Forced oil injection lubrication system for open gear of walking box of coal mining machine

A technology of oil spray lubrication and shearer, which is applied in the direction of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc. It can solve the problems of multiple refueling, easy blockage of the oil drip port, and non-use, etc., to improve the service life , to ensure reliable operation and stability, and to reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

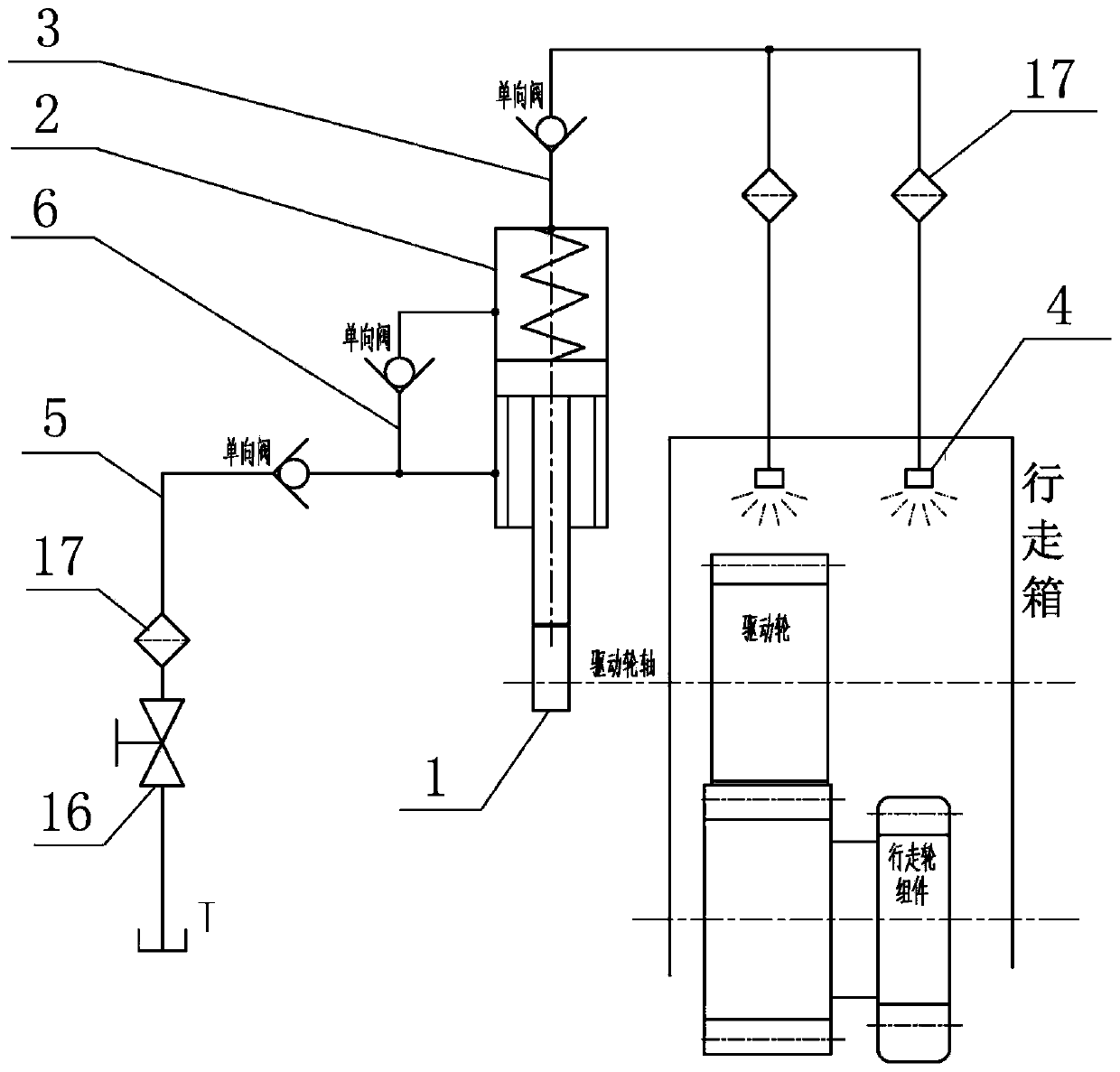

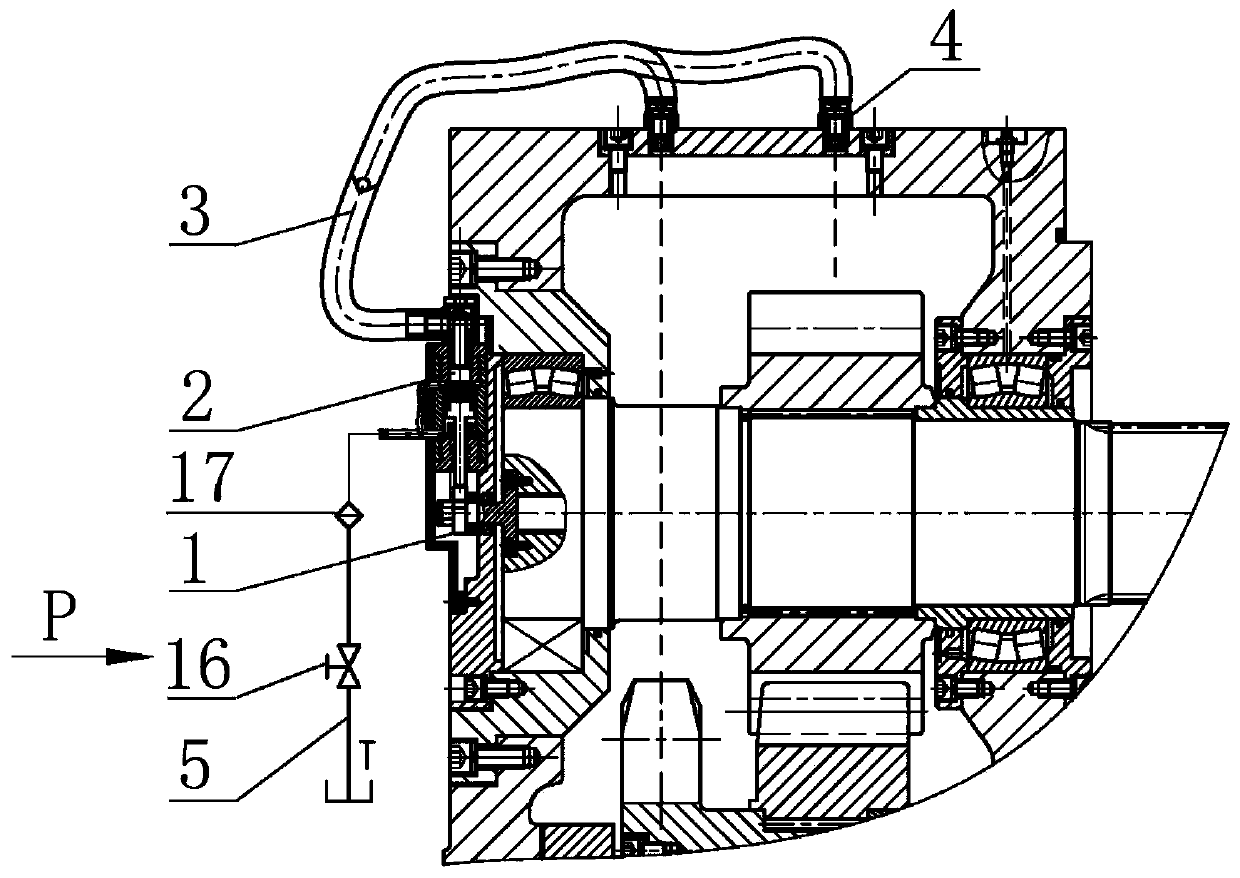

[0030] The invention discloses a forced oil injection lubrication system (referred to as the oil injection lubrication system) of an open type gear in the traveling box of a coal mining machine, such as Figure 1-5 As shown, it includes a cam 1 and a spring return single-acting piston cylinder 2, the spring 2-1 of the single-acting piston cylinder is located in a chamber of the cylinder 2-4, and the spring chamber is connected to the nozzle device through the oil discharge line 3 4. The springless chamber is connected to the lubricating oil source through the oil inlet pipeline 5, and the spring chamber and the springless chamber are connected through the bypass pipeline 6 located outside the piston cylinder chamber. Described cam coaxially is fixed on the driving wheel axle 7 of coal mining machine walking box or the walking wheel axle, and the embodiment shown in the accompanying drawing is installed on the driving wheel axle. The single-acting piston cylinder is arranged pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com