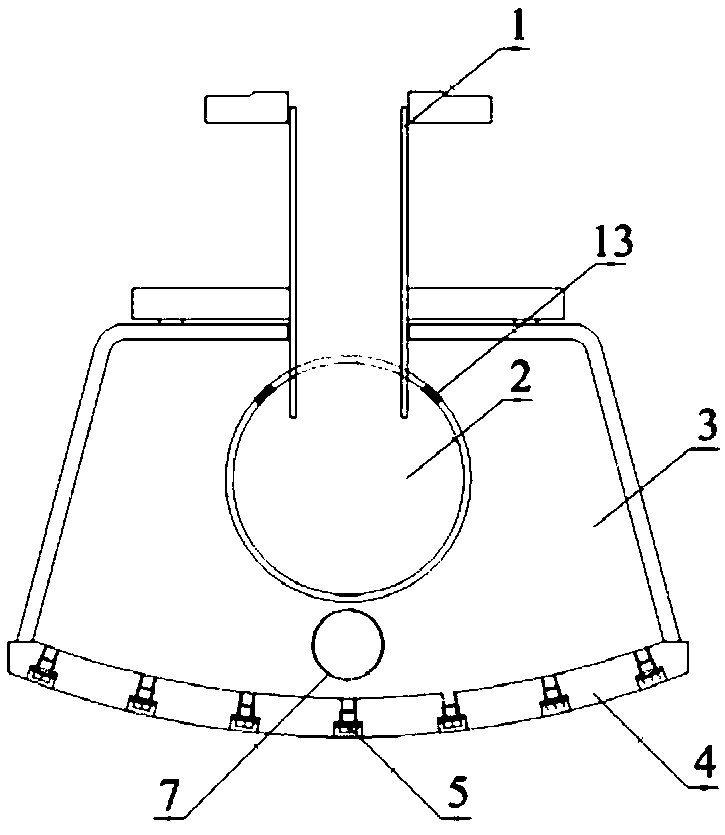

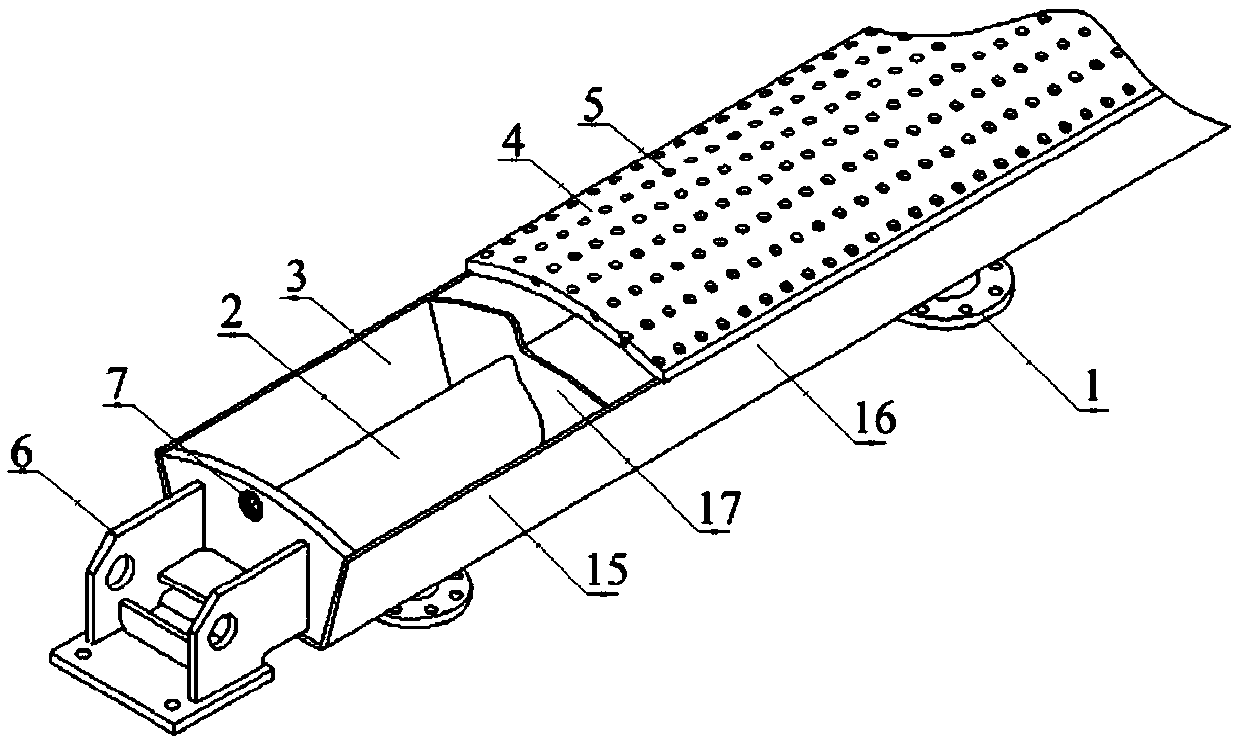

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, before the steel plate (8) enters the low-pressure section of the roller quenching machine, the cooling water with a pressure of 0.2-0.5 MPa flows through the water inlet interface (1) of the middle section (16) and the two side sections (15) respectively according to the process setting flow rate. The water inlet port (1) of the middle section (16) and the water equalization chamber (2) of the two side sections (15) are respectively injected into the water equalization chamber (2) of the two side sections (15). After the water equalization chamber (2) is filled with water, two rows of equalization holes (13) Inject into the outer water collection chamber (3), and the pressurized coo...

Embodiment 2

[0038] This embodiment provides a technical solution for dismantling and installing the arc-surface multi-angle array jet nozzle.

[0039] Such as figure 1 , Figure 4 As shown, before disassembling the jet nozzle, close all manual maintenance valves in the low-pressure section of the roller quenching machine, and the control valve group of the water supply pipeline is in a power-off state. When disassembling the upper nozzle (11), transport the steel plate (8) reversely from the outlet of the low pressure section of the roller quenching machine to the upper nozzle (11) to be disassembled, and loosen the fastening mechanism (6) on both sides of the upper nozzle (11). The fastening bolts and the water inlet port (1) of the upper nozzle (11) are connected to the flange fastening bolts, and the upper nozzle (11) is placed on the steel plate (8), and the steel plate (8) carries the upper nozzle (11) by a roller The exit of the low-pressure section of the quenching machine drives...

Embodiment 3

[0041] This embodiment provides a technical solution for unclogging operation of arc-surface multi-angle array jet nozzles.

[0042] Such as figure 1 As shown, first dredge the small nozzle (5) water spray holes embedded in the curved panel (4) one by one with a metal rod with a diameter slightly smaller than the small nozzle (5) water spray hole, to ensure that there is no water spray in the small nozzle (5) water spray hole. foreign body. Afterwards, open the drain hole (7) on the end face of the water collection chamber (3) of the two side sections (15) of the nozzle and the drain hole (7) on the outer wall of the water collection chamber (3) of the middle section (16), by two The water inlet port (1) of the side section (15) is respectively injected with a flow rate of 30-50m 3 / h, cooling water with a pressure of 0.1MPa, injected from the water inlet port (1) of the middle section (16) with a flow rate of 60-100m 3 / h, and cooling water with a pressure of 0.1MPa, rinse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com