Anti-clogging device, control method and sewage pump

A control method and anti-clogging technology, which are applied in pump control, components of pumping devices for elastic fluids, pumps, etc., can solve the problems of insignificant impurity treatment effect, burning down the motor of sewage pump, and reducing pump efficiency, etc. Achieve the effect of improving the efficiency of automated processing, reducing the possibility of blockage, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

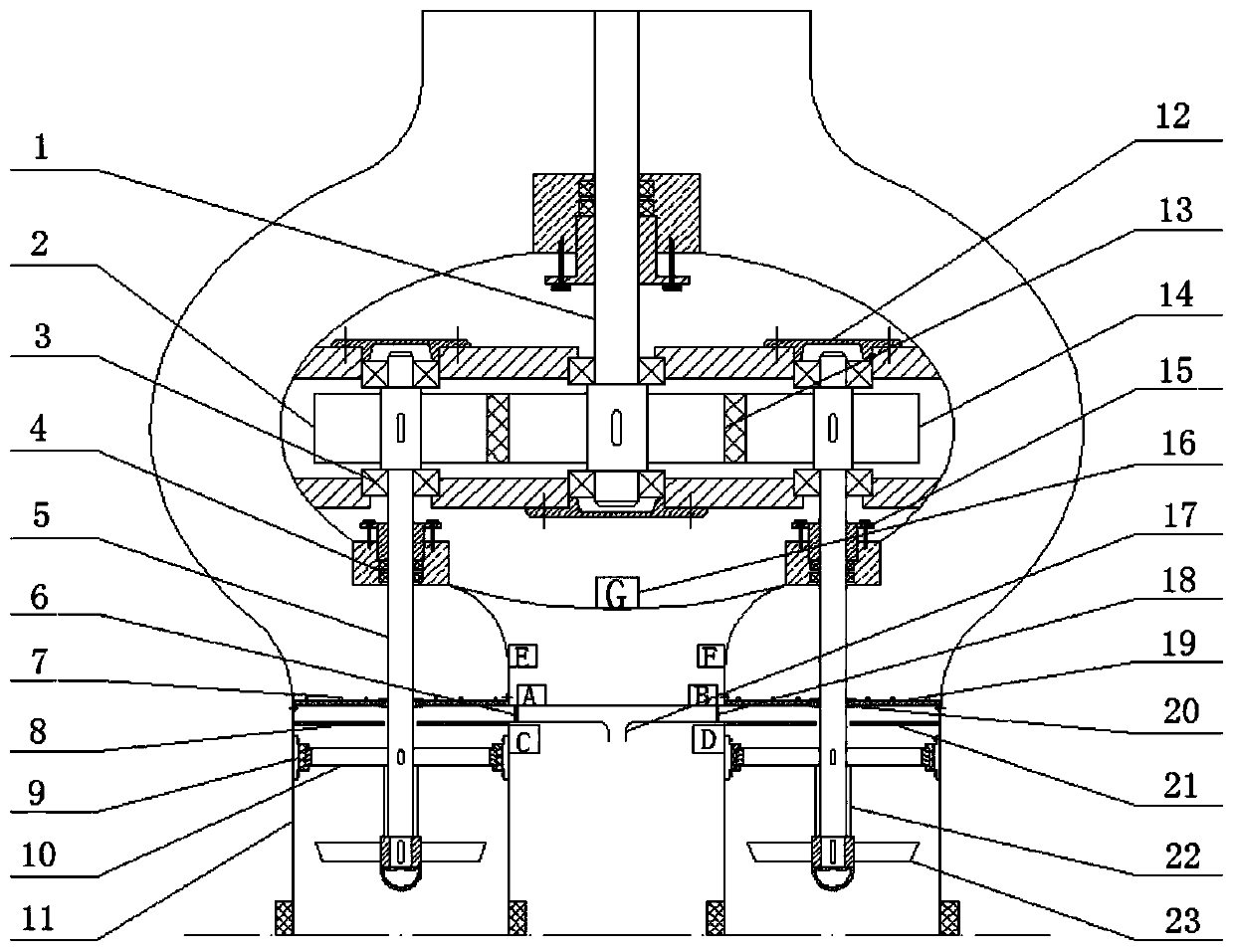

[0037] figure 1 Shown is an embodiment of the anti-clogging device of the present invention. The anti-clogging device includes two water inlet pipes 11, a debris discharge pipe 17, an impeller 23, a motor shaft 1, a filter screen 19, a pressure sensor 7, First valve, second valve, gear clutch and controller.

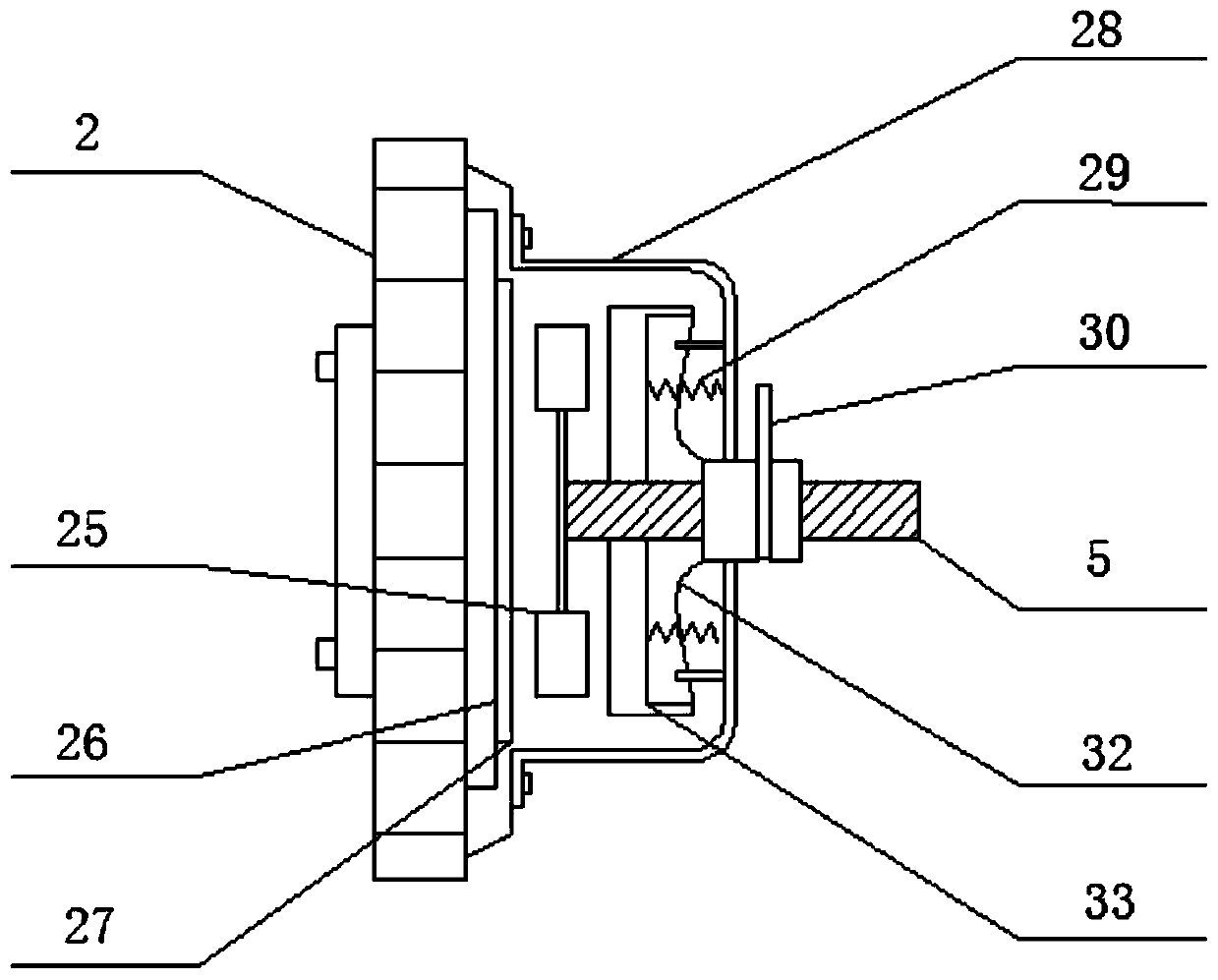

[0038] The water inlet ends of the water inlet pipes 11 are respectively provided with impellers 23, and the water outlet ends of the two water inlet pipes 11 are connected; The gear train connection of the output end of the motor shaft 1. The gear train includes a driving gear and a driven gear; the output end of the motor shaft 1 is provided with a driving gear 13; the driving gear is at least connected with two driven gears; the driven gear is connected to the impeller shaft through a gear clutch 5 connections. Specifically, the driven gear includes a driven gear A2 and a driven gear B14.

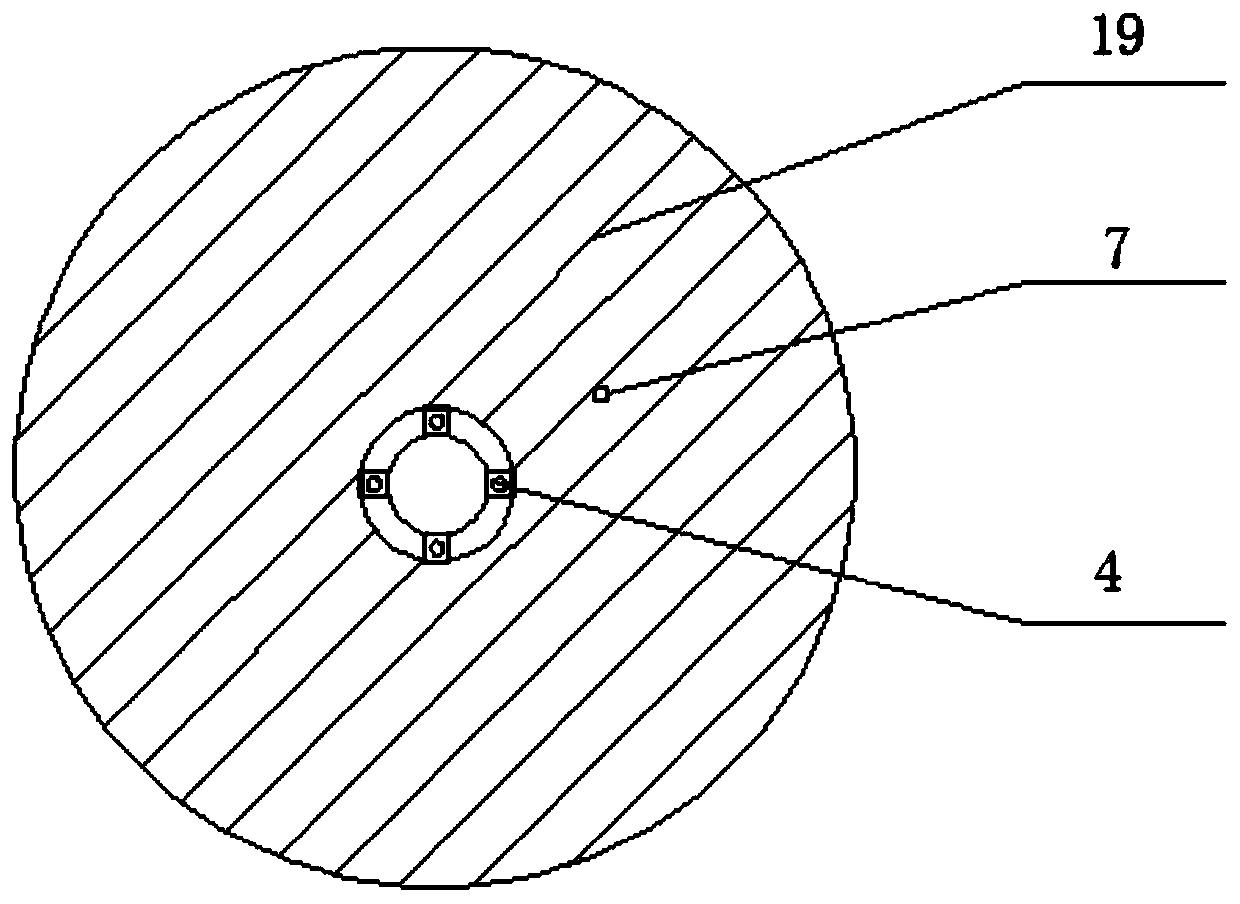

[0039] The filter screen 19 is installed at the water inlet end of the wat...

Embodiment 2

[0060] A sewage pump includes the anti-clogging device described in Embodiment 1, so it has the beneficial effects of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com