Automatic processing equipment for sanitary water pipe

A technology for processing equipment and water pipes, which is applied in the field of automatic processing equipment for sanitary water pipes, can solve the problems of reduced production efficiency, unsteady installation, and failure to meet the use requirements, and achieve the effects of reducing production efficiency, enhancing efficiency, and meeting use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

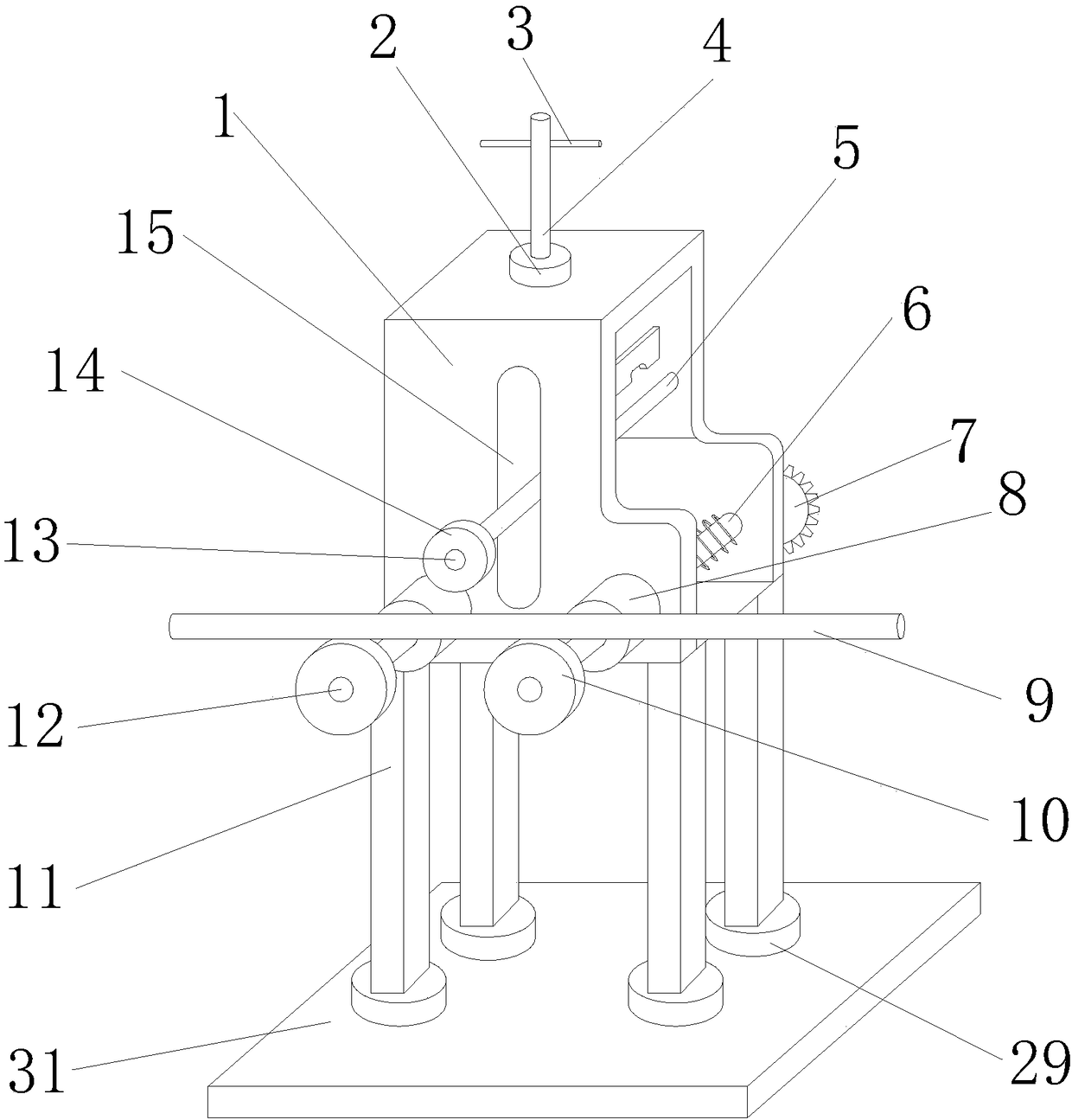

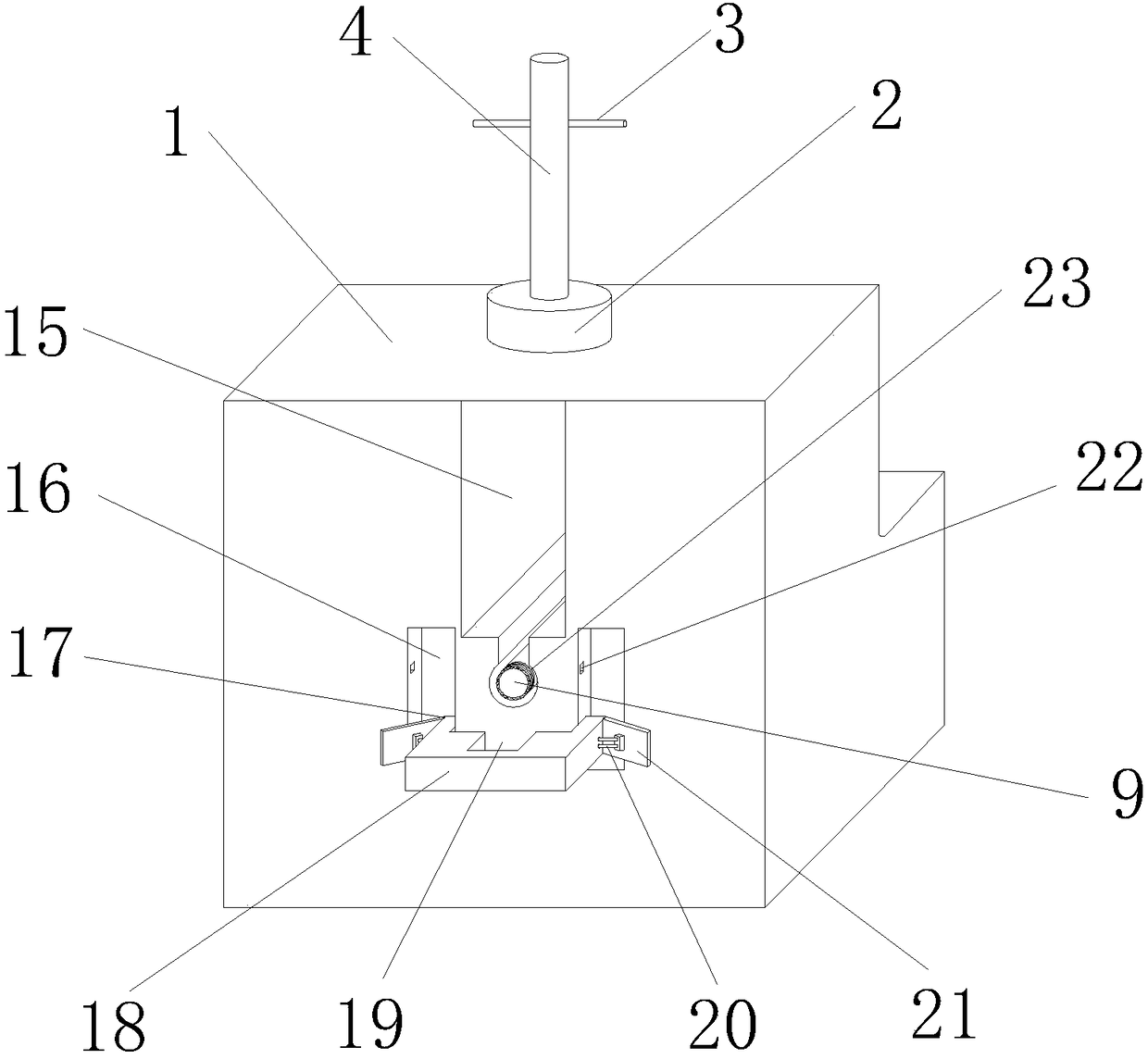

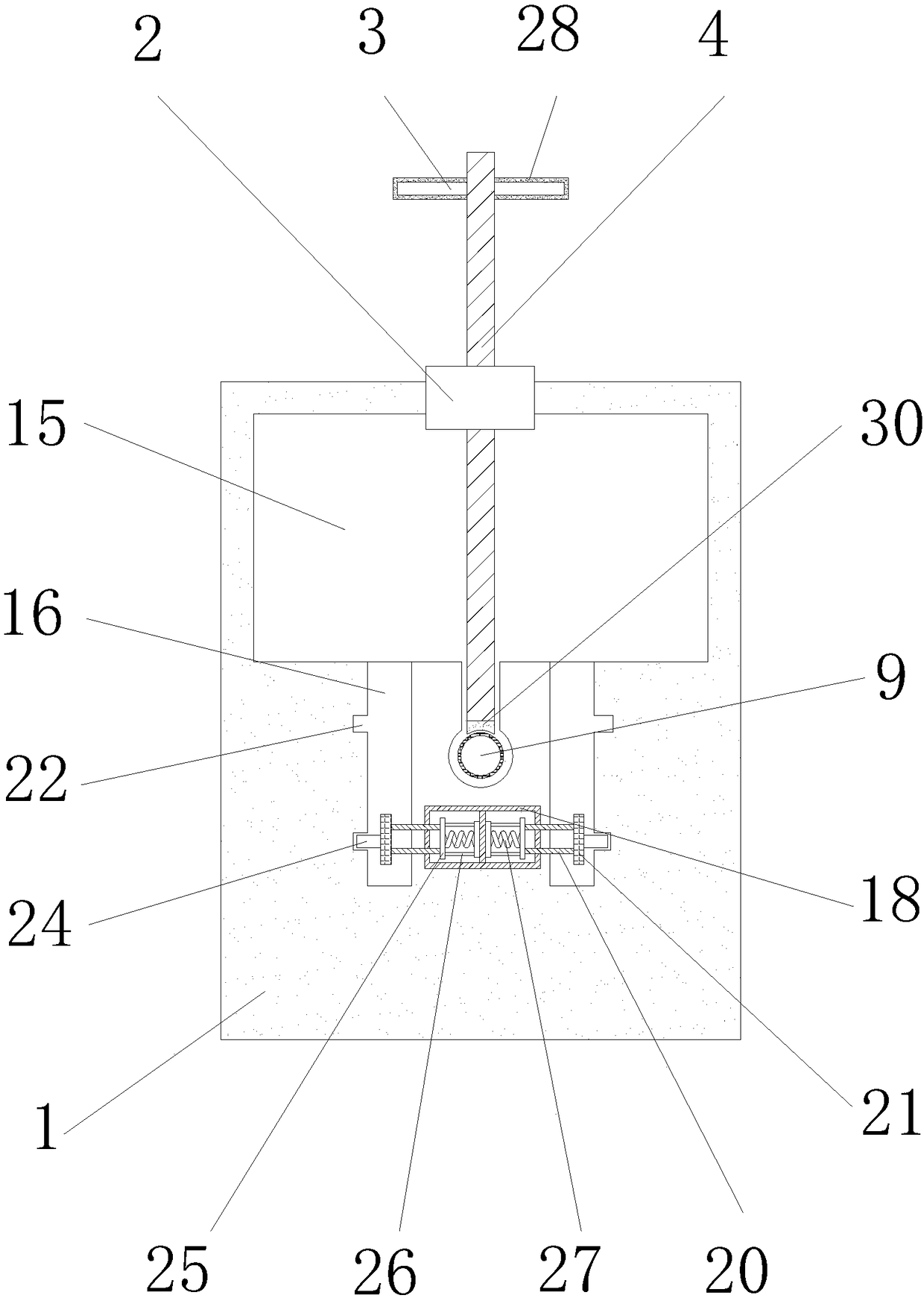

[0018] see Figure 1-3 , the present invention provides a technical solution: an automatic processing equipment for bathroom water pipes, including a body 1, the body 1 is used to fix the connecting block 2, the bottom end of the body 1 is equipped with a connecting block 2, and the connecting block 2 is used to fix the rotating rod 4 , the bottom end of the connecting block 2 is provided with a rotating rod 4, the rotating rod 4 rotates to fix the water pipe 9, the bottom end of the rotating rod 4 is equipped with a plastic pad 30, and the plastic pad 30 is used to increase the friction between the rotating rod 4 and the water pipe 9 , the top of the outer wall of the rotating rod 4 is equipped with a handle 3, the handle 3 is used to drive the rotating rod 4 to rotate, the outer wall of the handle 3 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com