Detachable assembly type column and foundation ductile joint connection mode

A node connection and assembly technology, applied in infrastructure engineering, protected buildings/shelters, building components, etc., can solve problems such as inconvenient construction, quality fluctuations, non-replacement, etc., to increase overall stability, installation Easy, easy-to-replace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

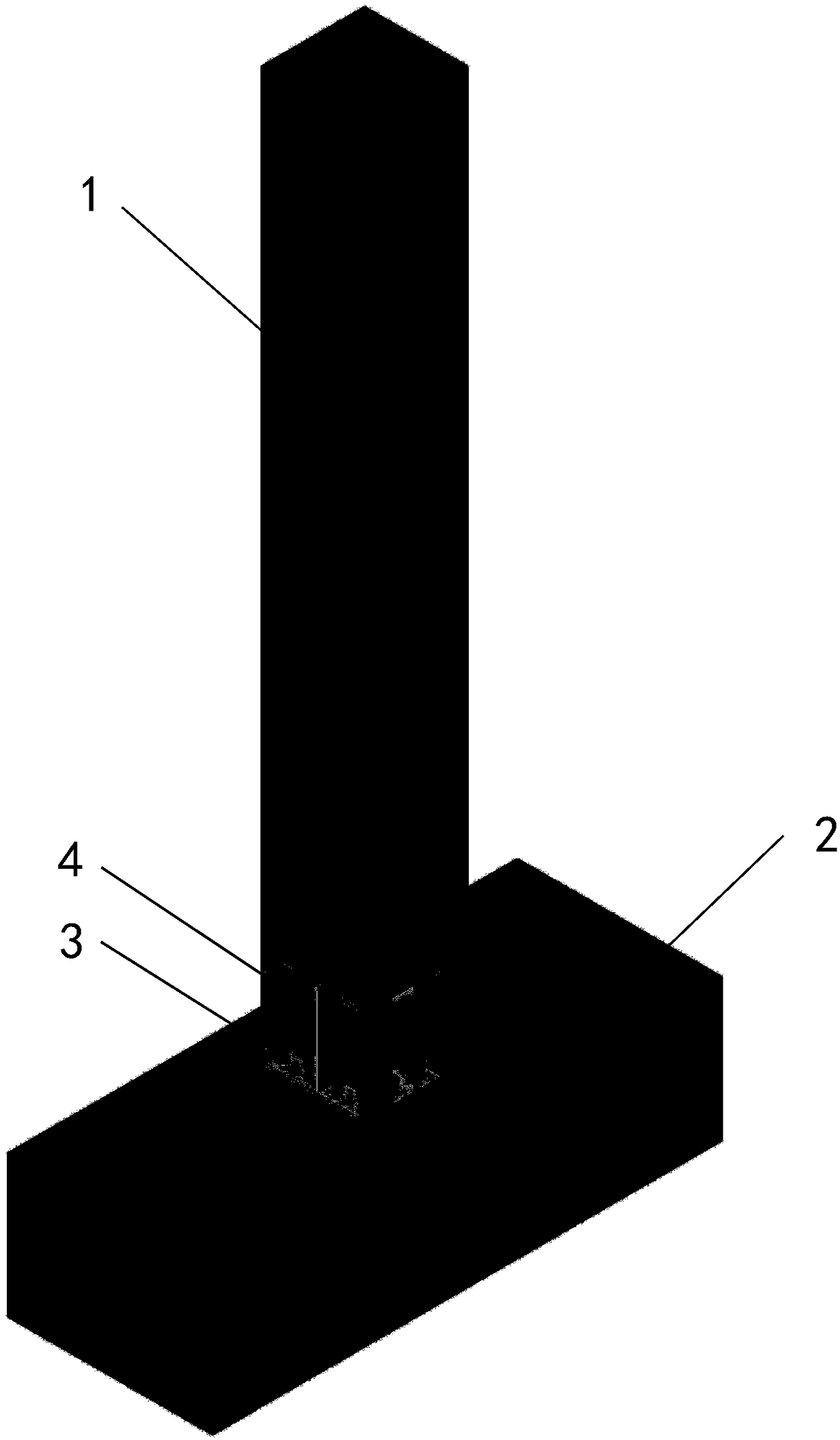

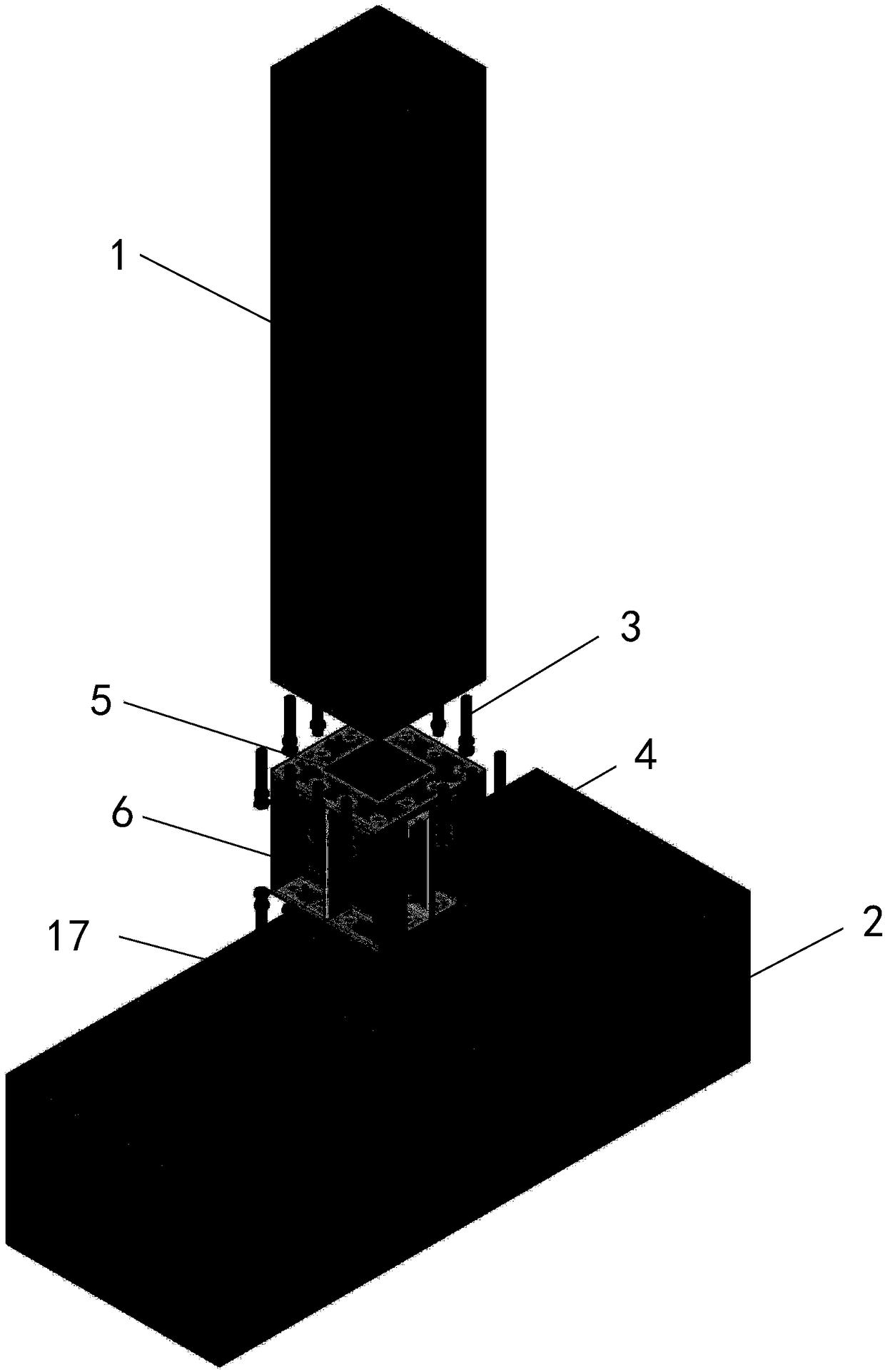

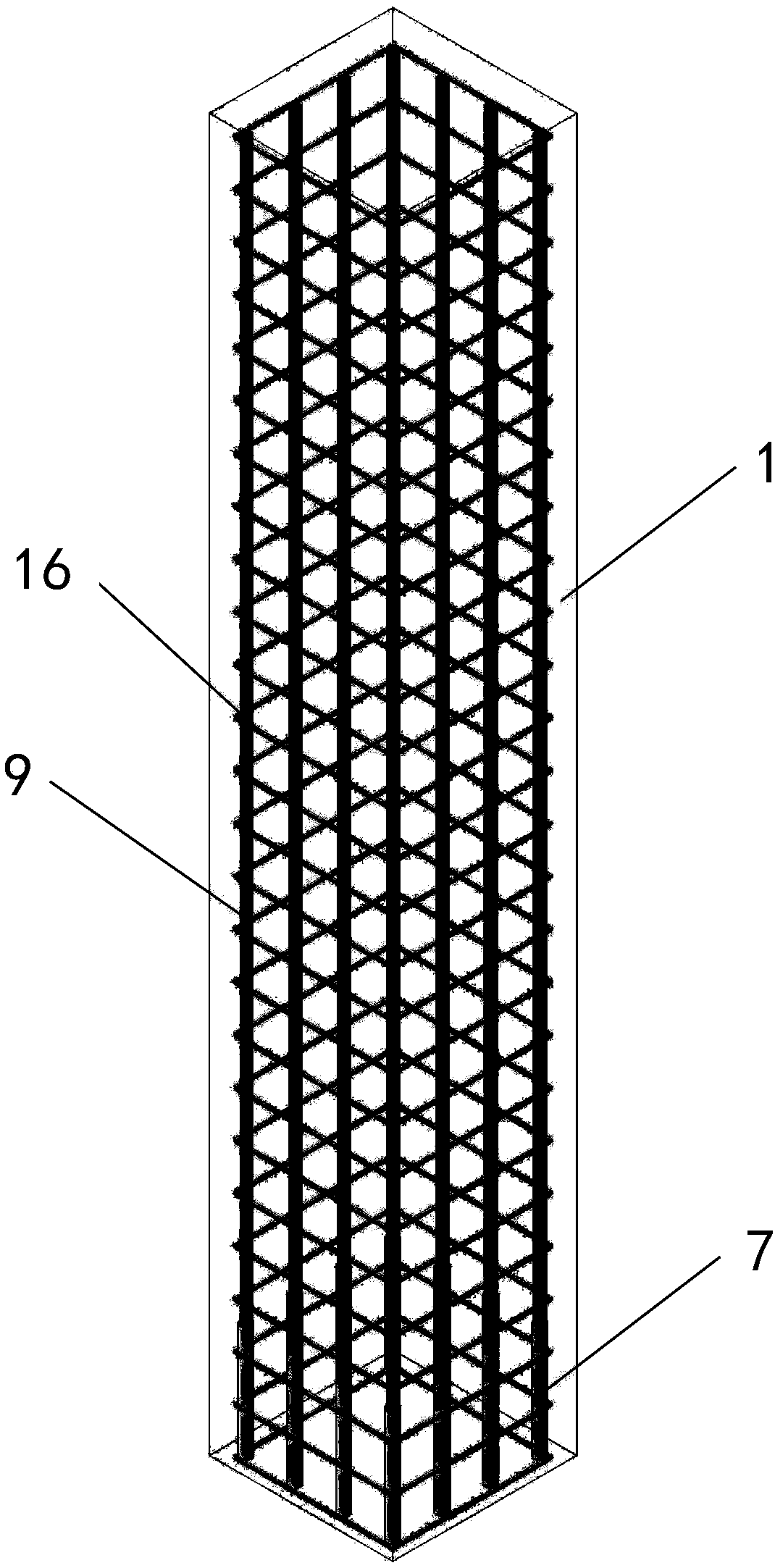

[0041] Such as figure 1 , figure 2 and Figure 4 , a detachable assembled column and foundation ductile node connection method, which includes a reinforced concrete column 1, a reinforced concrete foundation 2, a steel structure connector with good ductility 4, a hexagonal high-strength bolt 3, a vertical stiffener 6, and a concrete block 5 And energy-consuming rubber threaded pipe 15. Preliminary work: factory prefabricated reinforced concrete columns 1, prefabricated reinforced concrete foundation 2, steel structure connecting members 4, and pouring concrete in the steel members to form concrete blocks 5. Before prefabrication, the column longitudinal reinforcement and the internal column longitudinal reinforcement of the foundation are tapped in advance, and the inner wire steel pipe 7 and the inner wire steel pipe 8 with end plates are respectively screwed into the column longitudinal reinforcement and the foundation internal column longitudinal reinforcement, screwed t...

Embodiment 2

[0043] Repeat Example 1, use an electric hexagonal high-strength bolt gun to screw the hexagonal high-strength bolts into the concrete column and the foundation.

Embodiment 3

[0045] Repeat Example 1, the thickness of the upper and lower end plates of the steel structure connector with good ductility is 15 mm, and the length of the energy-dissipating rubber threaded pipe is 15 mm. The diameter of the inner ring of the energy-dissipating rubber threaded pipe is 5-10 mm larger than that of the hexagonal screw.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com