Blast hole forming structure for cutting blasting of small section roadway

A technology with layout structure and small section, applied in blasting, tunnel, mining equipment and other directions, can solve the problems of large blasting clamping effect, small cutting depth, difficult to meet cutting requirements, etc., to achieve low explosive consumption and drilling. A small number, the effect of which is conducive to throwing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

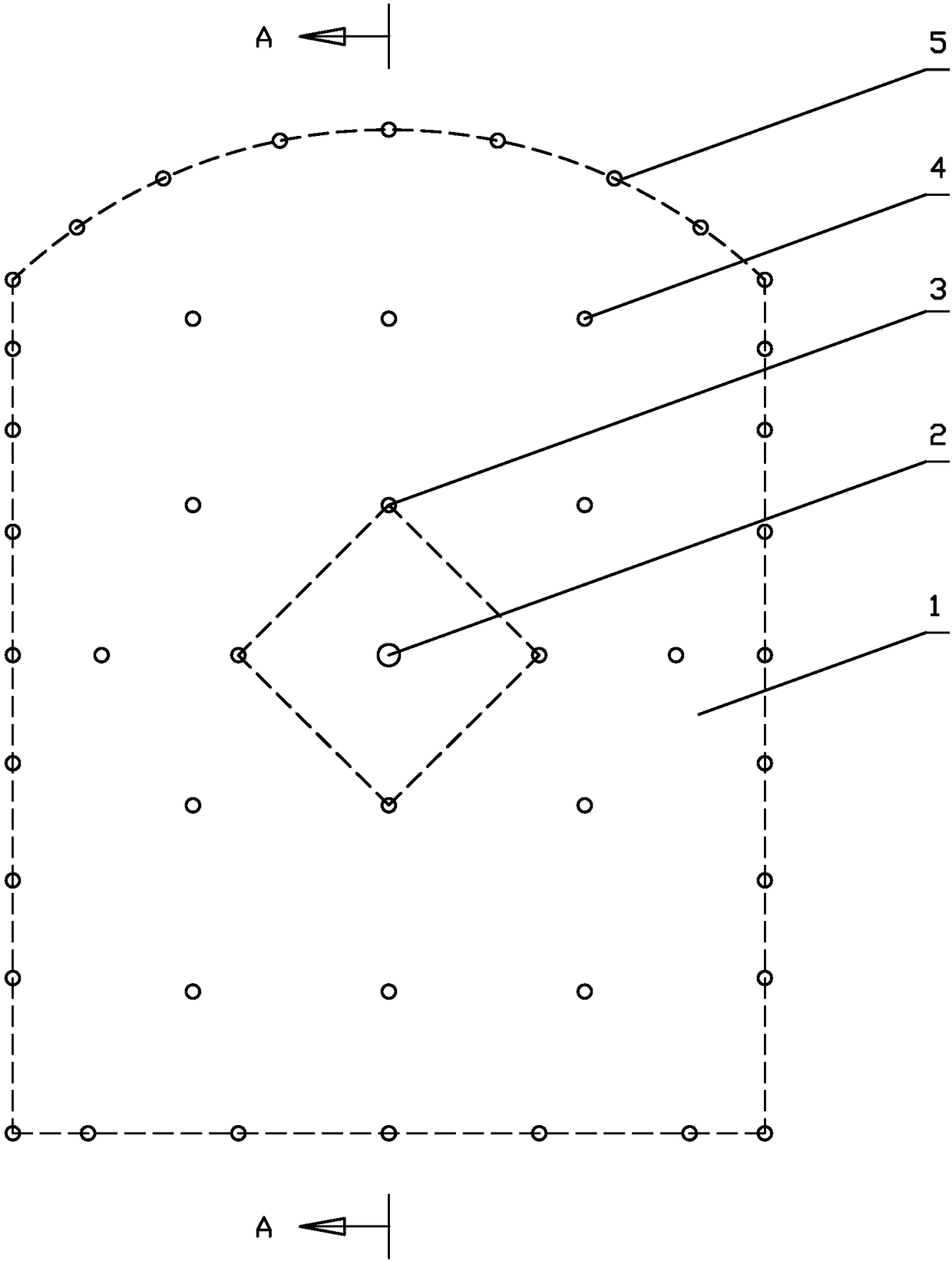

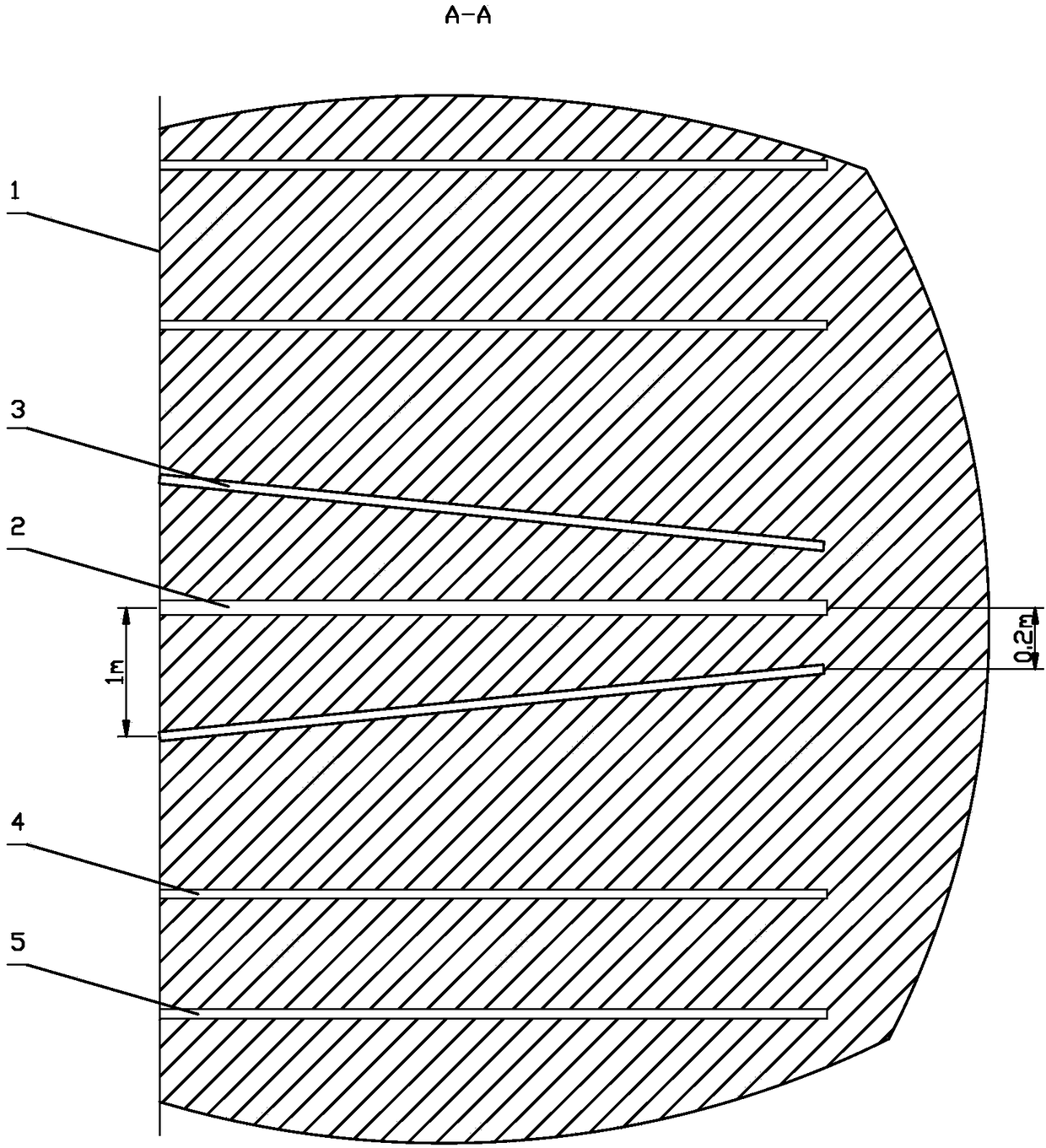

[0018] The blast hole arrangement structure of small-section roadway cutting blasting, which includes a central hole 2 arranged in the center of the roadway driving face 1 and cut holes 3 arranged around the center hole 2, and auxiliary holes 4 are arranged around the cut hole 3, Peripheral holes 5 are arranged on the edge of the design section of the roadway excavation face 1;

[0019] The hole direction of the auxiliary hole 4, the peripheral hole 5 and the central hole 2 is the same as that of the roadway cutting;

[0020] The cut hole 3 gradually converges toward the central hole 2 from the opening to the bottom of the hole.

[0021] When implementing blasting, no explosives are charged in the central hole 2, and explosives are respectively installed in the cutout hole 3, the auxiliary hole 4 and the peripheral hole 5 to implement the blasting.

[0022] The number of holes, the depth of the holes and the pitch of the cut hole 3 are determined according to the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com