Automatic processing method and equipment for small-diameter copper pipe with inner and outer cones and thin-walled circles

An automatic processing and thin-walled technology, which is applied in the field of small-diameter copper pipe processing devices, can solve the problems of uneven wall thickness, short service life, and large axial resistance, and achieve improved wall thickness uniformity, convenient operation, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

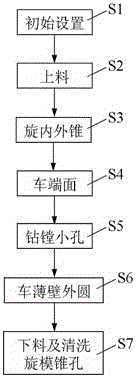

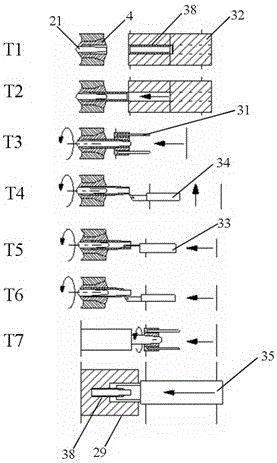

[0057] The automatic processing method and equipment of small-diameter copper pipes with inner and outer cones and thin-walled circles of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

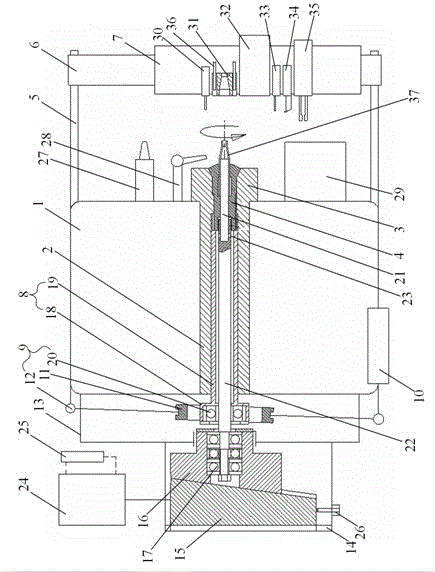

[0058] Such as figure 1 As shown, an automatic processing equipment for small-diameter copper pipes with inner and outer cones and thin-walled circles, including supporting mechanisms, spinning pipe inner cone actuators, integral spinner molds for spinning pipe outer cones, mold rotating cleaning heads, and thin-walled circles. Cutting tool and loading and unloading mechanism;

[0059] The supporting mechanism includes a headstock 1, a cylinder 10 installed below the headstock 1, two parallel transverse guide rails 5 are installed on the right side of the headstock 1, the longitudinal guide rails 6 are installed on the transverse guide rails 5, and the servo motor drives the slide table 7 Installed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com